Constant support

A stable and supportive technology, used in pipeline supports, mining equipment, earth-moving drilling, etc., can solve the problem of difficult operation in the working space, and achieve the effect of enhancing the construction method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

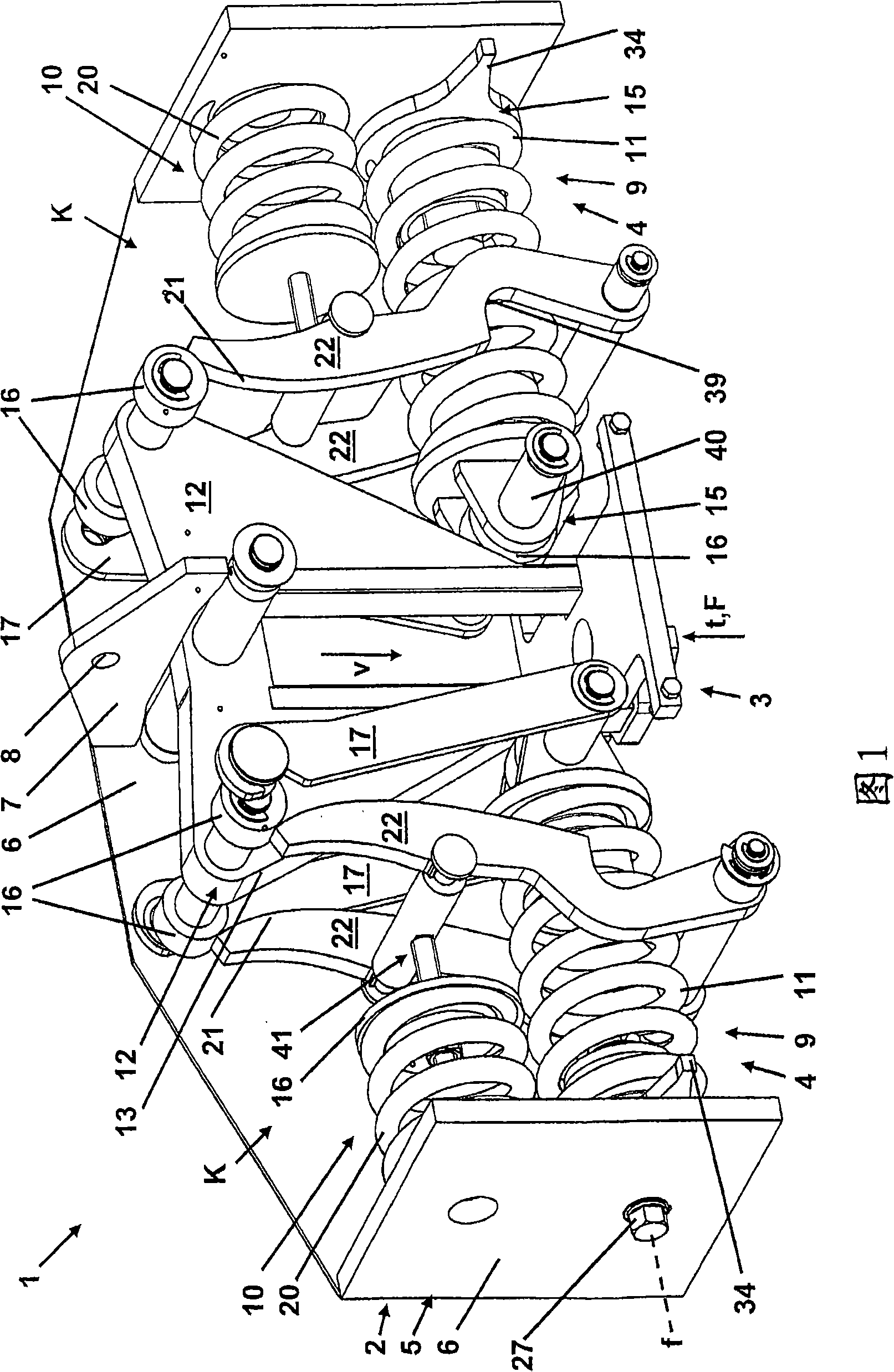

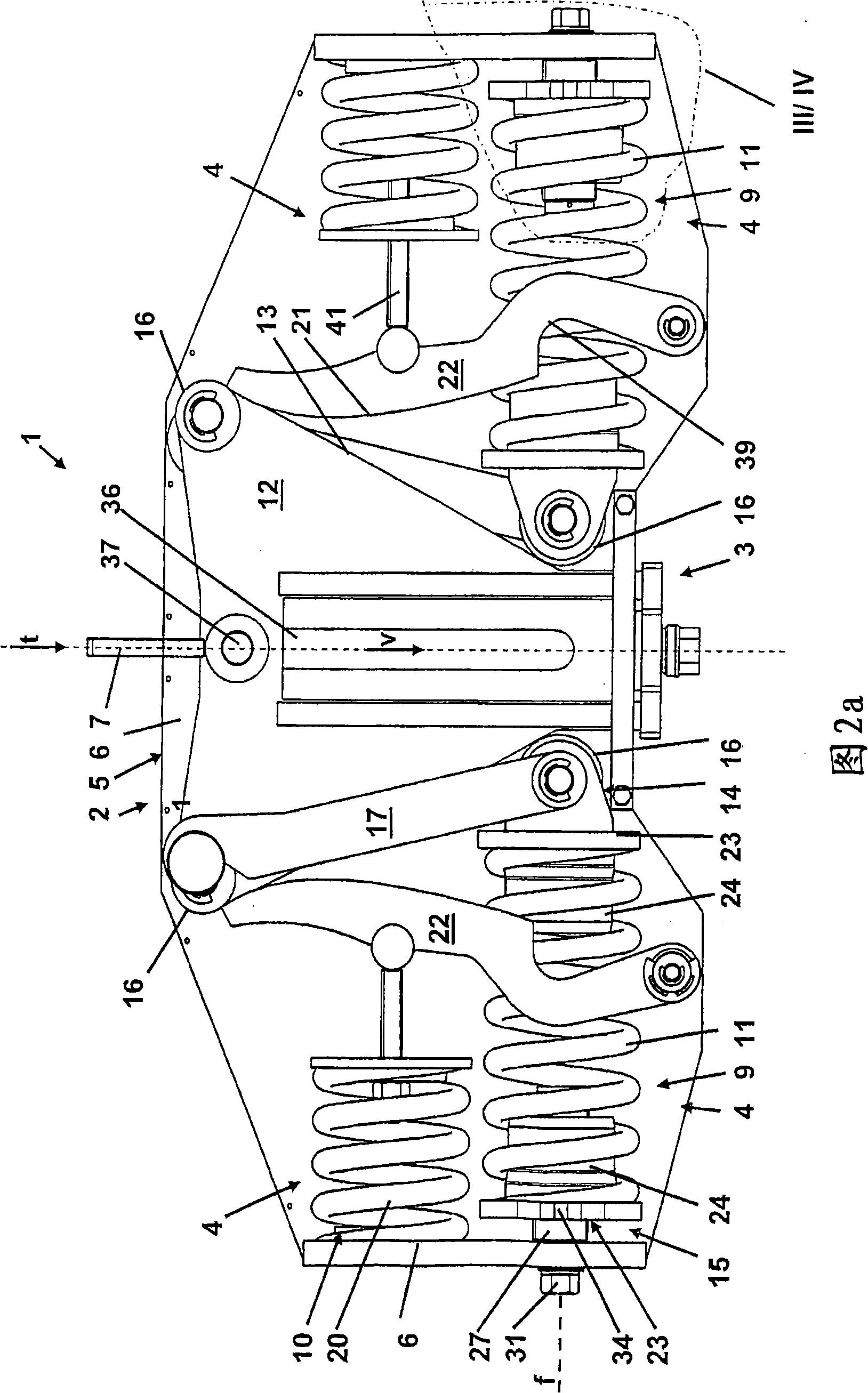

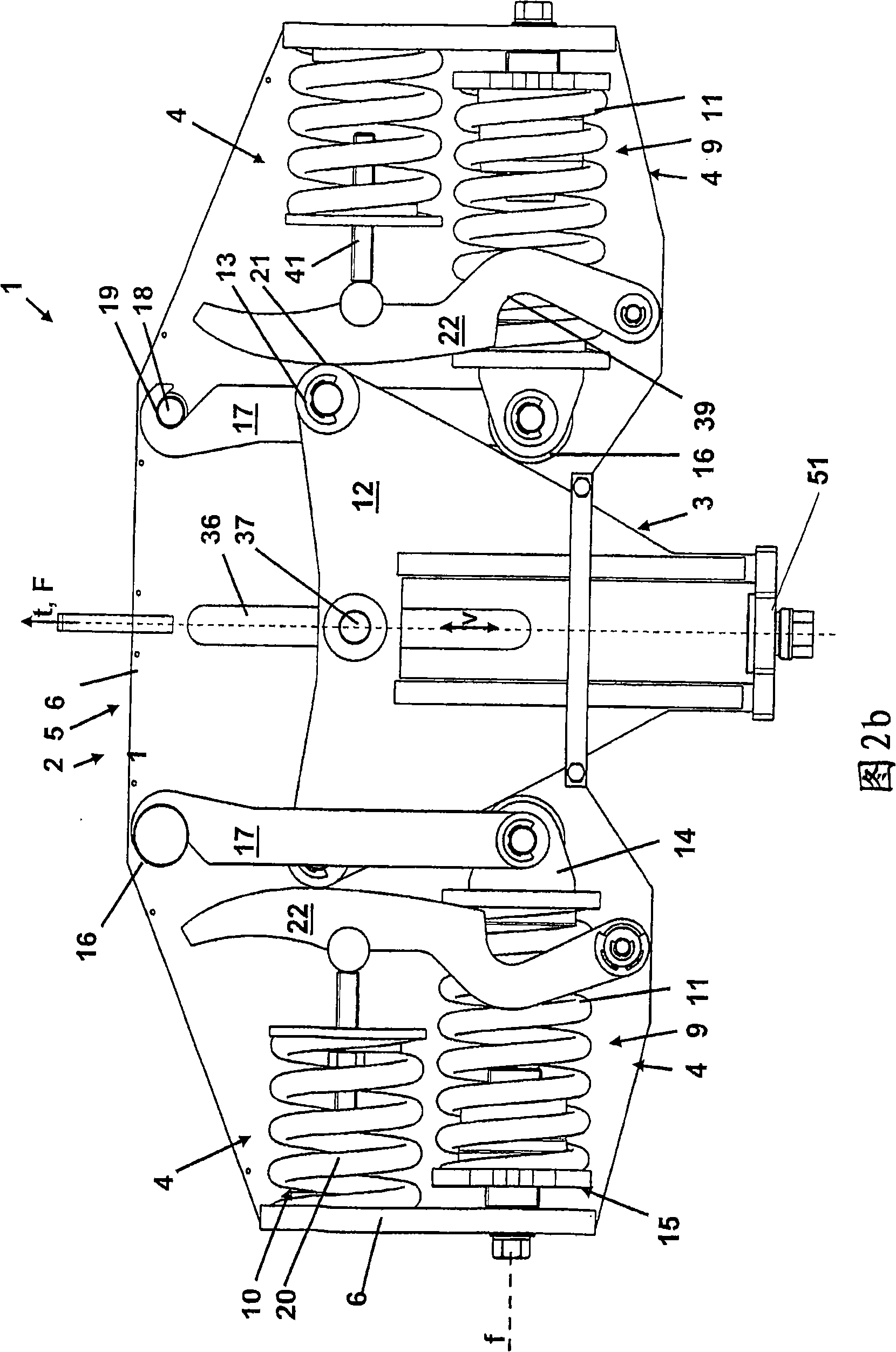

[0059] 1 to 4 show different views of a first embodiment and FIGS. 5 to 8 of a second embodiment of a stabilizing support 1 configured as a stabilizing hanger for use in the drawings. A moving load not shown in the figure, especially for pipes not shown in the figure, etc., comprising a fixed part 2, a load bearing part 3 and a spring system 4 arranged between the fixed part 2 and the load bearing part 3 To create a constant support force. In both embodiments, the spring system each has a compensating device k for compensating the changing pressure of the main spring device 9 .

[0060] In the two embodiments shown in the figures, the stabilizing bracket 1 is designed as a stabilizing hanger, comprising an upper fastening part 2 in the installed position and a downwardly extending load bearing part 3 for suspending loads not shown in the figures. The fastening part 2 has a housing 5 with side walls 6 , the front side walls being omitted in FIGS. 1 to 3 and 5 to 6 for the sake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com