Novel self-stabilizing enclosure system

An enclosure system and self-stabilizing technology, applied in sheet pile walls, excavation, construction, etc., can solve problems such as limited space use, impact on operating space, and prolonging the construction period of the project, so as to save construction period and construction space , The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

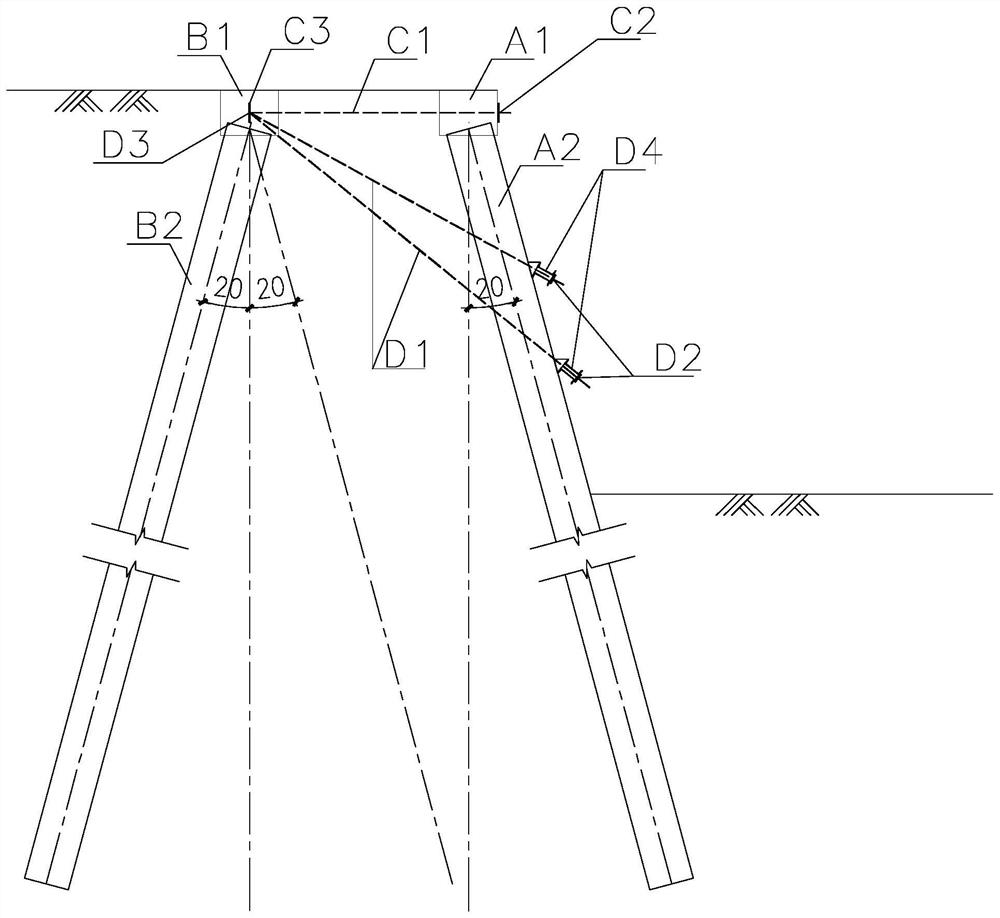

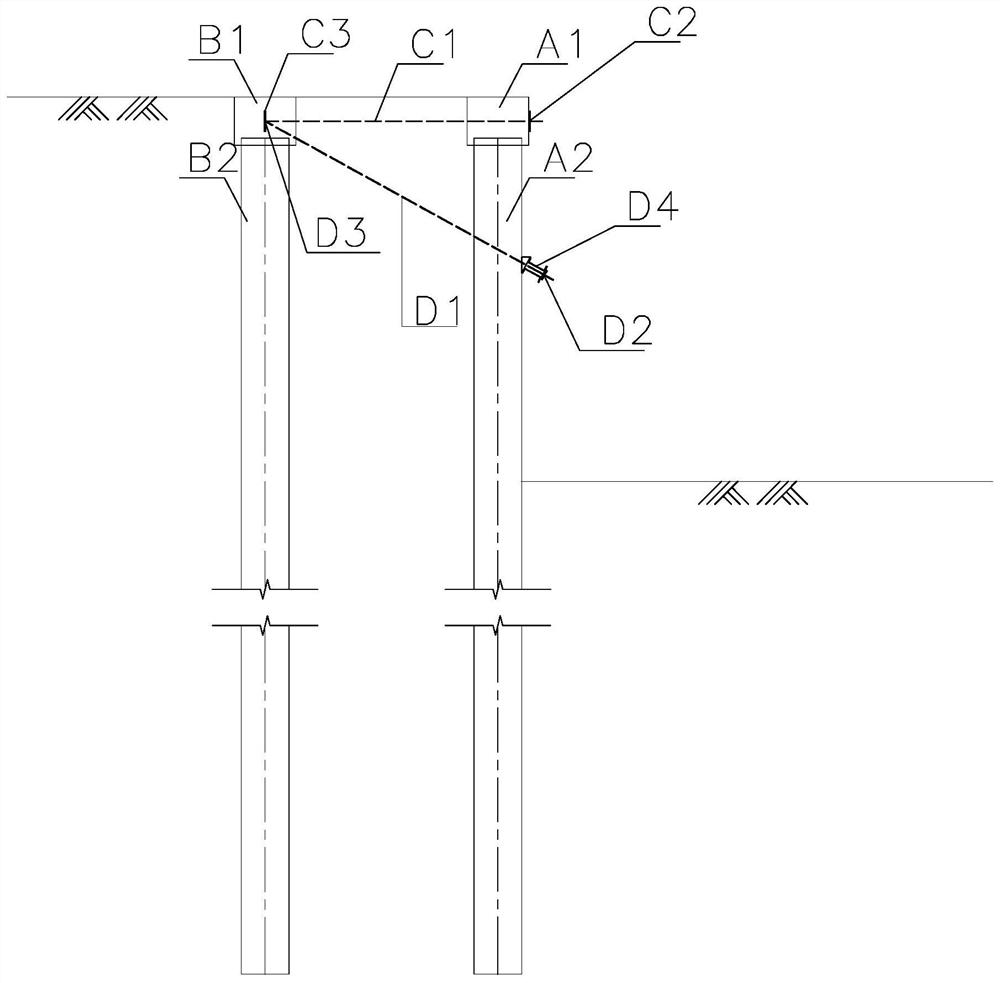

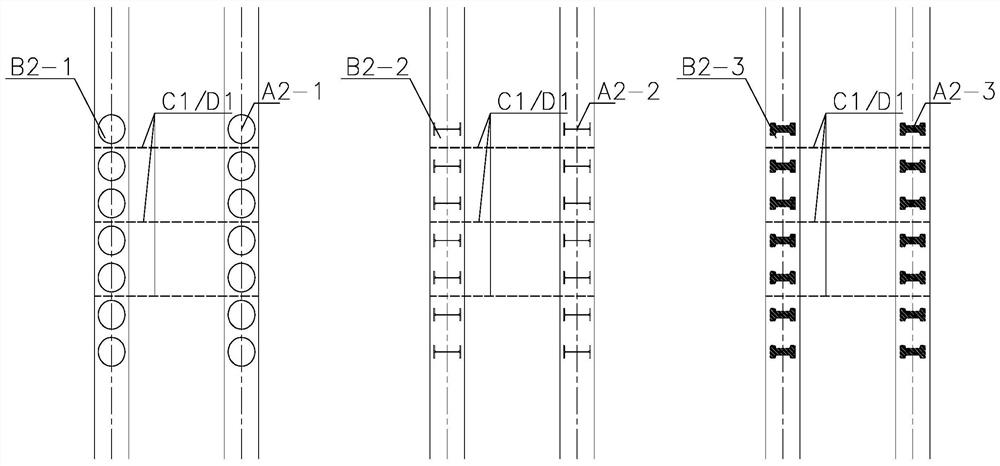

[0022] Such as Figure 1~3 As shown, a novel self-stabilizing enclosure system, the novel self-stabilizing enclosure system includes a front row enclosure component A2, a rear enclosure component B2 and an anchor cable; the front row enclosure component A2 passes through the front The crown beam A1 is connected; the rear enclosure member B2 is connected to B1 through the rear crown beam; the front crown beam A1 is connected to the rear crown beam B1 through a horizontal anchor C1 cable; the front row enclosure member A2 is connected through a cable-stayed anchor The cable D1 is connected with the back crown beam B1.

[0023] The present invention relates to a novel self-stabilizing enclosure system, the construction steps of which are as follows:

[0024] 1. Construction positioning and setting out;

[0025] 2. Positioning of construction machinery, constructing the front row of enclosure components A2 and the rear row of enclosure components B2;

[0026] 3. Slot excavation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com