A cleaning device for floor heating pipeline installation

A pipeline installation and cleaning device technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, and drying solid materials without heating. It can solve the problems of inability to clean the intensity adjustment and poor cleaning effect of floor heating pipes, so as to prevent wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

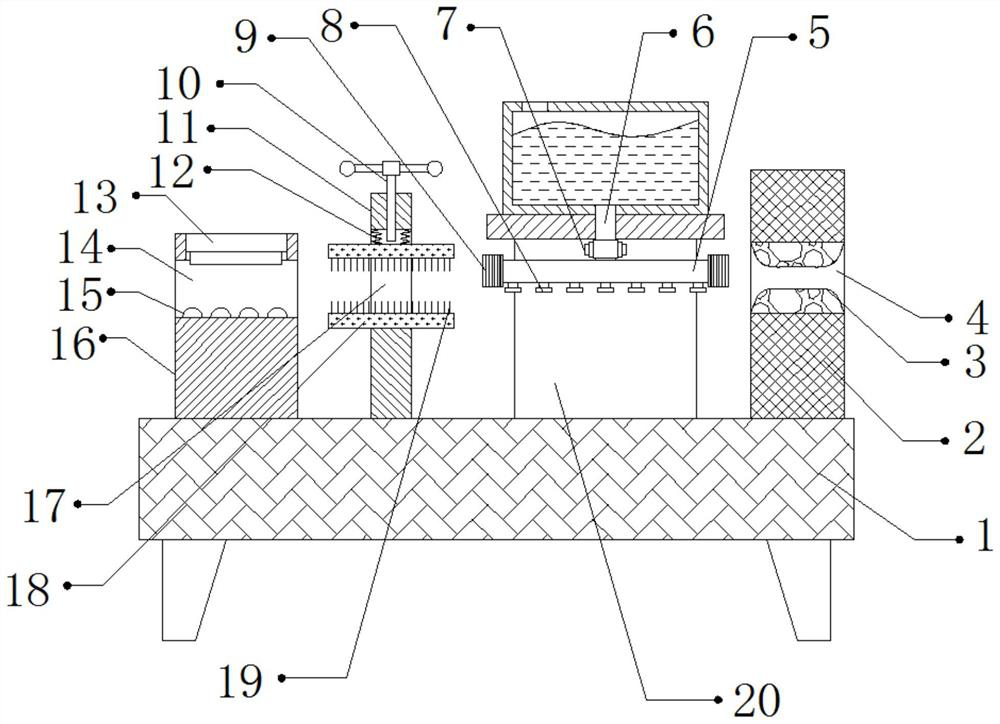

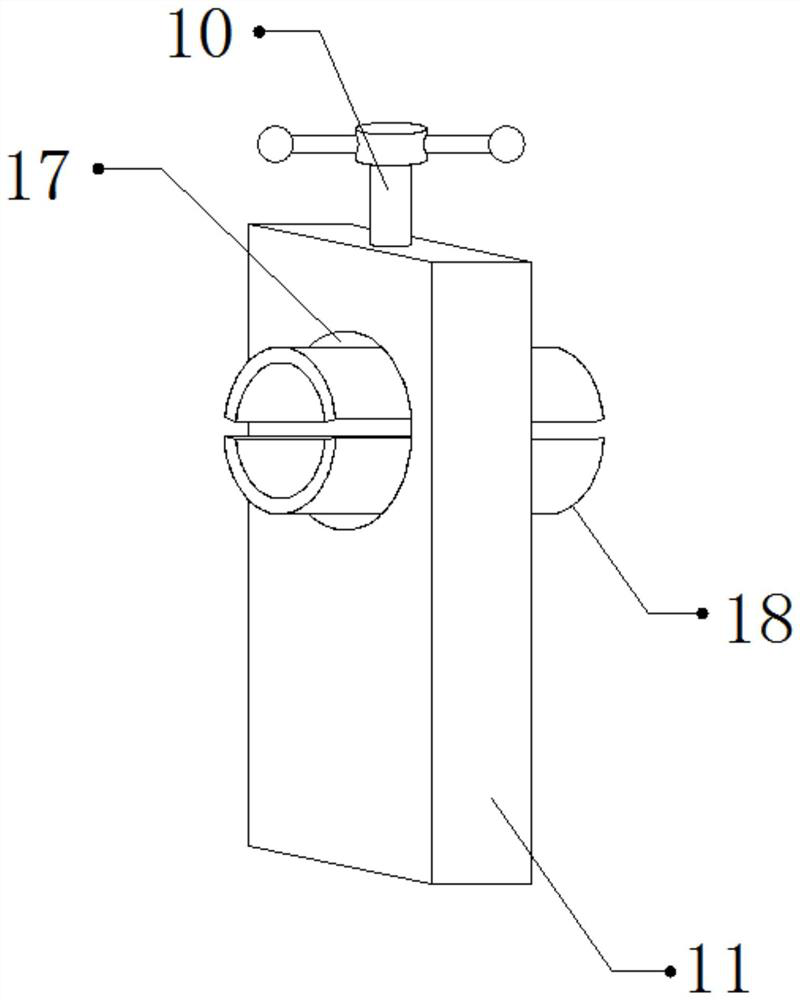

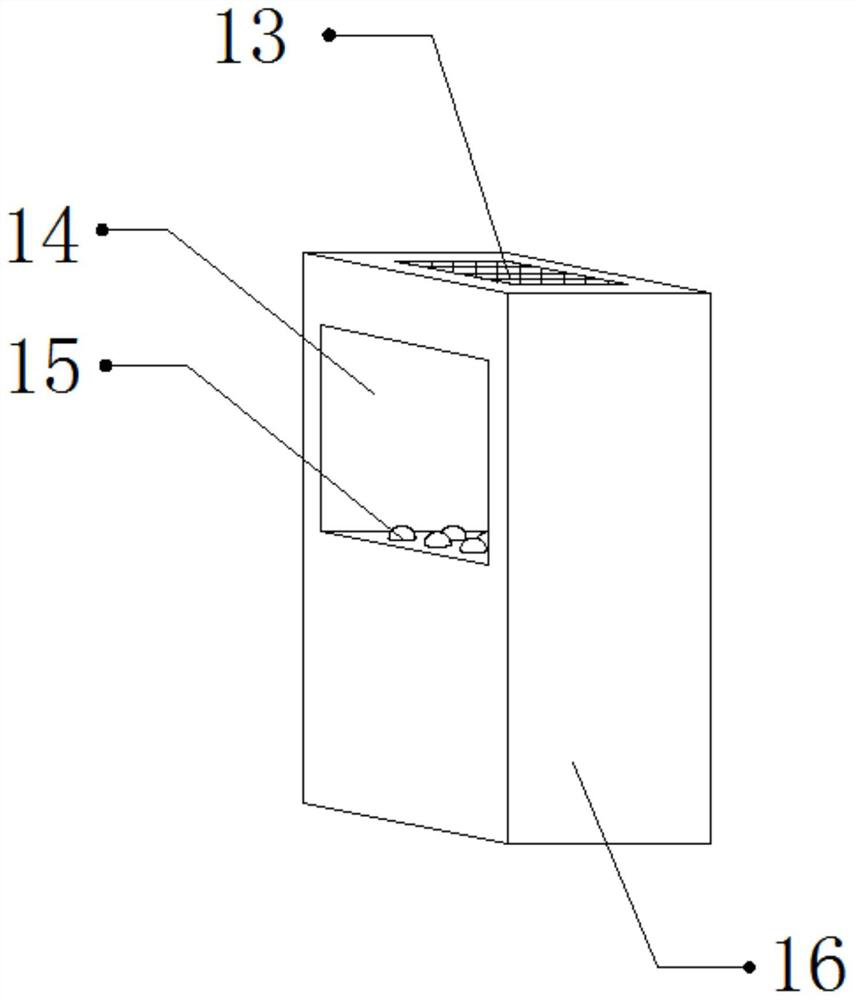

[0026] refer to Figure 1-3 , a cleaning device for installing floor heating pipes, comprising a fixed base 1, one side of the top outer wall of the fixed base 1 is connected with a fixed plate 11 by bolts, and one side outer wall of the fixed plate 11 is provided with a fixed opening 17, and the inner wall of the top of the fixed opening 17 Both sides of the spring 12 are connected with springs 12 by bolts, and the bottom outer walls of the two springs 12 and the bottom inner walls of the fixed opening 17 are connected with splints 18 by bolts, and the outer walls on the opposite side of the two splints 18 are all connected by bolts. Brush 19, the top inner wall of fixed opening 17 is provided with threaded hole, and the inner wall of threaded hole is threadedly connected with threaded rod 10, and one side of fixed base 1 top outer wall is connected with fixed frame 20 by bolt, and the top outer wall of fixed frame 20 passes through Bolts are connected with a liquid storage t...

Embodiment 2

[0034] refer to Figure 4 , a cleaning device for installing floor heating pipes. Compared with Embodiment 1, in this embodiment, vibration motors 21 are connected to both sides of the bottom outer wall of the fixing seat 1 through bolts, and the vibration of the vibration motor 21 can drive the floor heating pipes to shake. Thereby, the water stain adhering to the surface of the floor heating pipe can be dried, and in addition, the stain can be discharged from the floor heating pipe through vibration.

[0035]Working principle: When in use, one end of the floor heating pipe to be cleaned passes through the through port 14, the fixed port 17 and the rectangular port 4 respectively, and the dust adhering to the surface of the floor heating pipe can be preliminarily treated by the fan 13, and the dust adhered to the surface of the floor heating pipe can be preliminarily treated by the ball 15. It can reduce the friction between the floor heating pipe and the port 14, prevent the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com