Temper mill transmission side segmented linear guide rail roller replacement transverse moving device and using method thereof

A linear guide rail and segmented straight line technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of hidden derailment of slider, large thrust, high failure rate of roll change, etc., to ensure stability The effect of stability, reducing the risk of damage, and facilitating on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

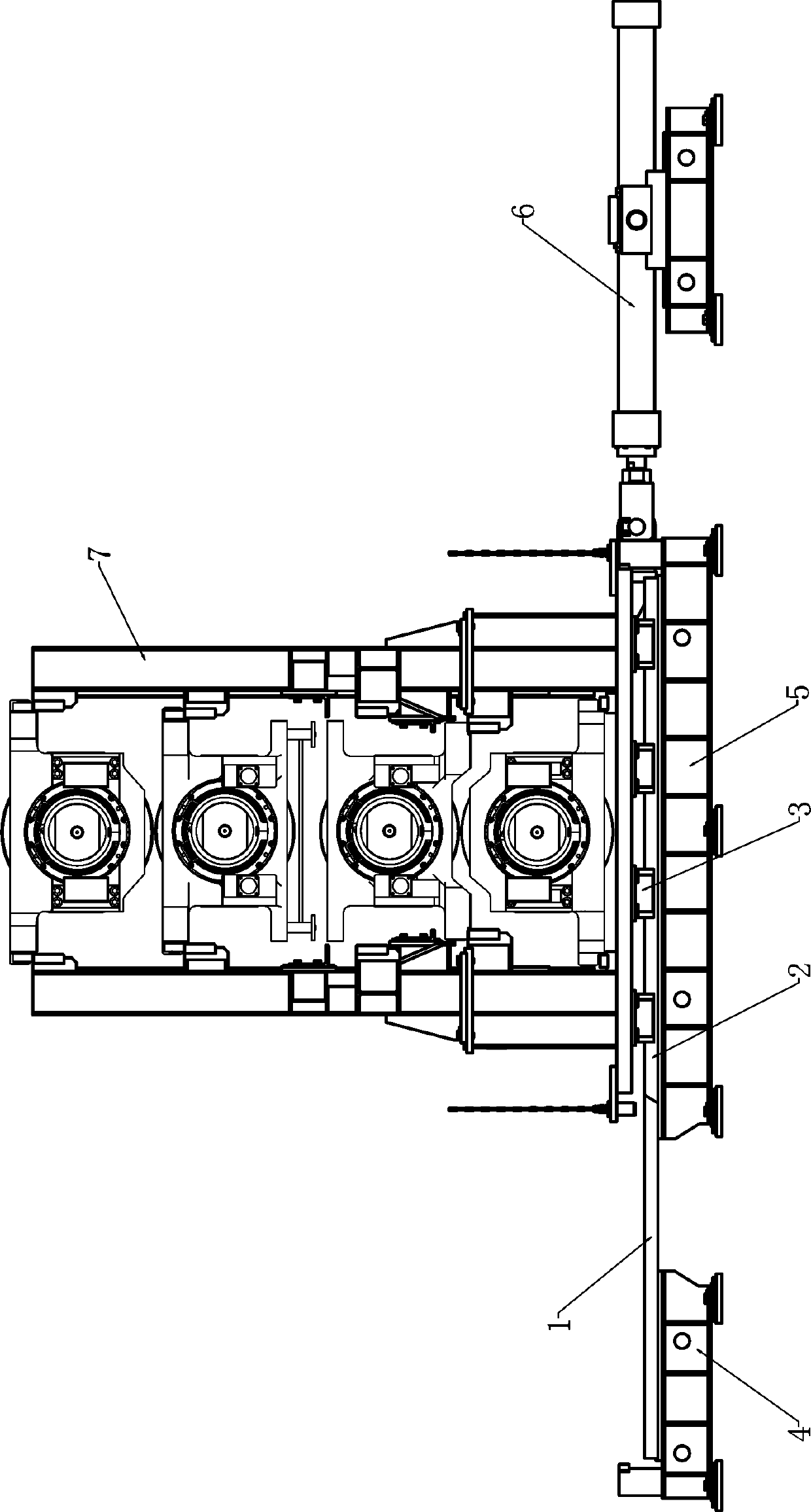

[0024] A roller-changing device for segmented linear guide rails on the transmission side of a skin pass mill, comprising a first linear rail 1, a second linear rail 2, a linear guide slider 3, a first rail bracket 4, a second rail bracket 5, a horizontal Move the push-pull hydraulic cylinder 6 and the roll-changing roll frame car 7, such as figure 1 As shown, the specific structure is:

[0025] The first track support 4 and the second track support 5 are arranged on the operation side of the grader in turn, the first linear guide 1 is fixed on the first track support 4 with bolts, and the second linear guide 2 is fixed on the second track support with bolts 5, and the first linear guide rail 1 and the second linear guide rail 2 are on the same straight line, the center point of the first linear guide rail 1 is aligned with a roller position on the transmission side of the grader, and the second linear guide rail The center point of 2 is aligned with the other roller position...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap