Accurate tool setting device and tool setting method

A tool setting device and precise technology, applied in the field of parts processing, can solve the problems of low precision, affect production efficiency and product quality, and inconvenient operation, and achieve the effects of improving production efficiency, saving tool setting time, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

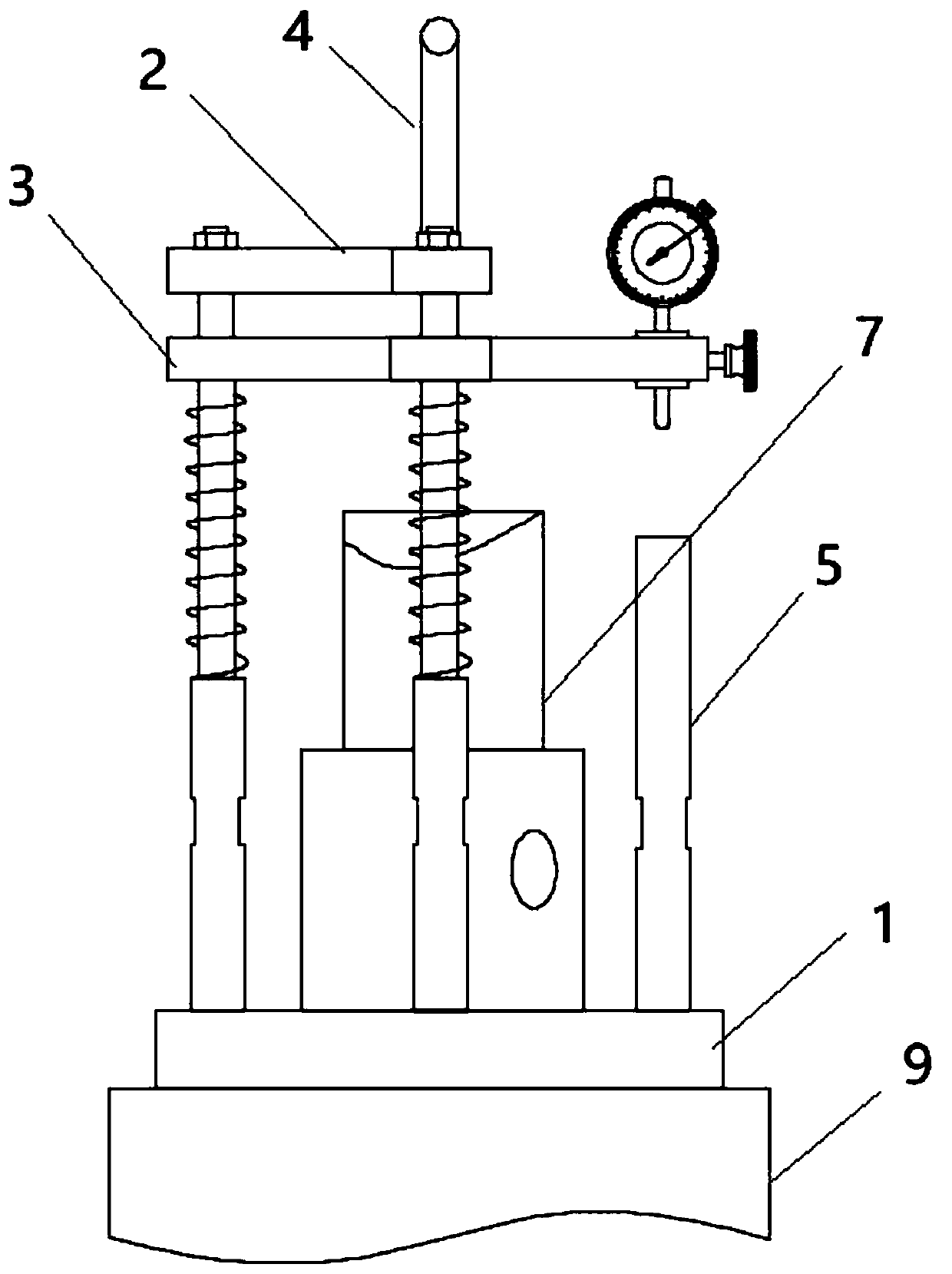

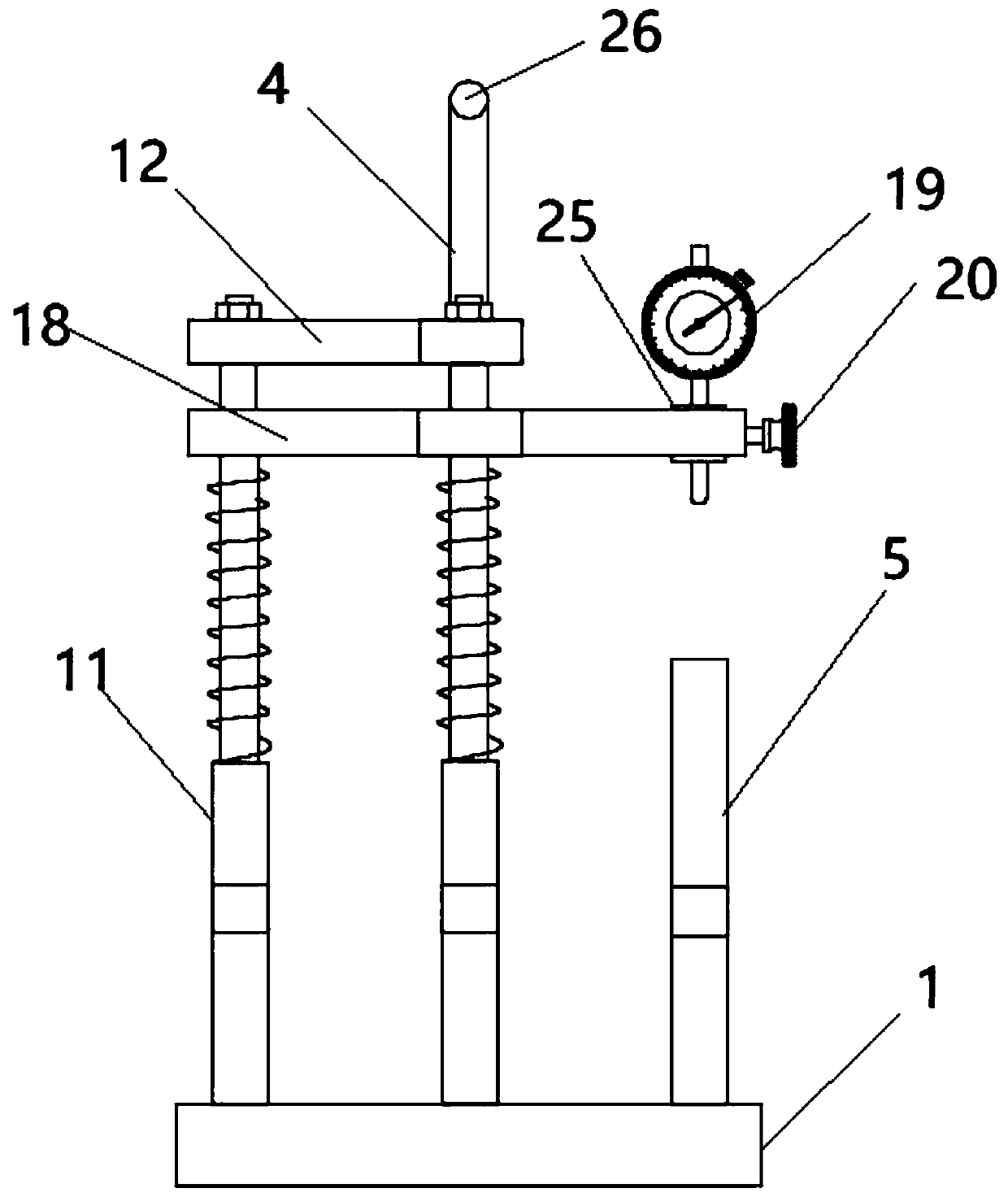

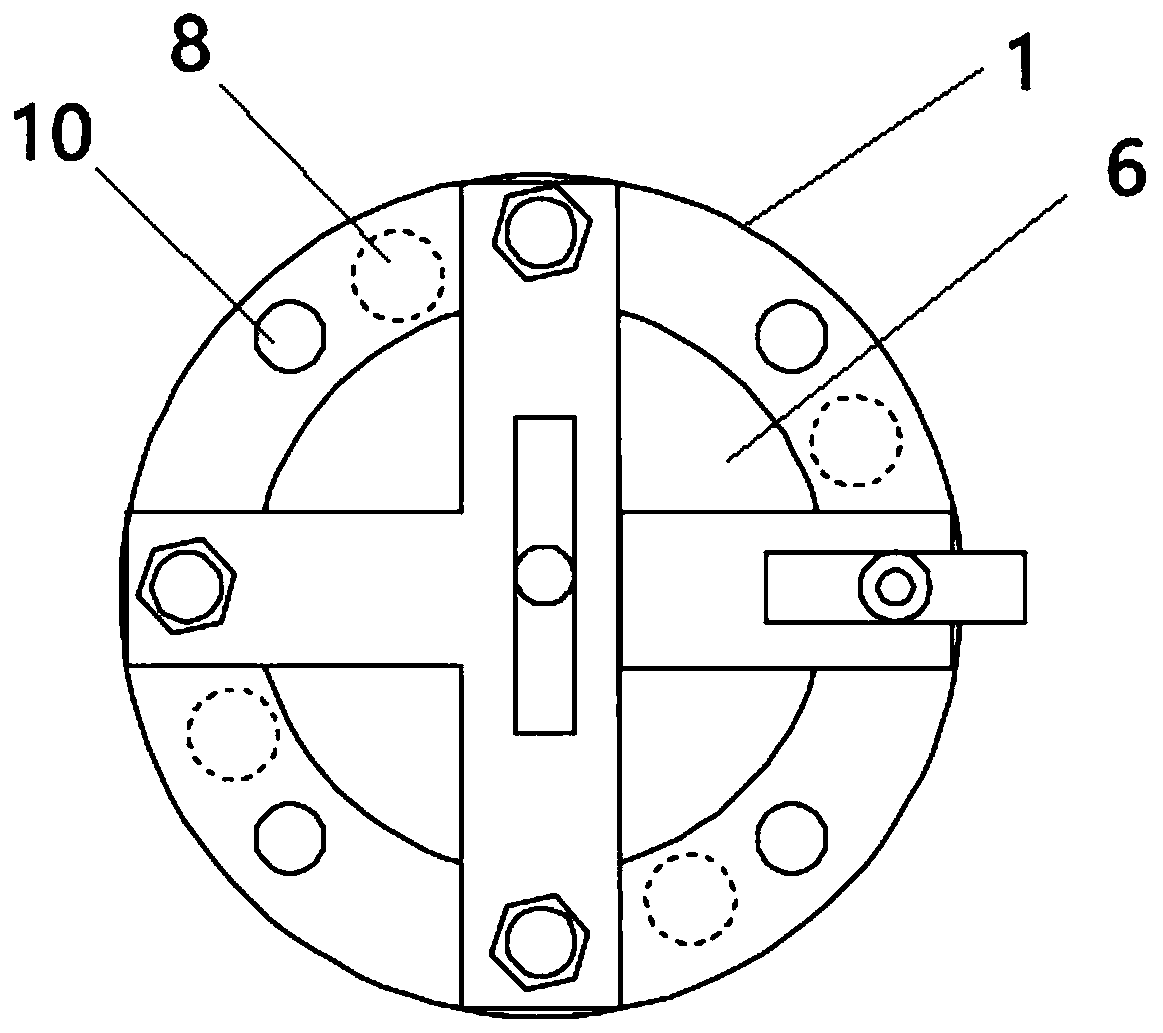

[0026] Such as Figure 1-7 As shown, a precise tool setting device is characterized in that it includes a base 1, a support assembly 2, a measuring assembly 3, a threaded push rod 4, and a measuring rod 5; the base 1 is circular in shape, and the base There is a relief hole 6 in the middle of 1, which is used to make way for the tool 7, and four magnetic blocks 8 are evenly distributed on the bottom of the base 1, which are used to attach the base 1 to the headstock 9 for tool setting. Four magnetic blocks 8 are embedded in the base 1, and eight supporting threaded holes 10 are evenly distributed on the upper part of the base 1, and the eight supporting threaded holes 10 form a regular octagonal shape, which can quickly connect the three supporting rods 11 Installed on the base 1, it also has a lightweight effect; the support assembly 2 includes three support rods 11 and a positioning plate 12; the support rod 11 is a circular rod, and the upper part of the support rod 11 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com