Driving device for optical inspection outside material cabin and exposure platform

A driving device and installation platform technology, which is applied in the direction of analyzing materials, measuring devices, motor vehicles, etc., can solve the problems that the driving mechanism cannot adapt to the space environment, safety and reliability cannot be satisfied, and achieves strong adaptability to special space environments, Realize the effect of all-round monitoring and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

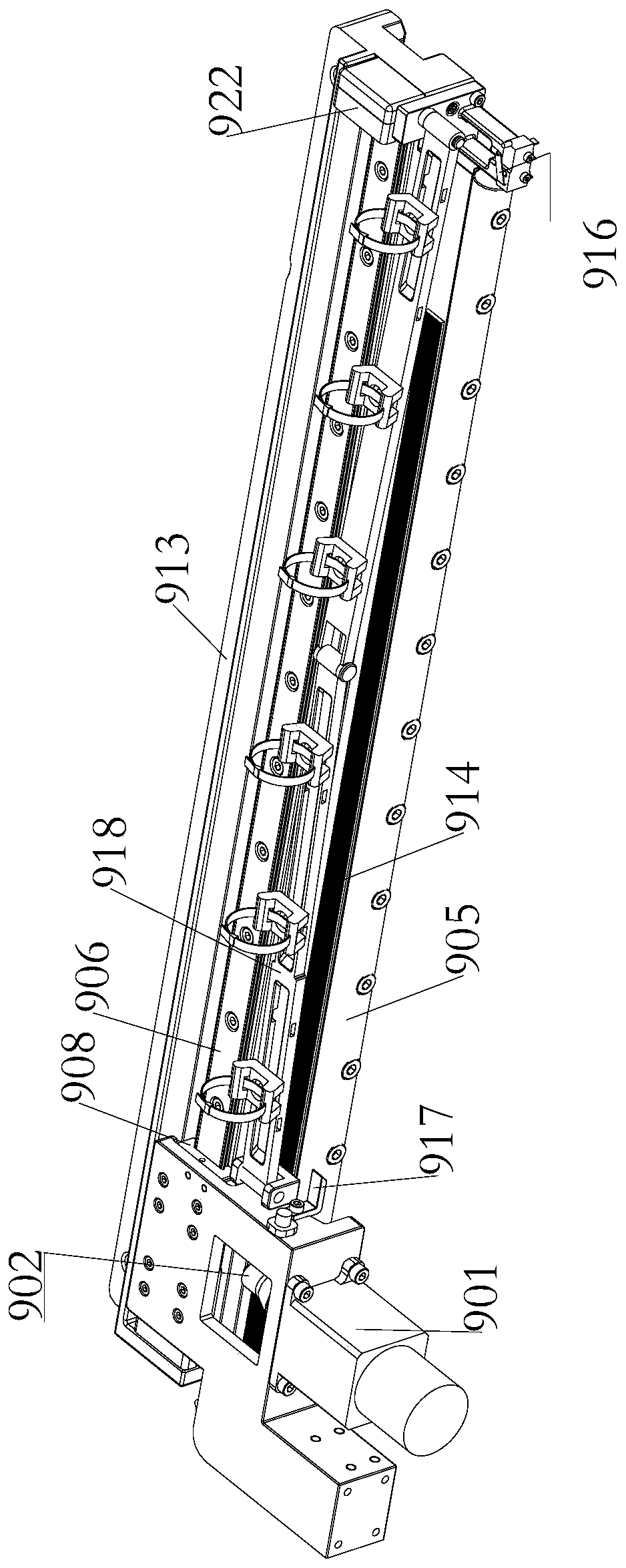

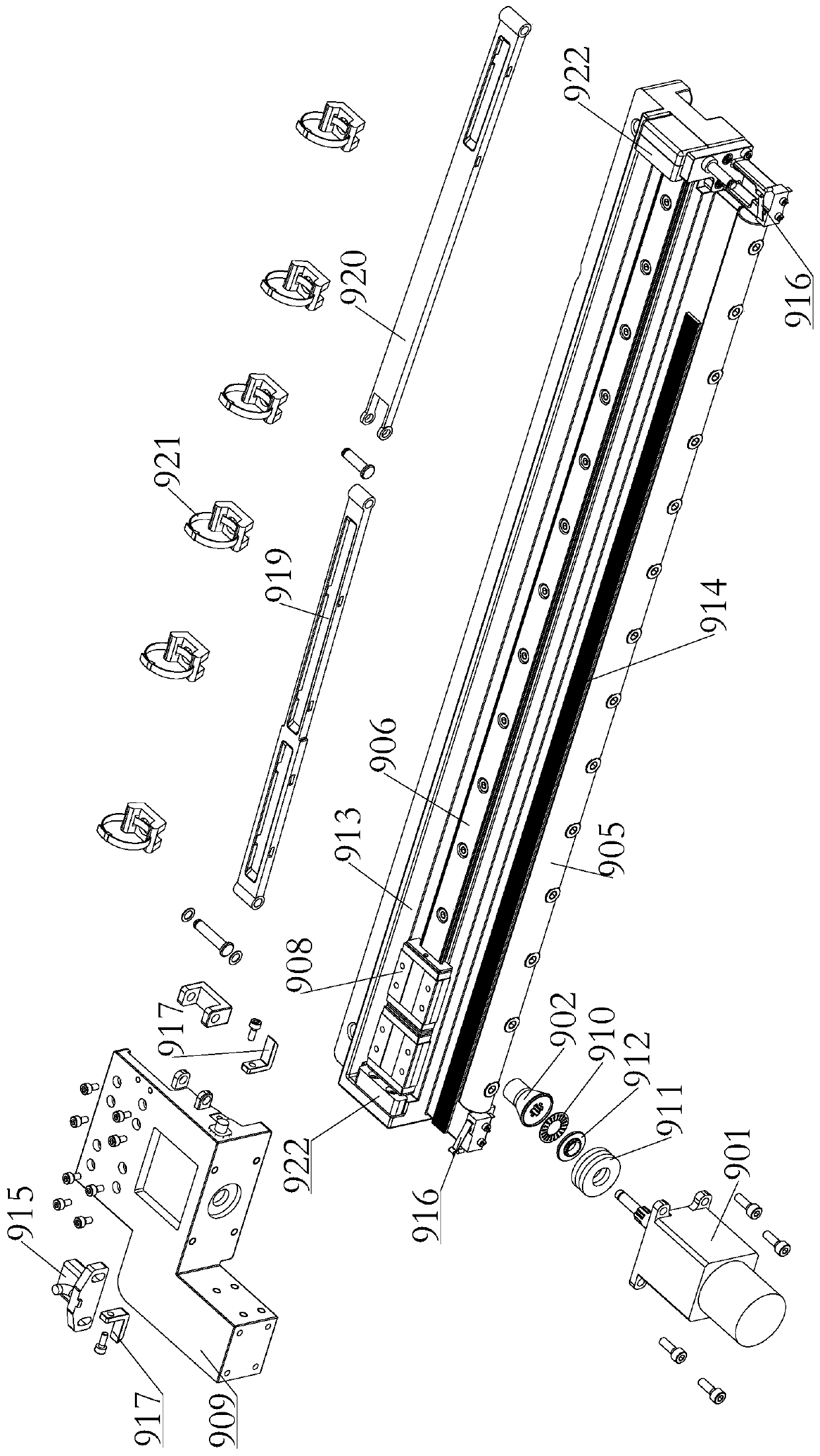

[0075] like Figure 1-Figure 11 As shown, a driving device for optical inspection of materials outside the cabin in this embodiment includes:

[0076] Driving mechanism two 901;

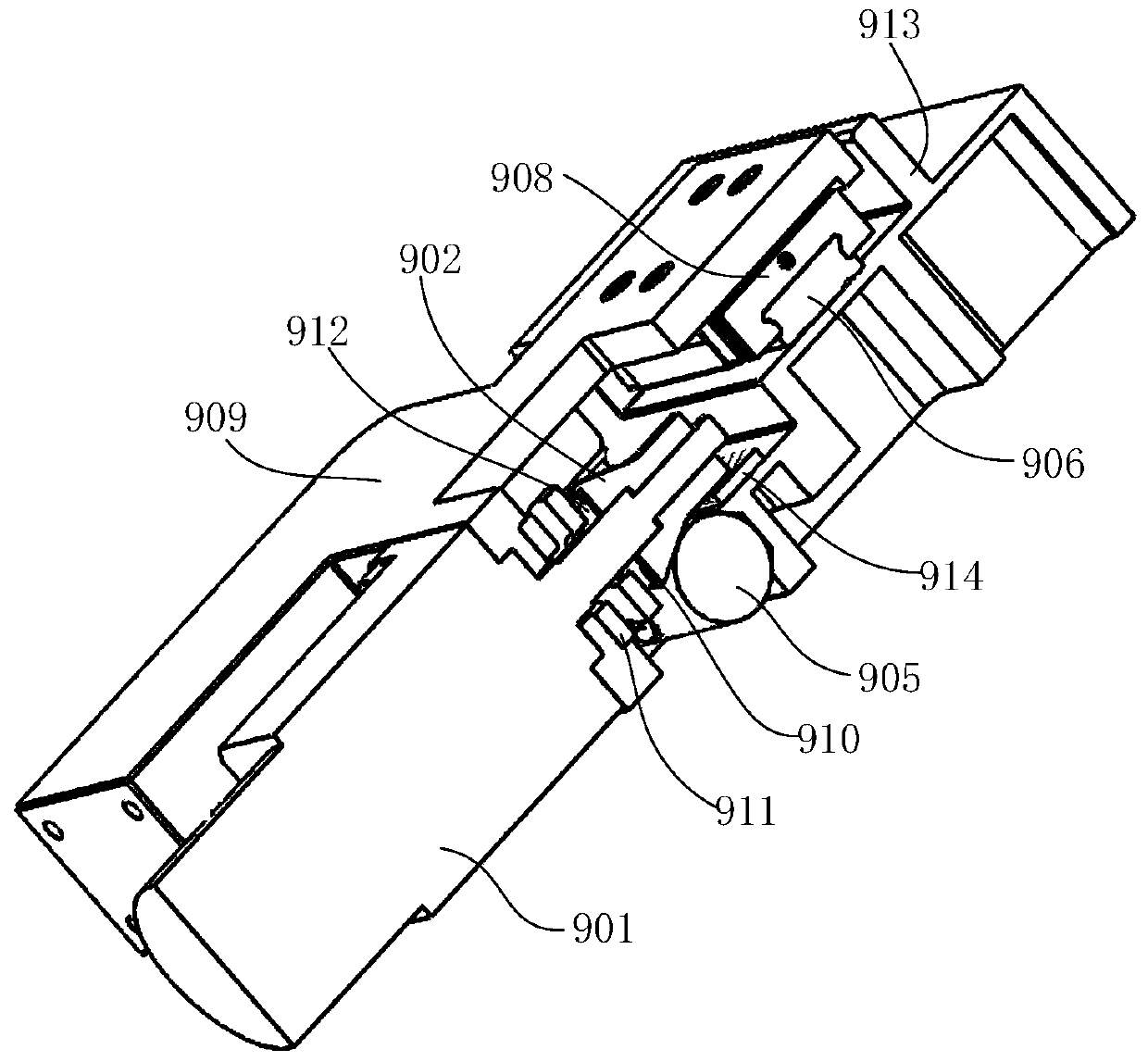

[0077] A conical friction wheel 902, the conical friction wheel 902 is spline-connected with the output shaft of the second driving mechanism 901;

[0078] A friction rod 905, the friction rod 905 is in friction fit with the conical friction wheel 902; the conical outer peripheral side of the conical friction wheel 902 abuts on the friction rod 905;

[0079] a guide rail 906, the guide rail 906 is arranged parallel to the friction bar 905;

[0080] A slider assembly 907, one end of the slider assembly 907 is slidably mounted on the guide rail 906, and the other end is fixedly connected to the casing of the second driving mechanism 901;

[0081] A load spring 910, the load spring 910 is sheathed on the output shaft of the drive mechanism 2 901, and sandwiched between the big end of the conical fric...

Embodiment 2

[0134] A material exposed platform outside the cabin of this embodiment, such as Figure 1-Figure 11 As shown, it includes a test box, an optical inspection module, an installation platform 800 and the driving device described in Embodiment 1, the test box is installed on the installation platform 800, and the exposed surface of the test box after opening faces the installation The surroundings of the platform 800 are arranged, and the guide rails are located near the peripheral side of the installation platform 800; the bottom of the support 701 is provided with a connecting plate 714 vertically arranged therewith, and the connecting plate 714 is connected to the second driving mechanism. , the optical inspection module 1 reciprocates in a direction perpendicular to the installation platform 800 under the drive of the steel wire rope 705, and reciprocates around the circumference of the installation platform 800 under the drive of the driving mechanism 2 , to inspect the expo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com