Conveying device used for steel product production

A conveying device and steel technology, applied in the field of conveying belts, can solve the problems of irregular shape of steel, scratching of guard plates, accumulation of steel and jamming conveying belts, etc., and achieve the effect of ensuring conveying efficiency, ensuring equipment operation and prolonging the service life of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

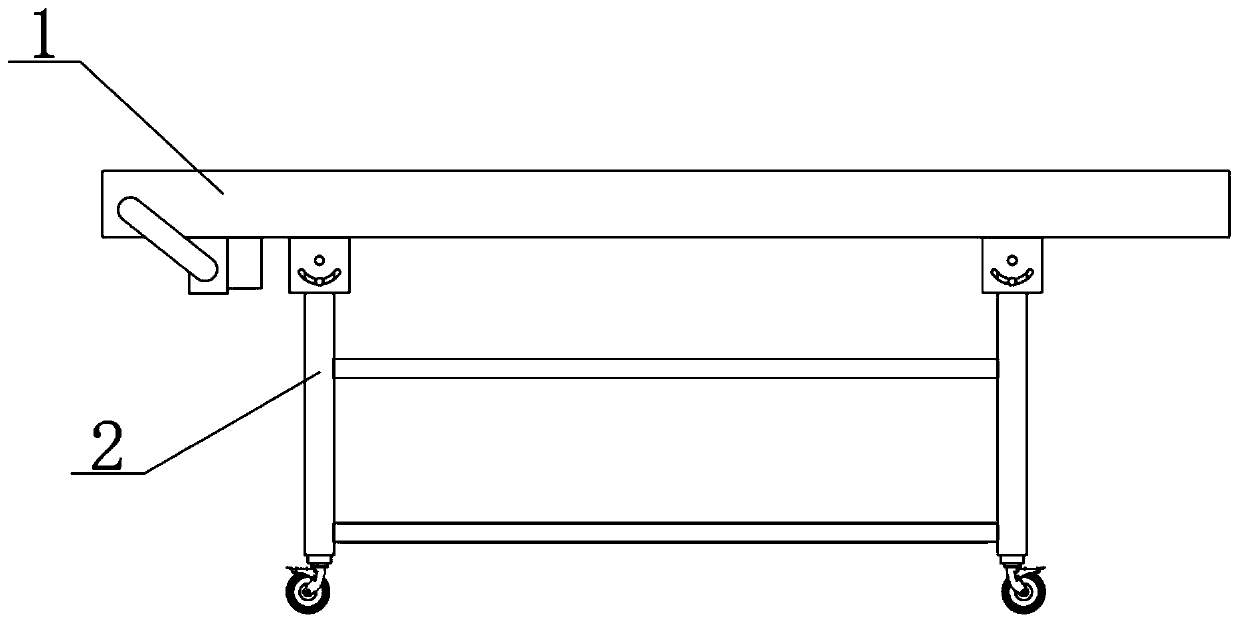

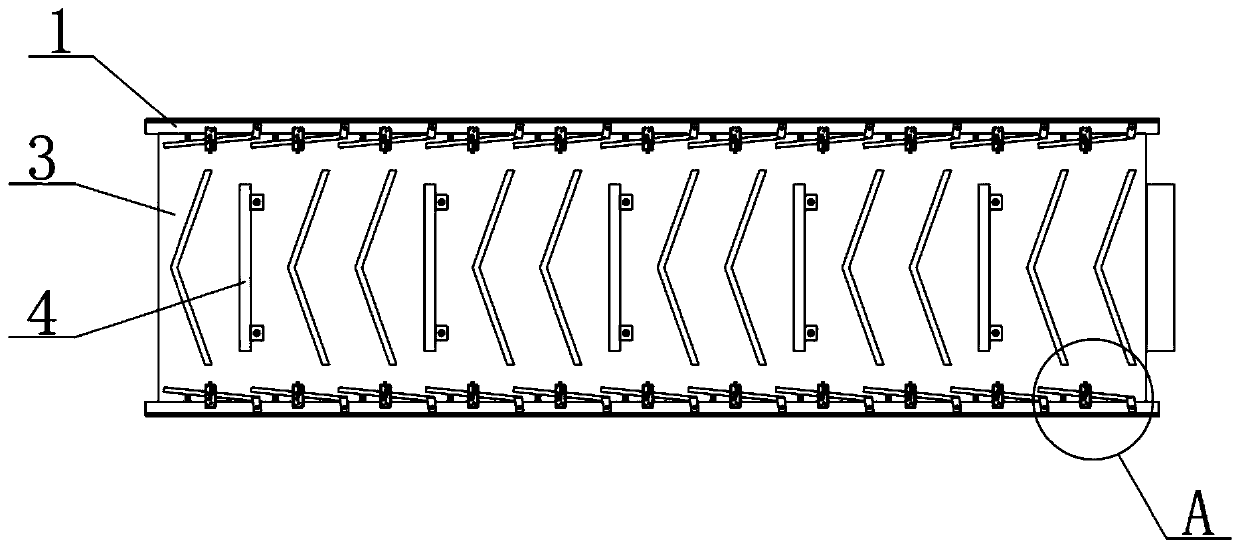

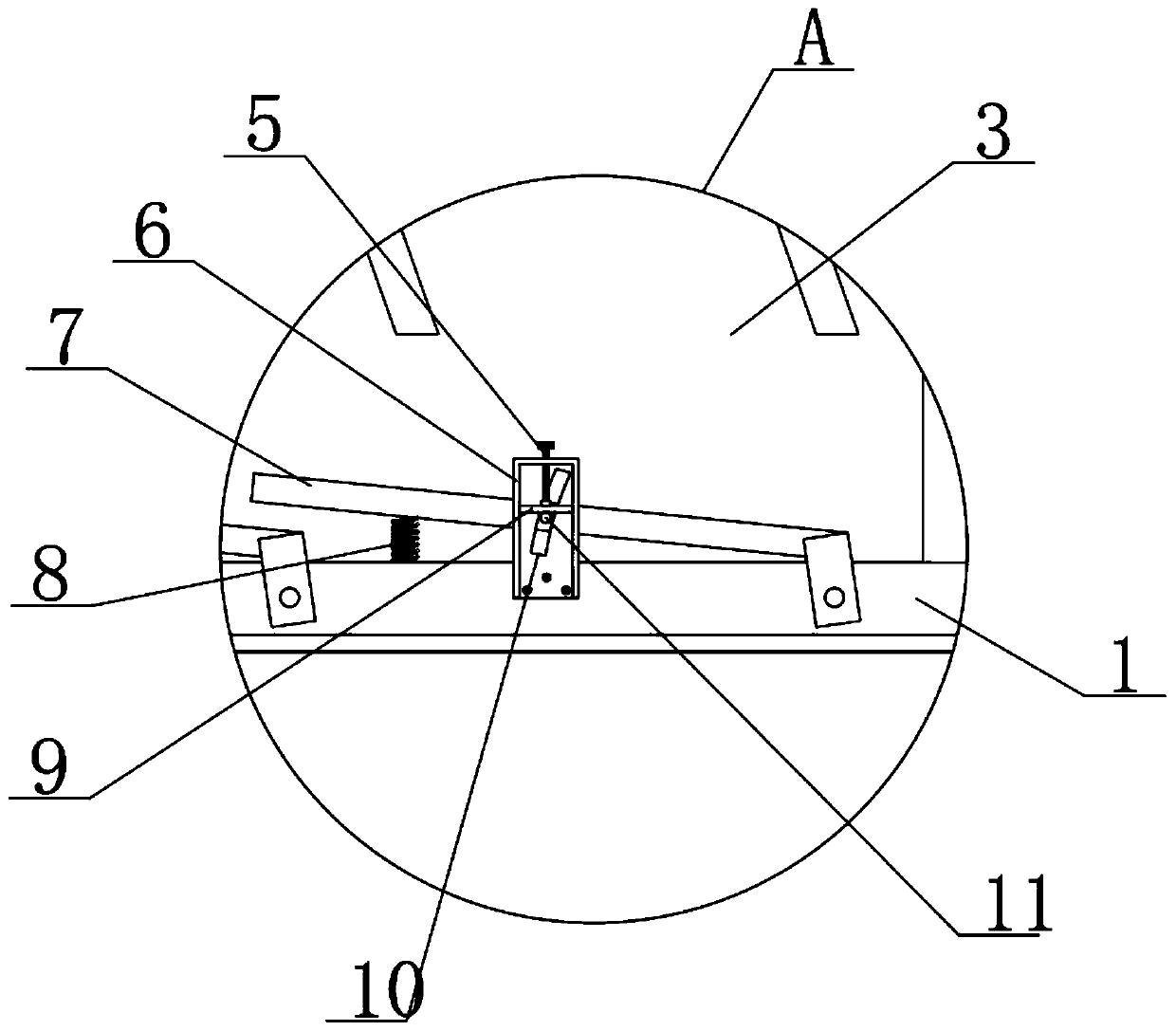

[0023] See Figure 1-Figure 5 , The present invention provides a technical solution: a conveying device for steel production, comprising a side plate 1, a support column 2, a conveyor belt body 3 and a connecting plate 13. The side plates 1 are symmetrically distributed on both sides of the conveyor belt body 3. , The lower end of the support column 2 is equipped with a universal wheel, the upper surface of the side plate 1 is installed with a baffle 7 through the connecting block and the rotating shaft, the lower end of the baffle 7 is in clearance fit with the upper surface of the conveyor belt 3, the baffle 7 A return spring 8 is fixedly connected between the free end of the member and the inner surface of the side plate 1, the upper surface of the baffle 7 is welded and fixed with a fixing rod 11, and the upper surface of the side plate 1 is fixed with a sliding box 6 by screws. The inner bottom surface of 6 is provided with a sliding groove 10, the upper end of the fixed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com