Yarn beating device for rope production

A kind of rope and consistent technology, applied in the field of yarn beating device for rope production, can solve the problems of single function and low take-up efficiency, and achieve the effect of high take-up efficiency, stable structure and function, and tight take-up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

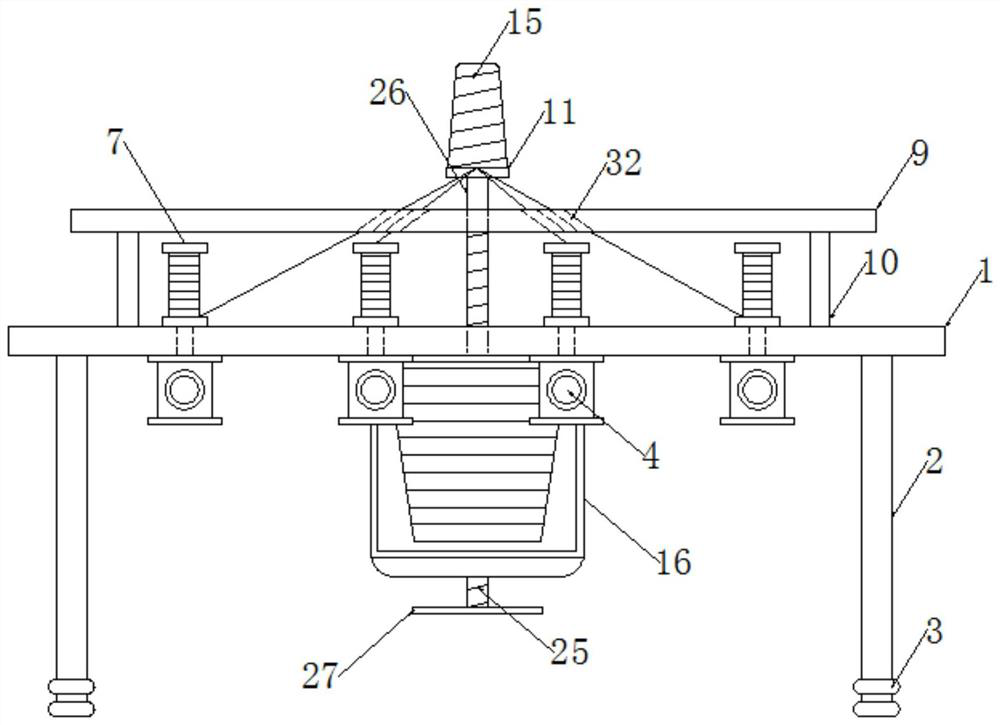

[0025] like Figure 1-10 As shown, this specific embodiment adopts the following technical solutions:

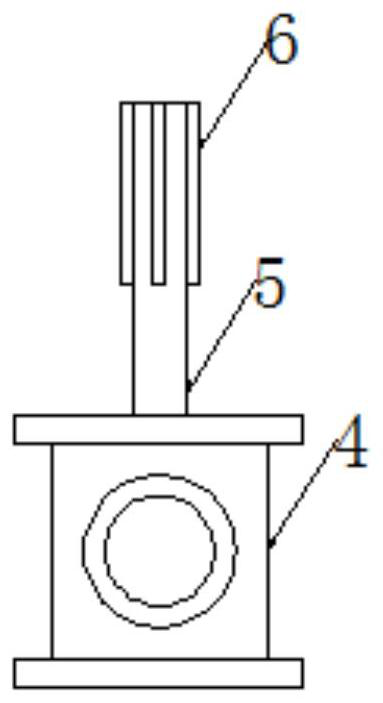

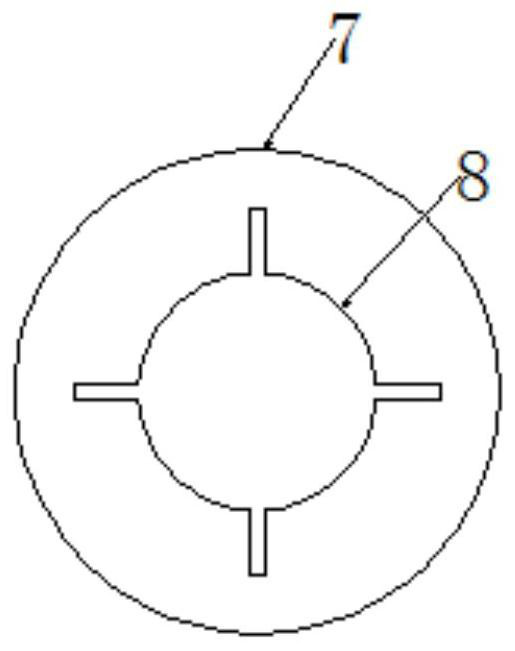

[0026] A yarn beating device for rope production, comprising a workbench 1, the workbench 1 is arranged in a disc shape, and four support columns 2 are fixedly installed on the lower end surface of the workbench 1, and the four support columns 2 have specifications. Consistent and arranged in a rectangular array with respect to the lower end surface of the workbench 1, the lower end surfaces of the four support columns 2 are fixedly installed with legs 3, the four legs 3 have the same specifications, and the lower end surface of the workbench 1 is fixedly installed with a number of shafts Seat 4, several of the shaft seats 4 have the same specifications, and are distributed in an equidistant circle with respect to the center position of the lower end face of the worktable 1. The upper ends of several of the shaft seats 4 are rotatably installed with shaft rods 5, and several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com