Carrying and loading mechanism for increased boom and arm travel and arm drive force

A loading mechanism and driving force technology, applied in mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc., can solve the problem of insufficient handling force, short loading stroke, insufficient driving force and lifting force, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

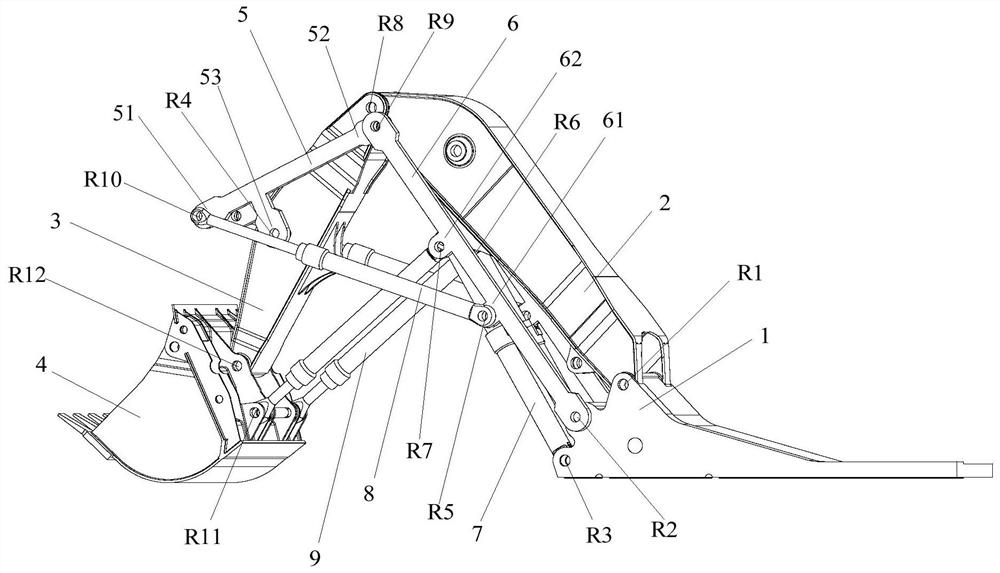

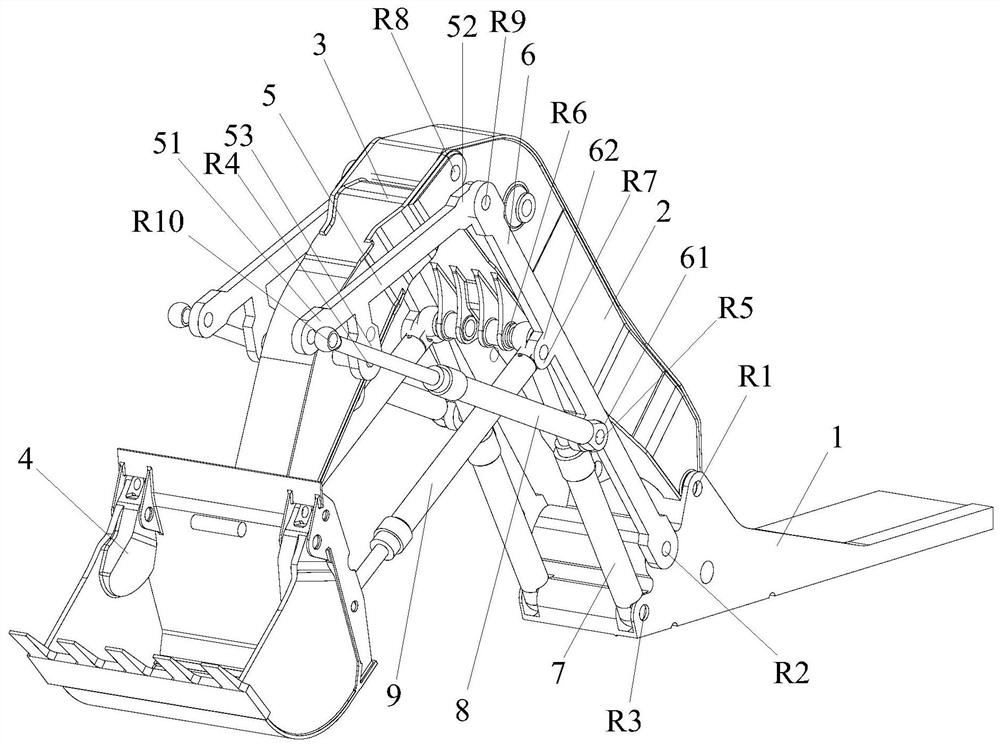

[0020] See figure 1 and figure 2 , an embodiment of the present invention provides a transporting and loading mechanism for improving the stroke of the boom and the stick and the driving force of the stick, including a frame 1, a boom 2, a stick 3, a terminal actuator 4, and a pair of powerful triangles 5 and a pair of four sub-rods 6.

[0021] The lower end of the boom 2 is hinged to the frame 1 through the hinge R1, the upper end of the boom 2 is hinged to one end of the stick 3 through the hinge R8, and the other end of the stick 3 is connected to the terminal through the hinge R12. The upper part of the mechanism 4 (the terminal actuator in this embodiment is a bucket) is hinged, and the middle part of the boom 2 is connected to one end of a pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com