Waterproof agent brushing treatment process for building decoration dry-hanging stone before construction

A technology of dry hanging stone and processing technology, applied in stone processing tools, stone processing equipment, coatings and other directions, can solve the problems of leakage, unevenness and addition of waterproofing agents, and prevent leakage and uneven application. Guaranteed application quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

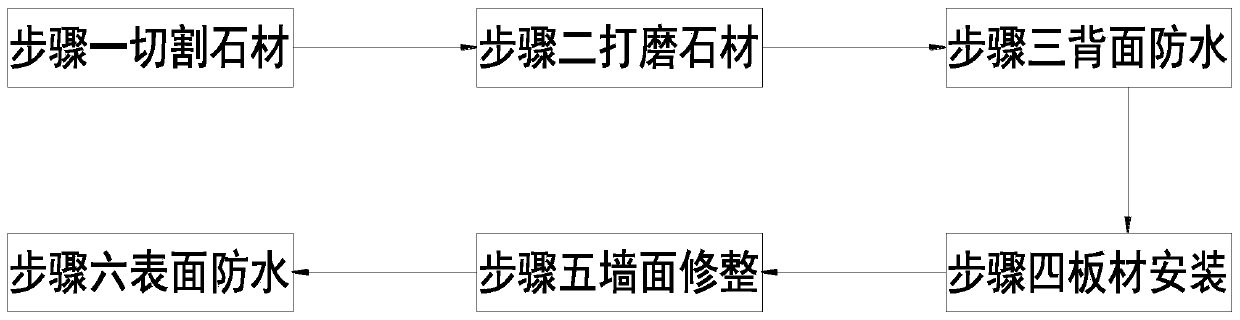

[0039] Such as Figure 1 to Figure 9 As shown, a water-repellent coating treatment process before construction of decorative dry hanging stone mainly includes the following steps:

[0040] Step 1: Cutting the stone: According to specific needs, use a stone cutting machine to cut the stone, and make the edges and corners of the cut stone straight and not chipped;

[0041] Step 2: Polish the stone: Use a stone grinder to polish the stone edges and corners after the above-mentioned step one treatment, so that the stone edges and corners are smooth and there is no breakage;

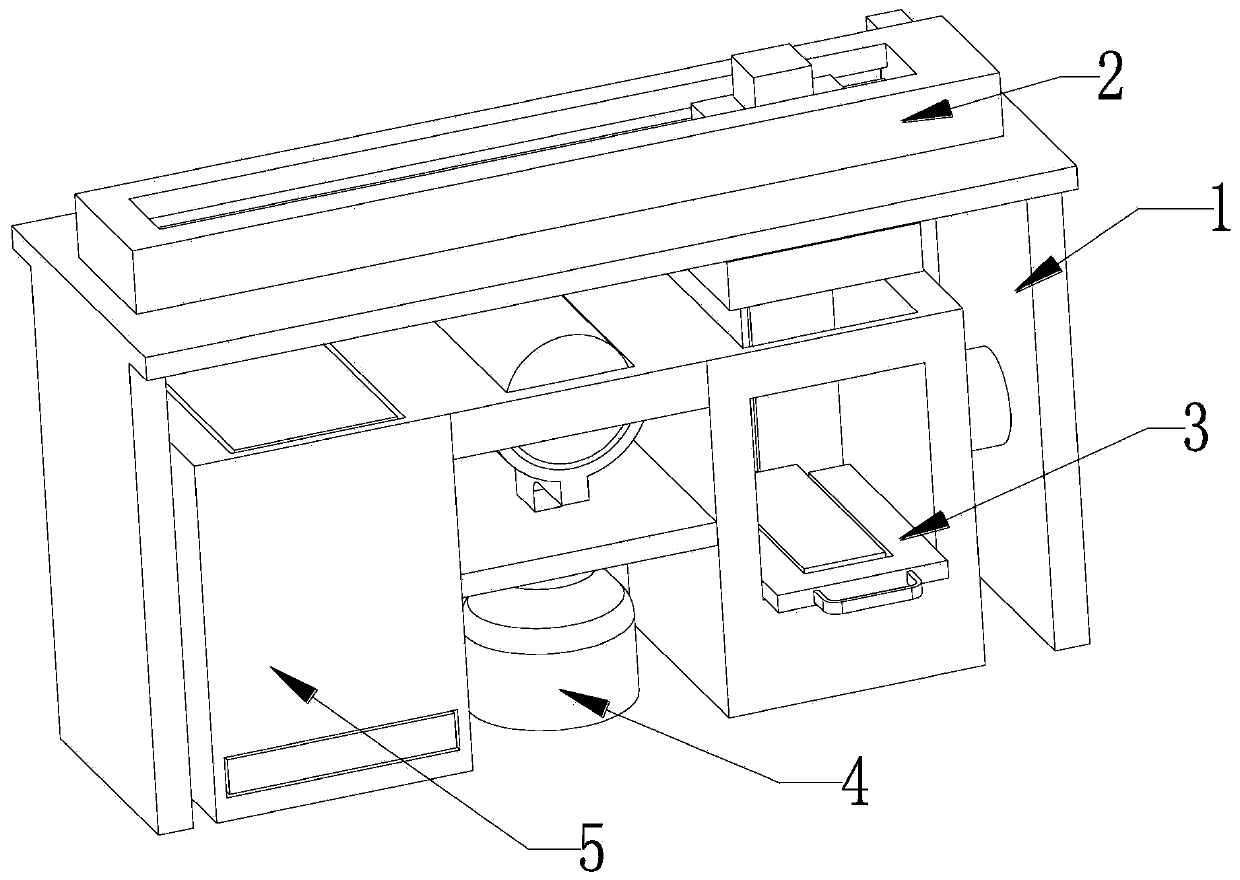

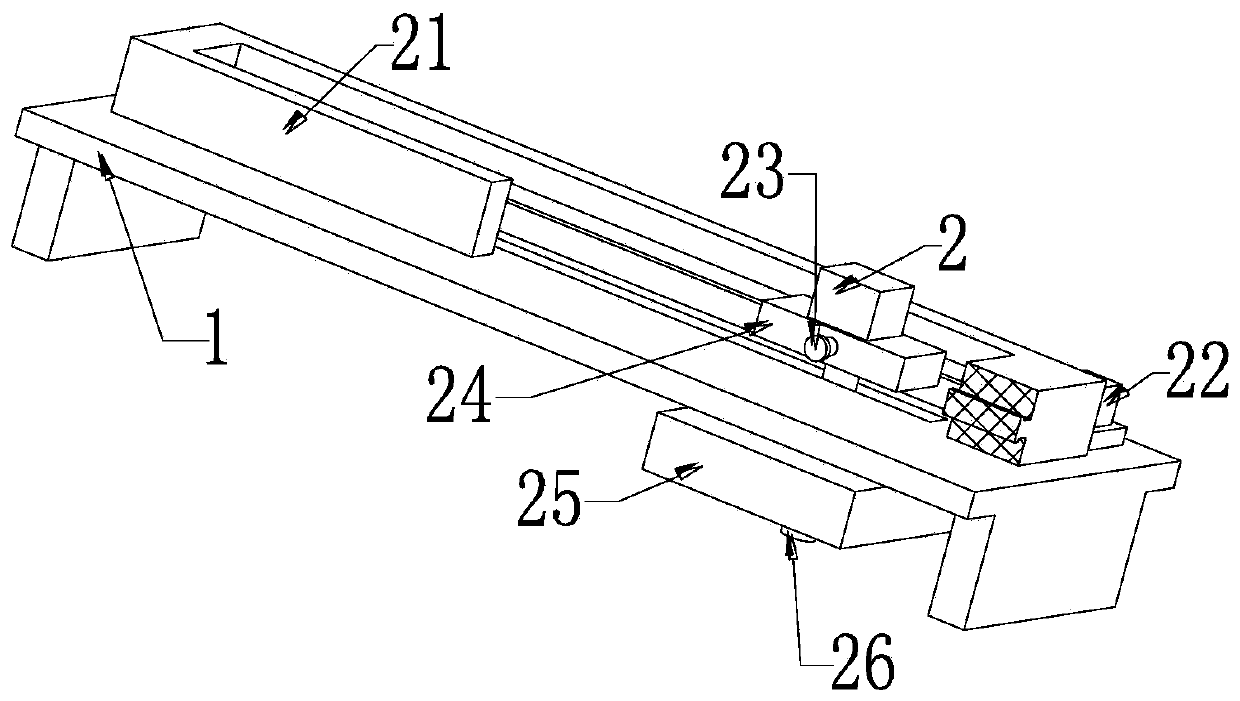

[0042] Step three, backside waterproofing: use a waterproofing agent brushing device to apply a waterproofing agent to the back of the stone that has been processed in step two to enhance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com