A pipe precision butt joint, quick lock joint

A technology for locking joints and pipes, applied in the direction of pipes/pipe joints/pipe fittings, flange connections, passing components, etc. Manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

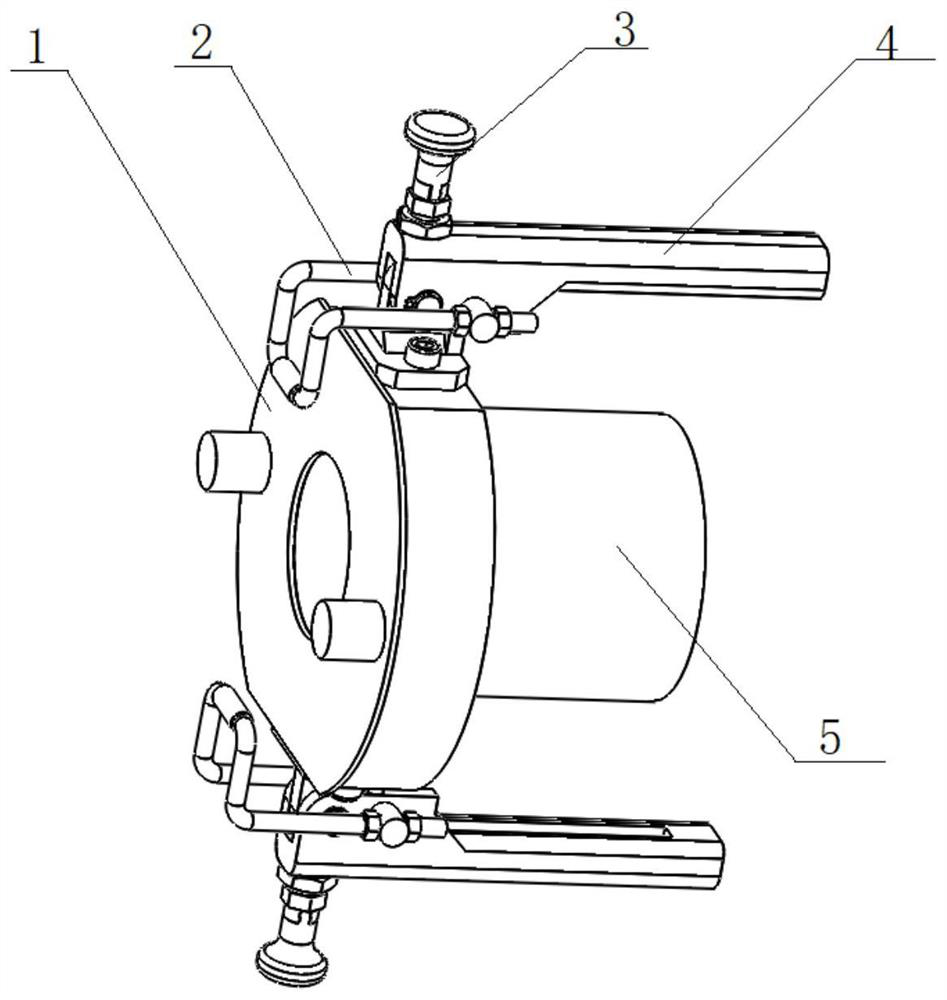

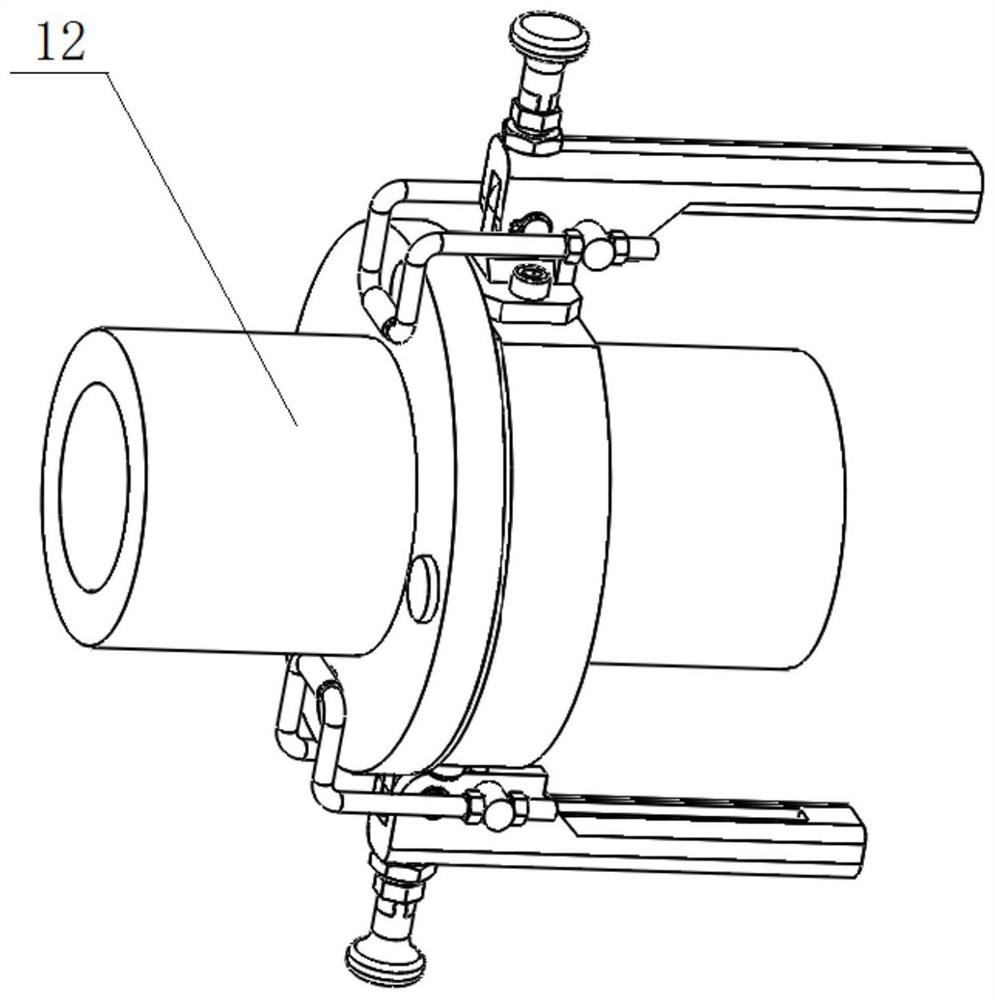

[0023] This embodiment provides a precise butt joint of pipelines and a fast locking joint, which includes a stepped flange 5, a sealing gasket 1 and two pull-type locking components.

[0024] Such as figure 1 As shown, two cylindrical pins protrude from the large-diameter end surface of the stepped flange 5, and the gasket 1 is set on the cylindrical pin, and is in contact with the large-diameter end surface of the stepped flange 5, and the small-diameter end of the stepped flange 5 is used for It is fixedly connected with the pipeline; two pull-type locking components are symmetrically fixed on the platform of the outer circumference of the large-diameter end of the stepped flange 5 along the axis of the pipeline.

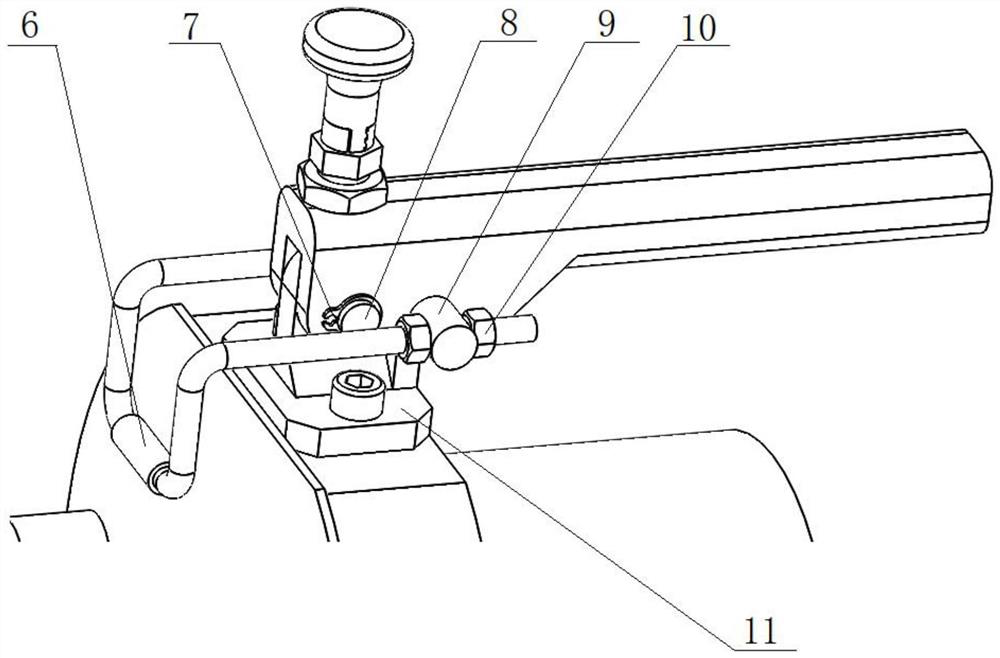

[0025] Such as figure 1 , figure 2 As shown, the buckle locking assembly includes a base 11 , a pop-up stop pin 3 , a handle 4 , a buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com