Method for accurately obtaining reactivity feedback changes in transient process of fast neutron reactor

A transient process and reactive technology, applied in reactors, nuclear reactor monitoring, nuclear engineering, etc., can solve problems such as reactor component bending, rod position reduction, single reactivity feedback coefficient and equivalent temperature, etc., to ensure high precision , Guarantee the effect of high efficiency and complete responsive feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

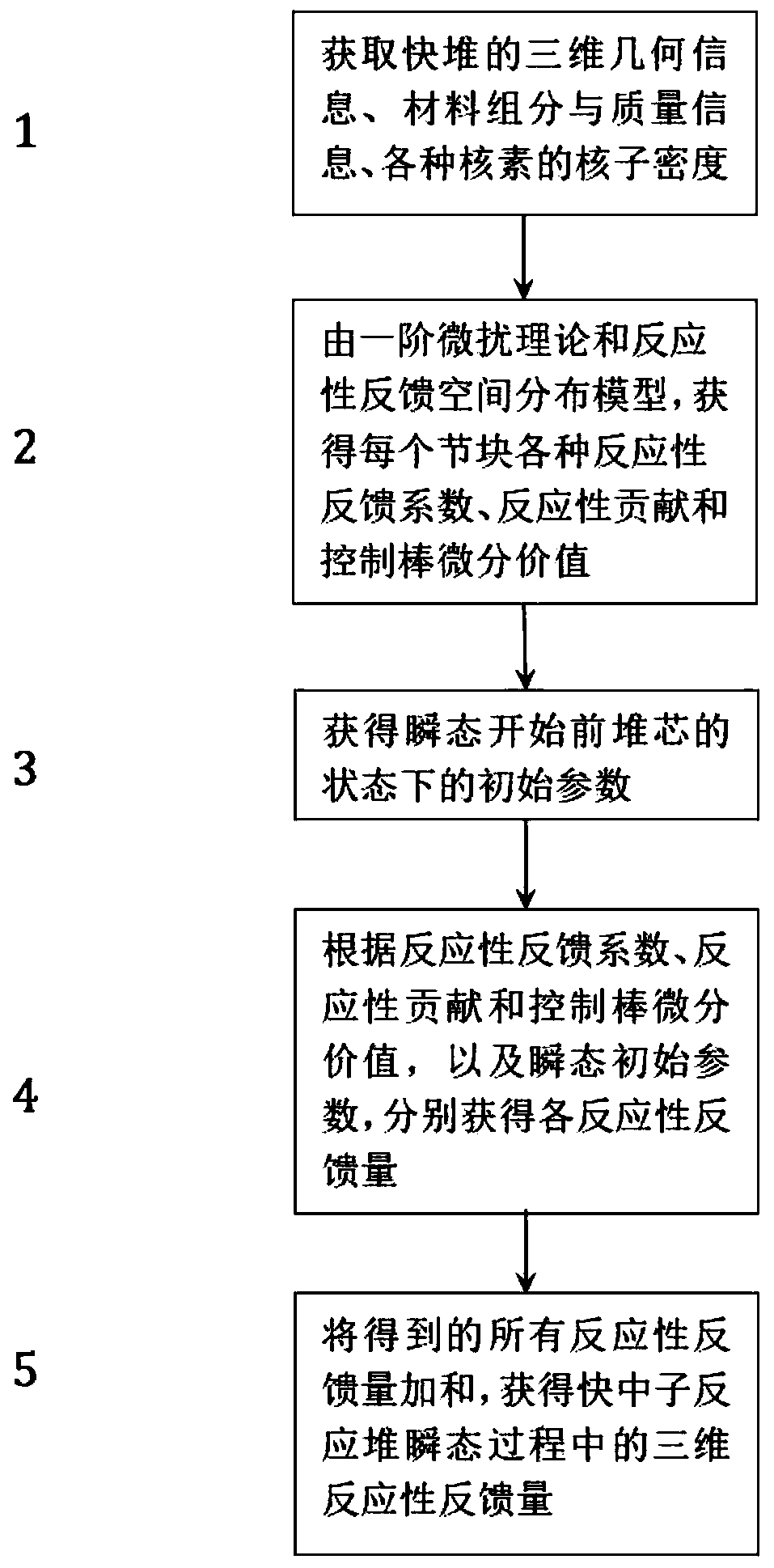

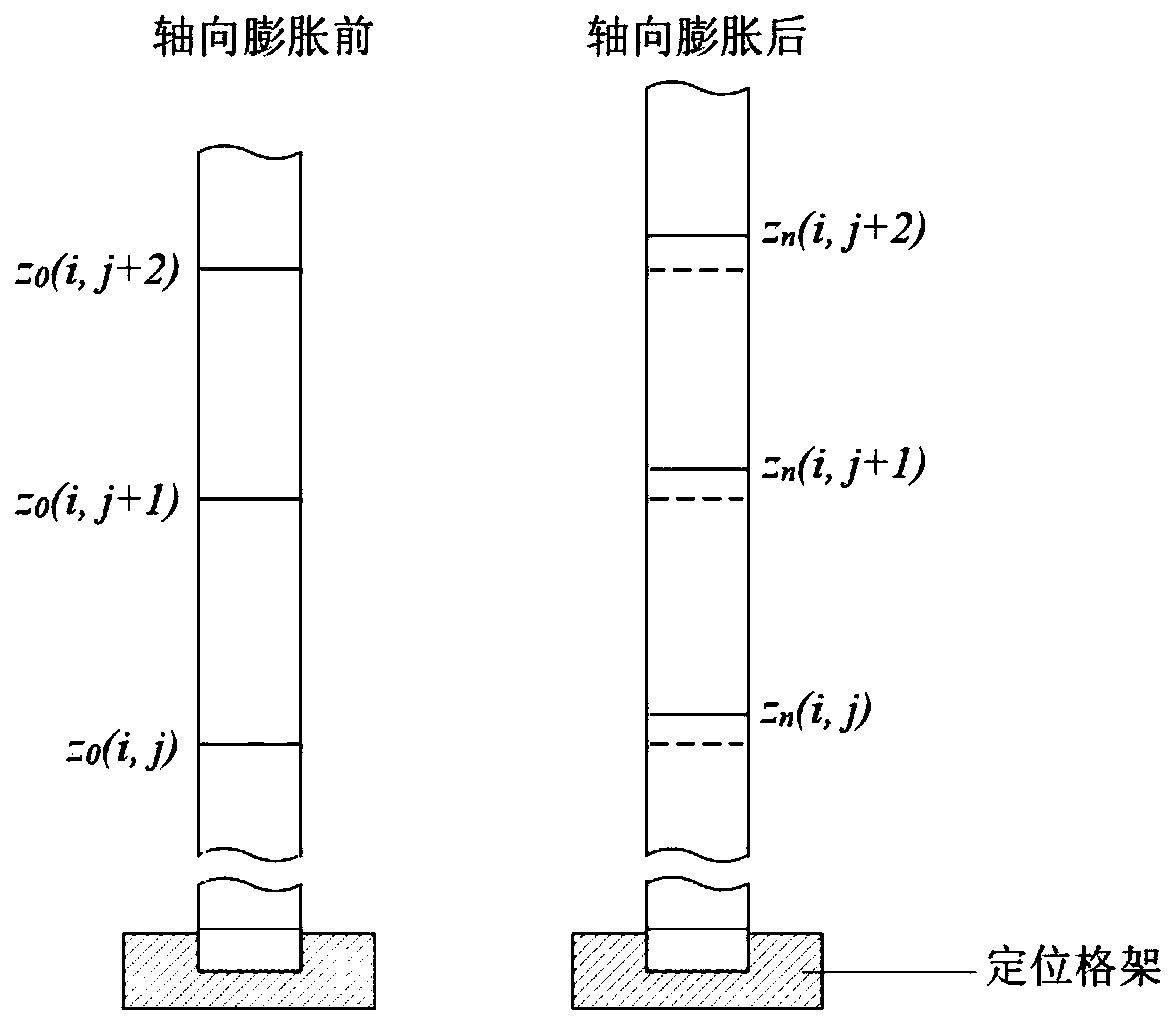

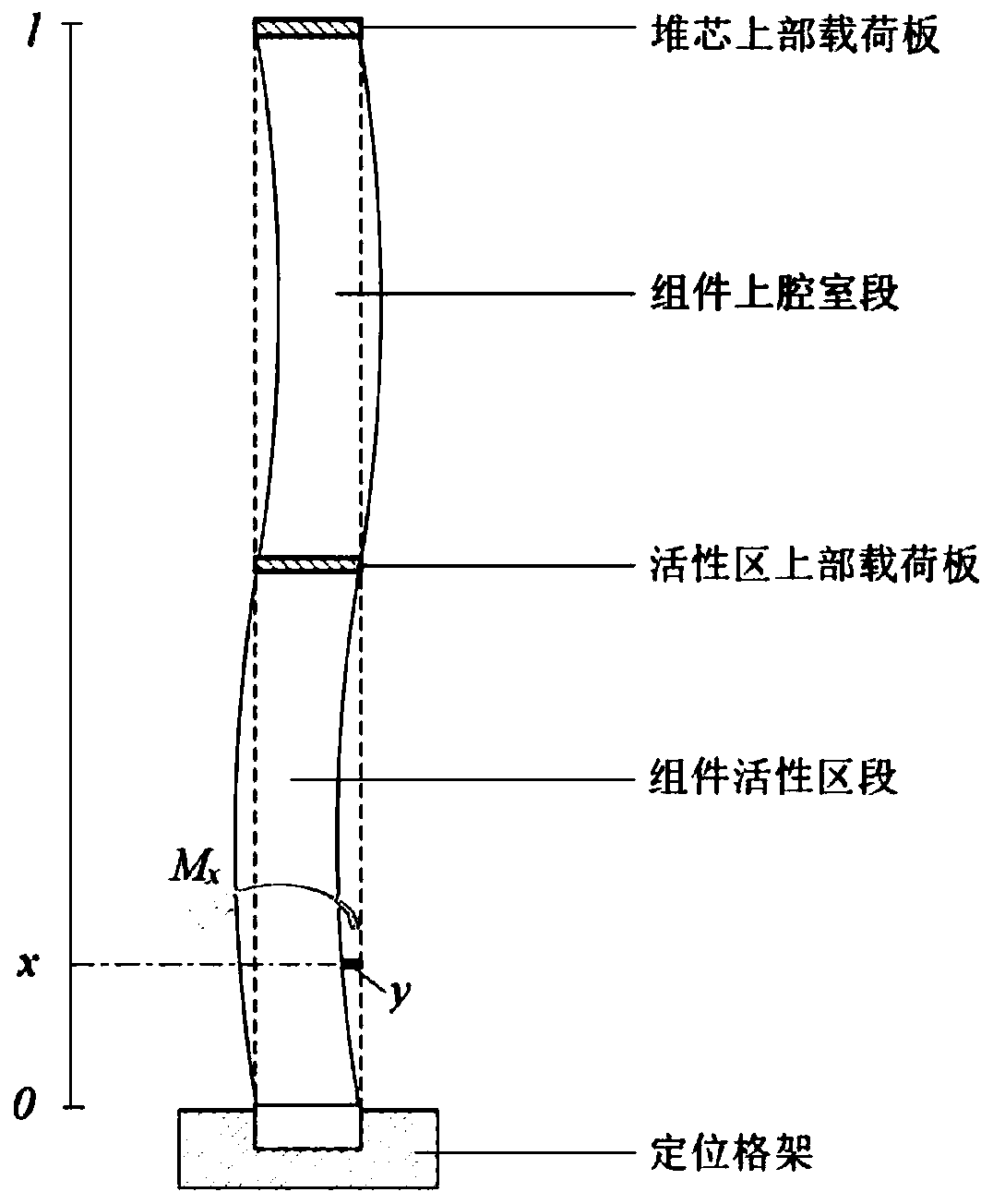

[0108] The invention considers the spatial distribution of reactivity feedback, uses the first-order perturbation theory to finely consider the reactivity feedback changes of each node of the fast pair assembly, and calculates the accurate fuel temperature reactivity feedback and coolant density reactivity feedback of each node; proposes the reaction The concept of linear contribution, finely calculate the axial expansion reactivity feedback of each section of the fast reactor component; introduce the mechanical model, calculate the bending offset of the fast reactor component, and accurately calculate the bending reactivity feedback of each section of the component; introduce convective heat transfer The model, which takes into account the effect of the expansion of the control rod drive mechanism on the reactivity, calculates the reactivity fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com