Garbage sorting and winnowing system

A garbage sorting and winnowing technology, which is applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of slow sorting speed, and achieve the goal of improving sorting speed and improving sorting efficiency. Speed, the effect of increasing movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

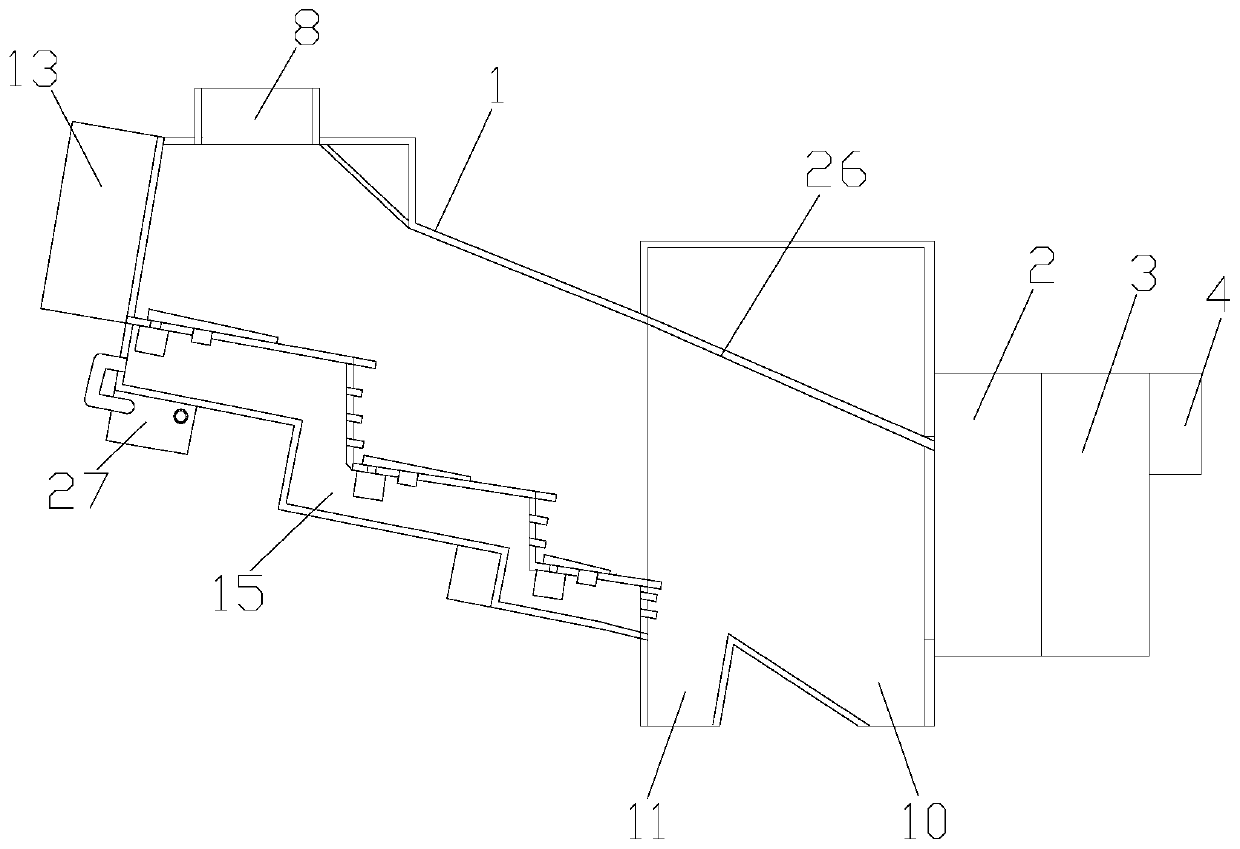

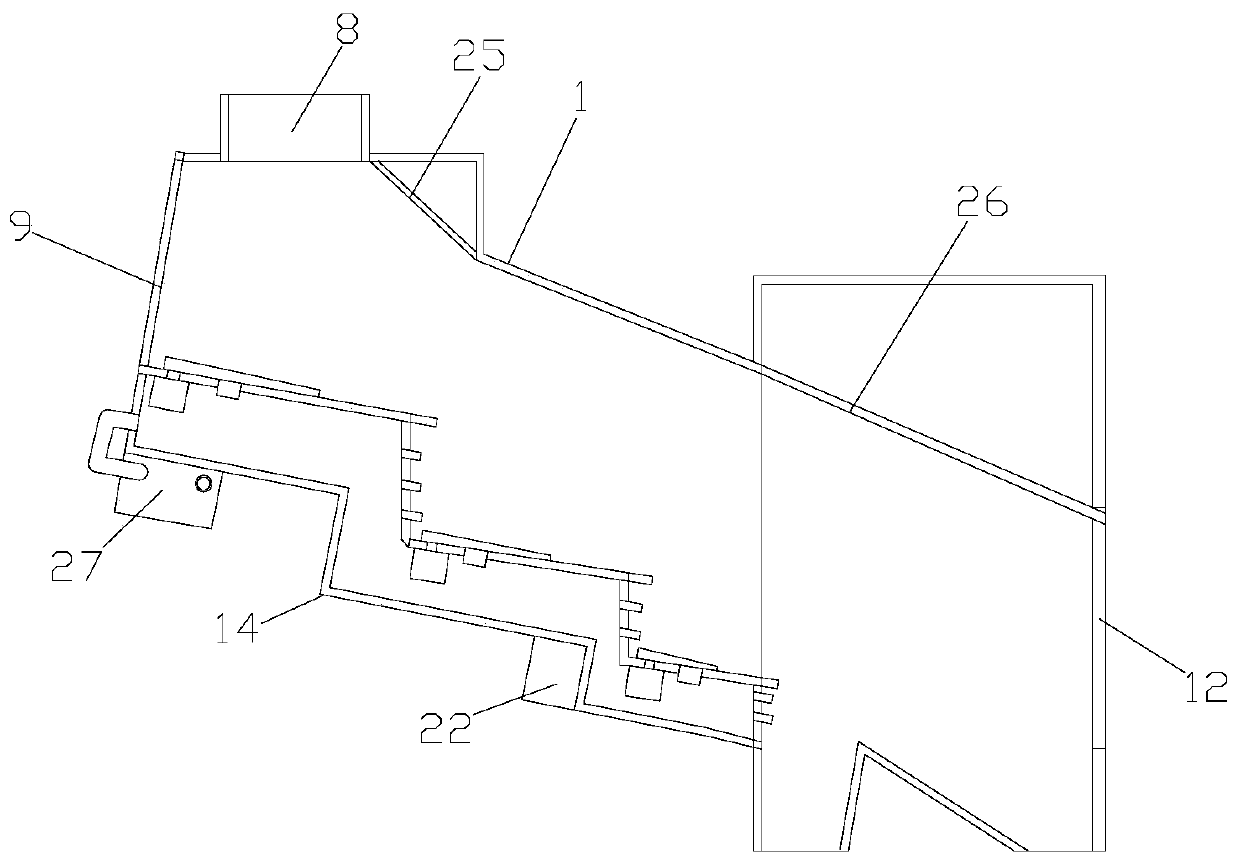

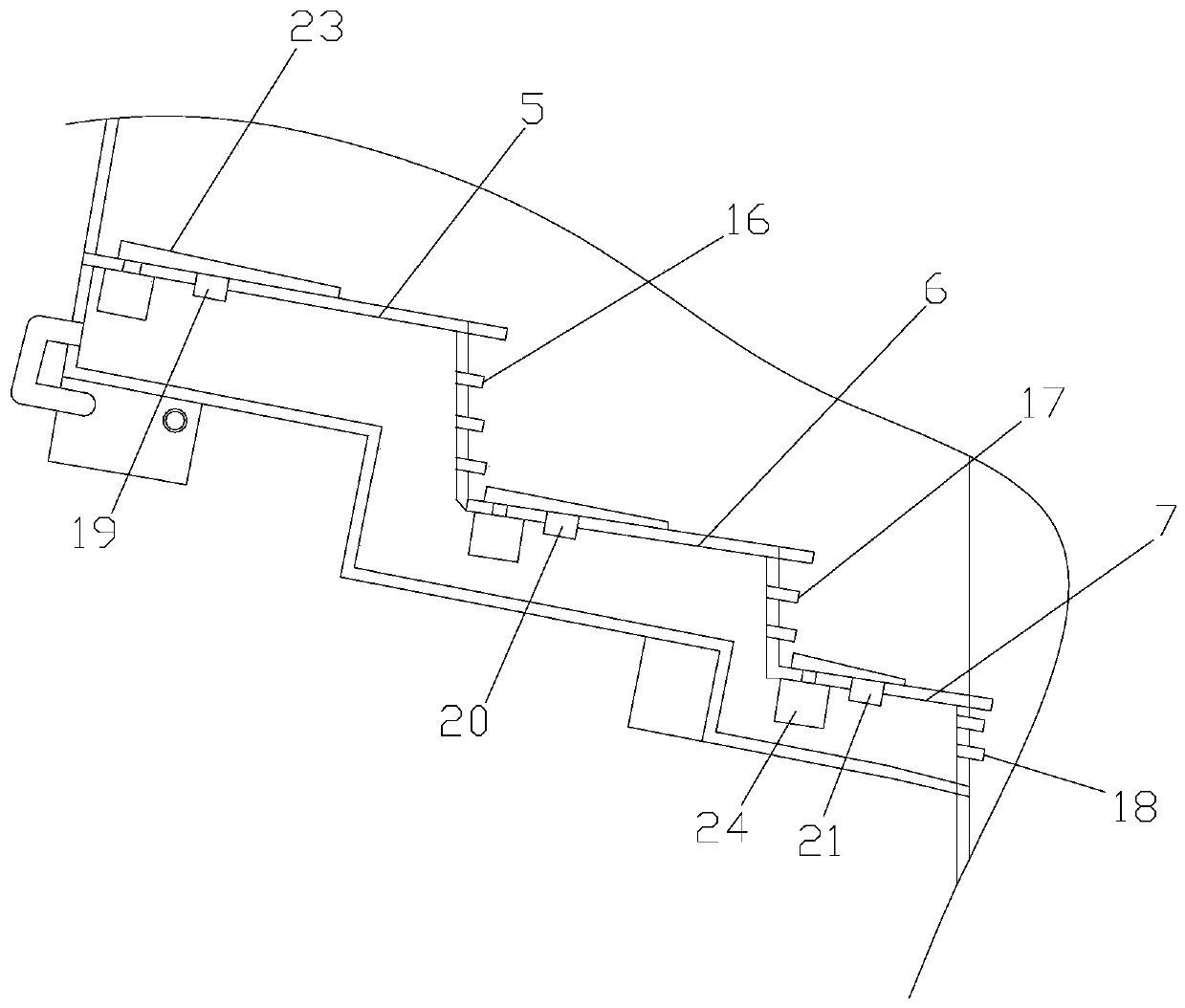

[0029] Such as Figure 1-3 As shown, a garbage classification winnowing system includes a garbage bin 1, a small and light material collector 2, a dust collector 3, and an induced draft fan 4. The garbage bin 1 is provided with a first inclined bottom plate 5 and a second inclined bottom plate 6 and the third inclined bottom plate 7, the first inclined bottom plate 5, the second inclined bottom plate 6 and the third inclined bottom plate 7 are distributed in a stepped manner, and the garbage bin 1 is provided with a feeding port 8, an air inlet 9, and light materials The outlet 10, the heavy material outlet 11 and the light material outlet 12, the feeding port 8 is located above the first inclined bottom plate 5, the air inlet 9 is provided with a blower 13 on one side, the 13 is inclined, and the first inclined The bottom plate 5, the second inclined bottom plate 6 and the third inclined bottom plate 7 are all in the same inclination as the blower 13, and the garbage bin 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com