Contact lens surface hydrophilic coating method

A contact lens, hydrophilic technology, used in glasses/goggles, optics, instruments, etc., can solve the problems of low oxygen permeability of glass materials, discomfort, easy to cause eye diseases, etc., to maintain clarity and good comfort. , good hydrophilic effect

Active Publication Date: 2020-04-24

UNICON OPTICAL

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Contact lenses have been developed for many years. At first, scientists held the idea of wearing the lenses directly on the eyes and developed cont

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

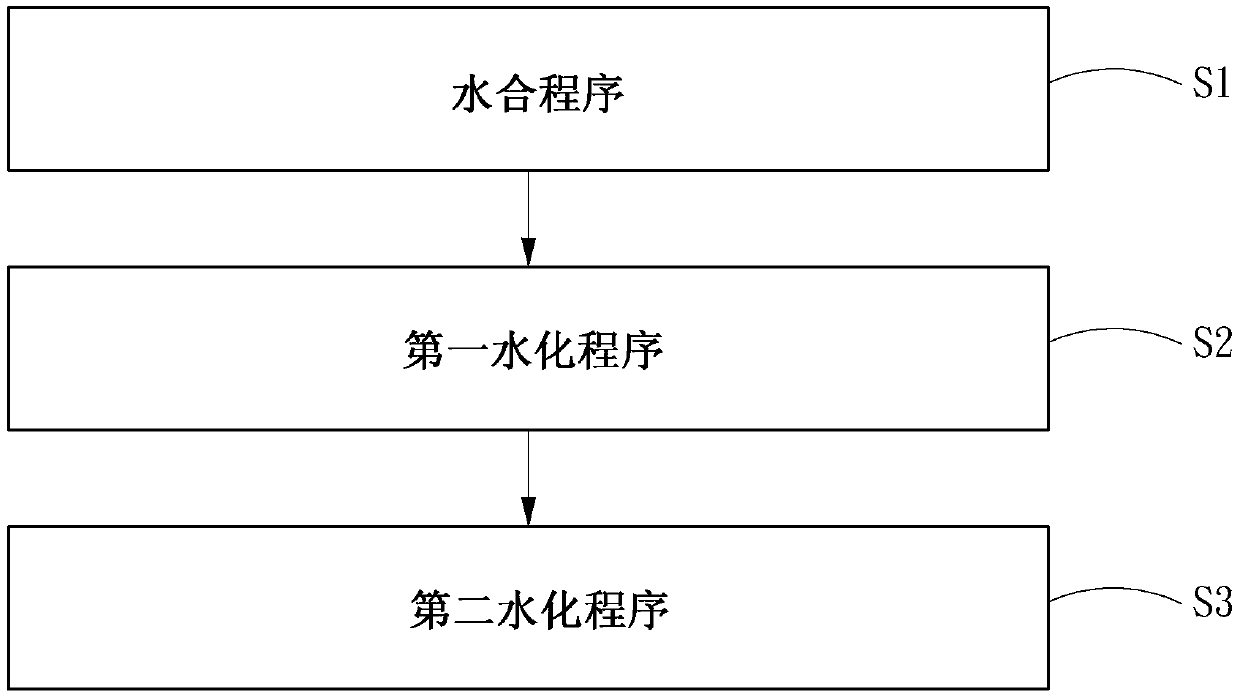

The invention provides a contact lens surface hydrophilic coating method. The method comprises the steps: firstly, performing a hydration process to make a non-hydrated polymer form a hydrated polymer, and sequentially making the hydrated polymer contact with a first solution containing a high-molecular compound and a second solution containing a high-molecular compound at a specific temperature between 50 DEG C and 70 DEG C to complete the first hydration process and the second hydration process. According to contact lenses obtained according to the steps, the contact angle ranges from 30 degrees to 65 degrees, protein and lipid are not prone to being deposited on the surfaces of the contact lenses, and good comfort is provided for a user when the user wears the contact lenses.

Description

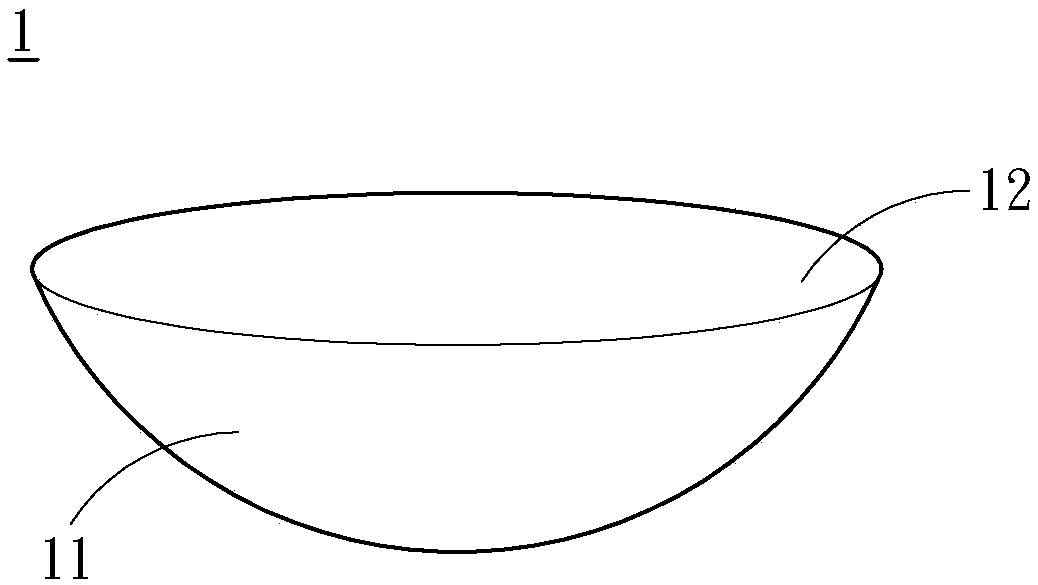

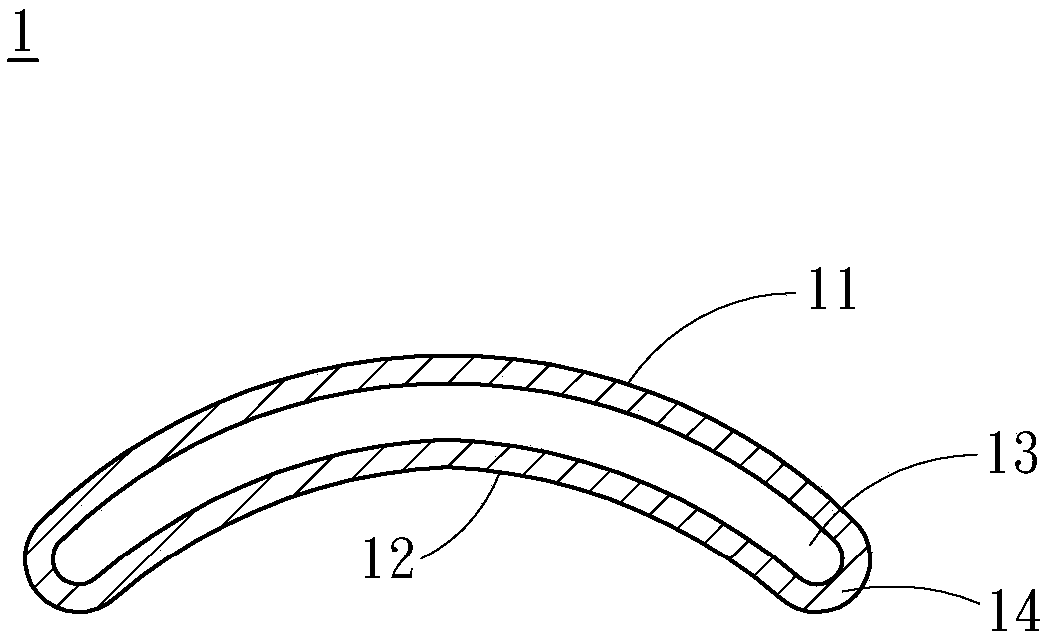

technical field [0001] The invention relates to a method for manufacturing a medical device for correcting vision, in particular to a method for coating a surface of a contact lens with a hydrophilic coating. Background technique [0002] Contact lenses have been developed for many years. At first, scientists held the idea of wearing the lenses directly on the eyes and developed contact lenses made of glass. However, not only are they uncomfortable, but the low oxygen permeability of the glass material can easily cause eye diseases. Later, other materials were adopted successively, from the earliest polymethyl methacrylate (PMMA) material to the modern rigid gas permeable contact lens (RGP) material rigid contact lens, and polymethacrylate hydroxyl Soft contact lenses made of ethyl ester (HEMA) or hydrogel, etc. [0003] Contact lenses do not have the hindrance of traditional spectacle frames, do not affect the wearer's appearance, and do not have the risk of shattering l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29D11/00G02B1/10G02C7/04

CPCB29D11/00067B29D11/00048G02B1/10G02C7/049

Inventor 林纪宇萧旭贵林庭萱

Owner UNICON OPTICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com