Throat pipe brick and glass substrate manufacturing device

A throat and brick-based technology, applied in the field of TFT-LCD glass substrate manufacturing, can solve the problems of clarification and homogenization, uneven cooling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

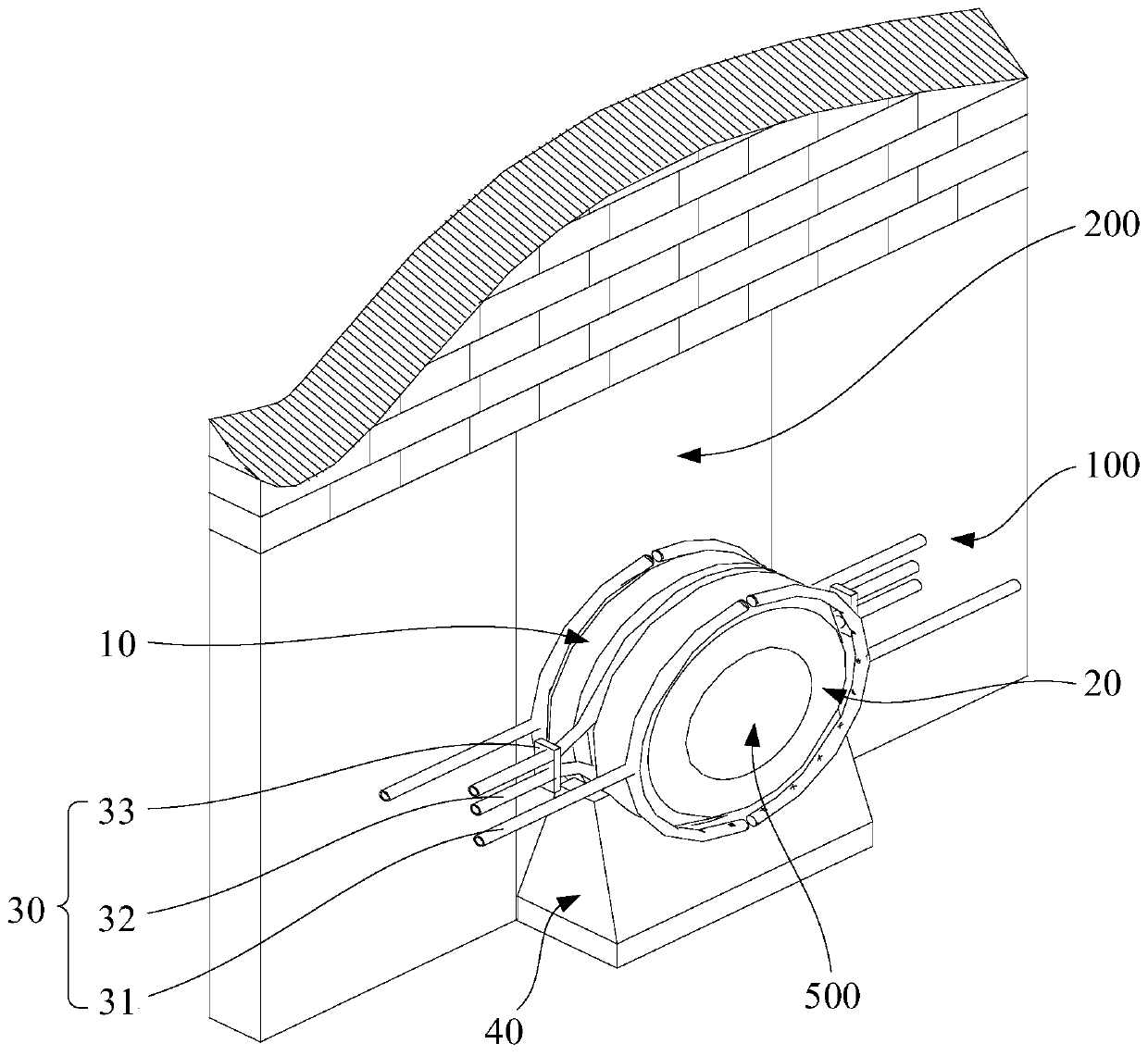

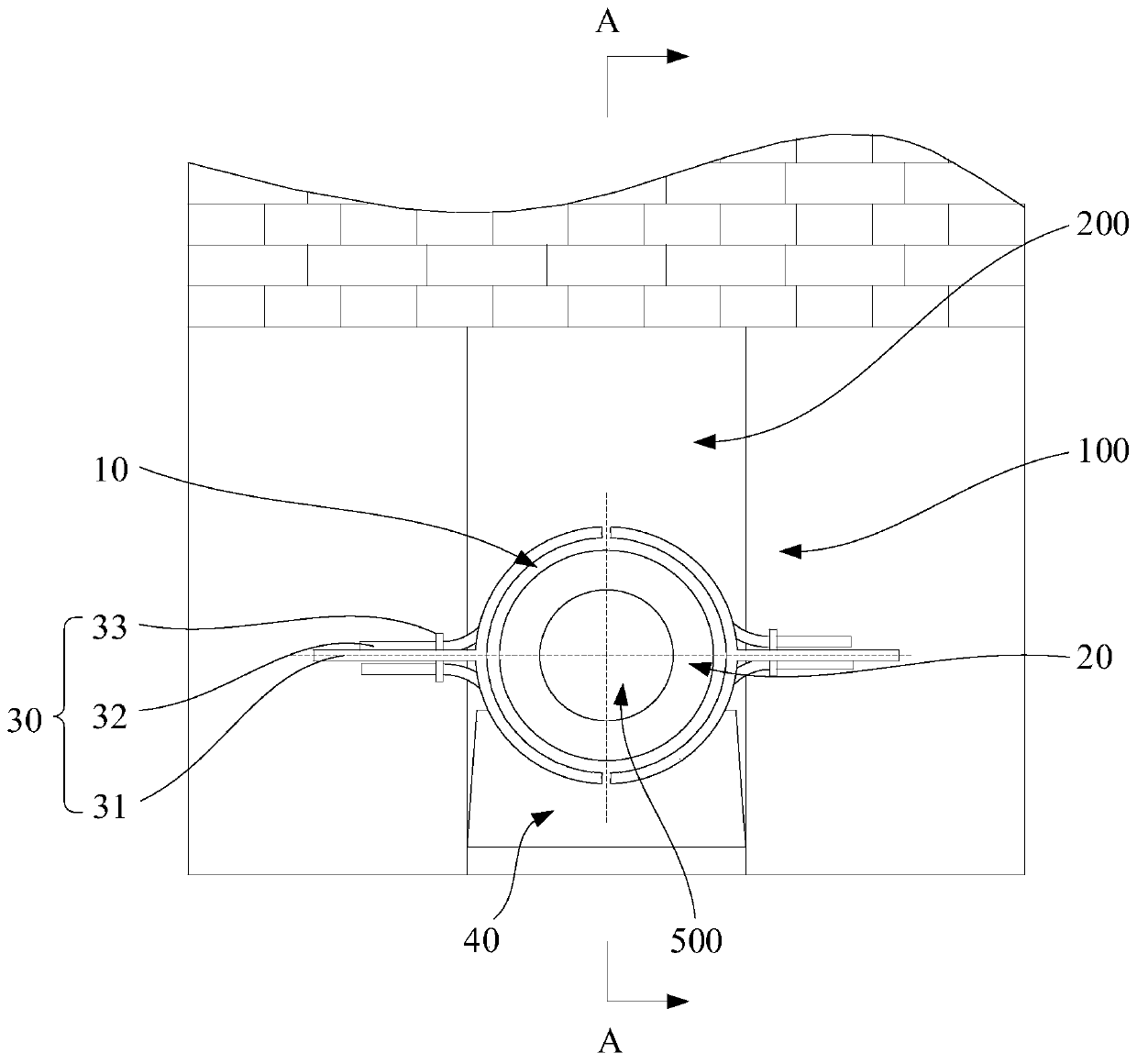

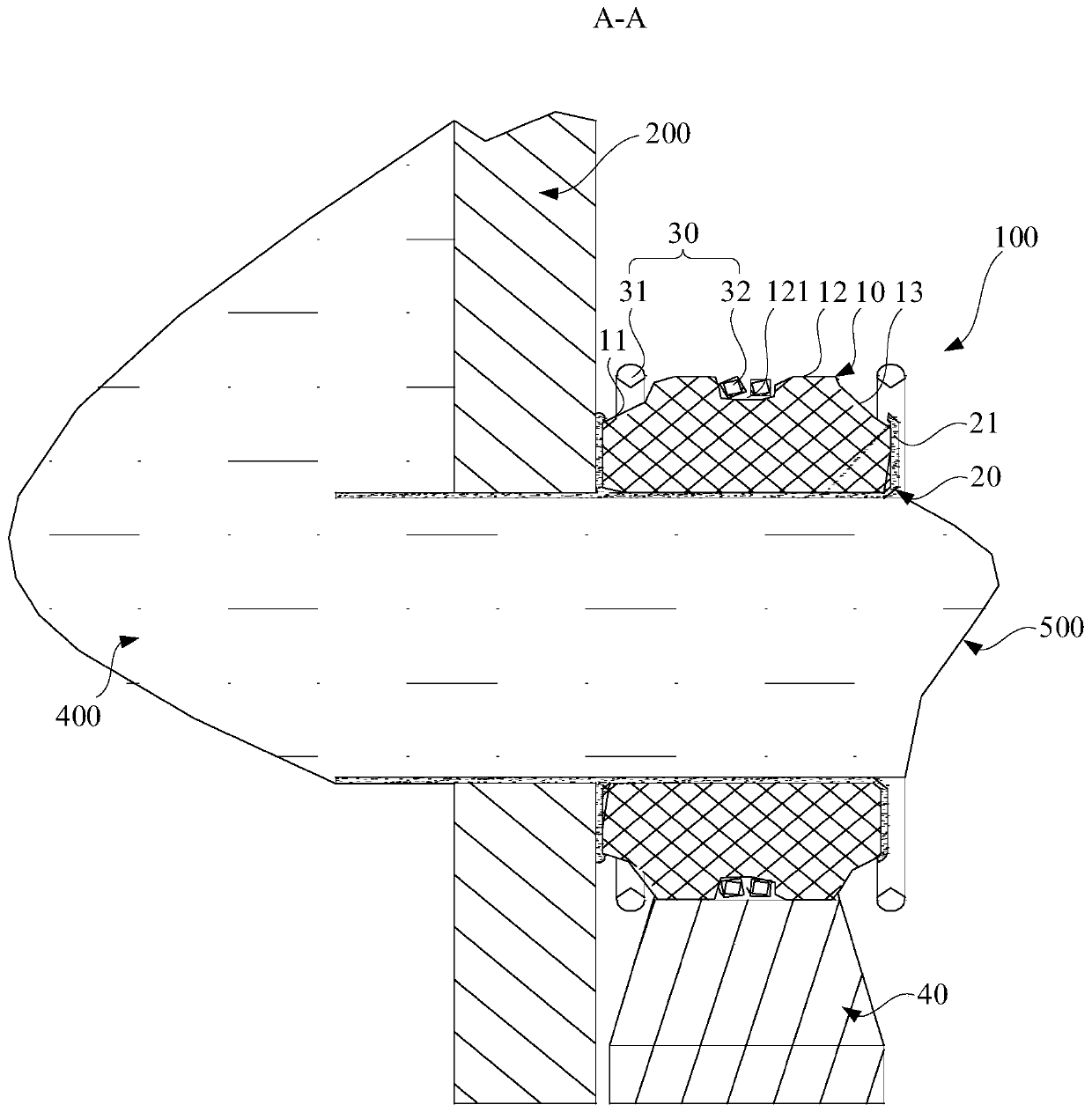

[0038] Please refer to Figure 1 to Figure 3, the present embodiment provides a throat block 100, including a throat block body 10, a throat body 20, and a cooling assembly 30. Both the throat block body 10 and the throat body 20 have a hollow cylindrical structure, and the throat body 20 is set Inside the throat block body 10, and the two ends of the throat block body 20 respectively extend outwards along the radial direction with ring-shaped flanges 21, and the two flanges 21 cover the two sides of the throat block body 10 respectively. At the end, the throat brick body 10 is used to connect the pool wall brick 200 on the rear wall of the pool furnace and the platinum channel inlet, and the cooling assembly 30 is sleeved on the outer wall of the throat brick body 10 for cooling the throat brick body 10 . The throat block 100 can uniformly cool the molten glass inside the throat block 100 along the circumferential direction.

[0039] It should be noted that, firstly, the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com