Laser surface zirconium infiltration method for improving surface hardness and wear resistance of titanium alloy

A surface hardness, titanium alloy technology, applied in metal material coating process, coating and other directions, can solve problems such as lack of effective means, and achieve the effect of improving surface hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

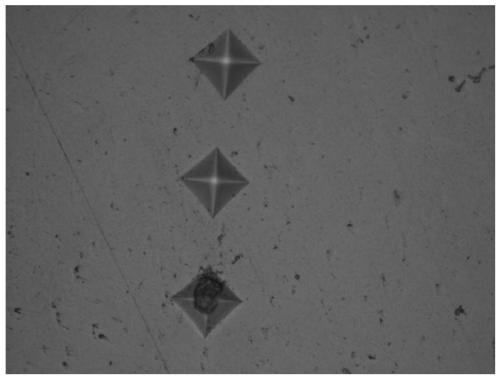

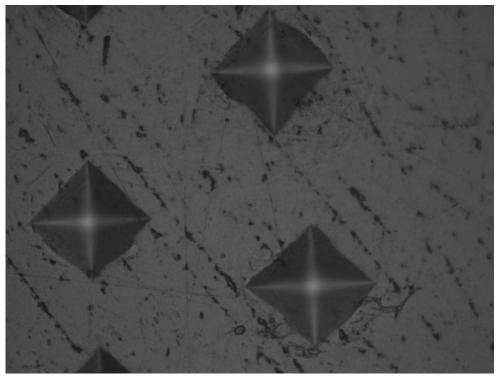

Image

Examples

Embodiment 1

[0019] A laser surface zirconium infiltration method for improving the surface hardness and wear resistance of titanium alloys comprises the following steps:

[0020] Step 1: Set the laser to the continuous laser output mode, and preliminarily optimize the laser zirconium infiltration process window to obtain a preliminary optimized process window: the laser spot diameter is 1.5~3.5mm, the defocus amount is -2.0mm, and the laser peak power is 600~ 900W, scanning speed is 6-15mm / s, powder feeding volume is 3-7g / min;

[0021] Step 2: Randomly select a set of preliminary optimized process parameters, use the finite element heat transfer model to calculate the three-dimensional temperature field of the molten pool under this parameter, and extract the temperature change curve experienced by the point in the middle of the sediment layer, that is, the temperature change at the fixed point of the molten pool curve; respectively extract the peak temperature Tmax of the fixed-point tem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap