Combined spring shock absorber

A shock absorber and combined technology, which is applied in variable capacity pump components, machines/engines, liquid variable capacity machines, etc. It can solve the problems of ineffective spring noise reduction, environmental noise pollution, and easy damage to air compressors. and other problems, achieving the effects of obvious noise reduction effect, obvious buffering effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

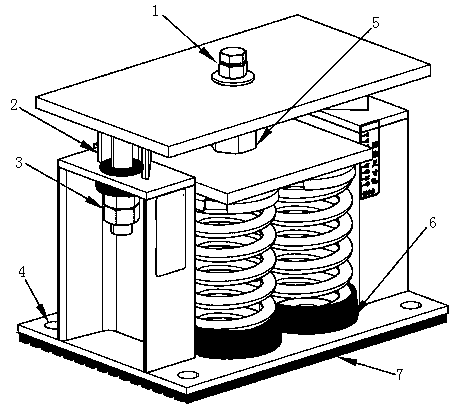

[0011] A combined spring shock absorber, the shock absorber includes a base, bolt fixing holes 4 and support frames symmetrically arranged on the base, the bolt fixing holes 4 are symmetrically arranged at the four corners of the base, and the support frames are respectively A bolt group 3 is provided, and the bolt group 3 is respectively provided with a rubber sleeve and a pressure pad 2. The upper part of the bolt group 3 is connected with an upper pressure plate, and a lower pressure plate is arranged below the upper pressure plate. The pressure plate is arranged between the supporting frames, and the shock absorber also includes a fixing bolt 1, and the fixing bolt 1 vertically passes through the upper pressure plate and the lower pressure plate, and a pair of damping springs are connected to the lower part of the lower pressure plate.

[0012] The support frame is box-shaped, and the side facing the outside of the support frame is open.

[0013] The lower surface of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com