T-shaped unilateral bolt fastener

A technology for unilateral bolts and fasteners, which is applied in the direction of threaded fasteners, screws, connecting components, etc., which can solve the problem of inability to use bolts and large nuts to connect fastening methods, unsatisfactory comprehensive mechanical properties, and inability to operate on both sides, etc. problems, achieve fast and efficient installation work, simple and rapid installation process, and improve the convenience of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

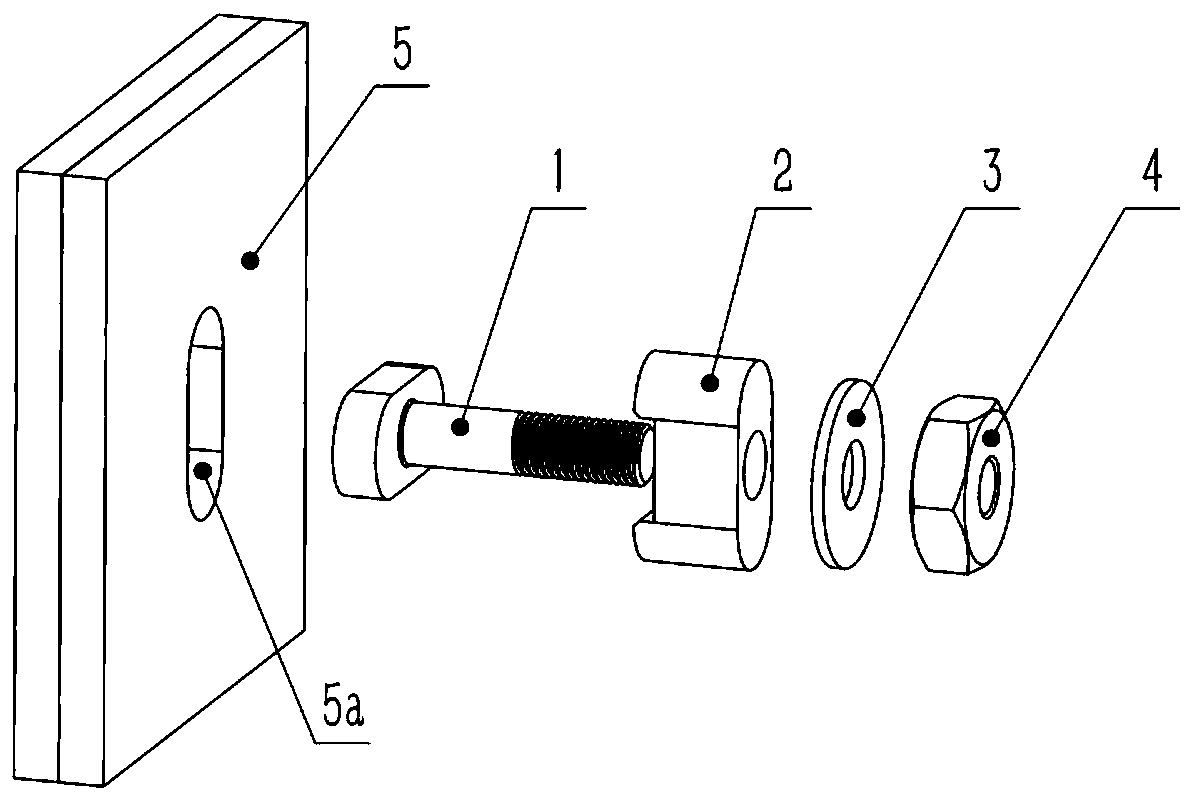

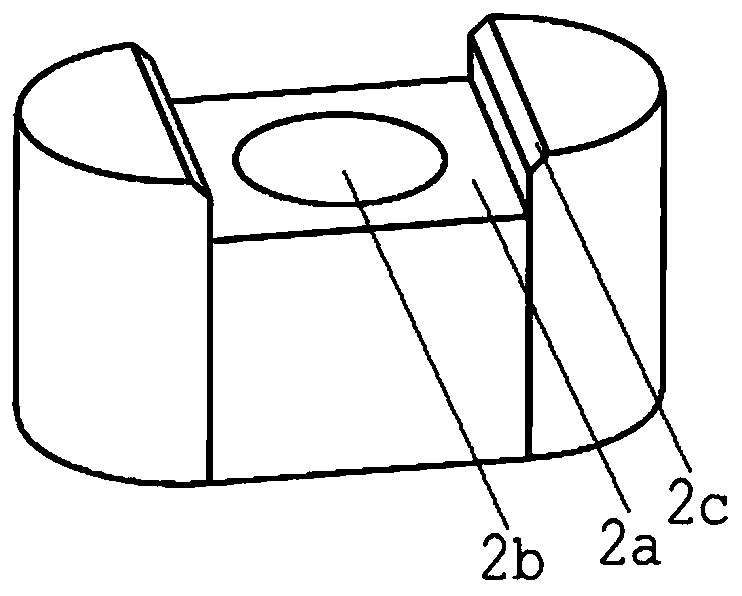

[0031] Such as figure 1 As shown, the present invention provides a T-shaped unilateral bolt fastener, including a bolt 1 and a bolt sleeve 2 respectively sleeved on the bolt 1, a large washer 3 and a large nut 4, and the connecting piece 5 is correspondingly processed with mounting hole 5a, after the installation is completed, the bolt head 1a of the bolt 1 is set on the inner side of the connecting piece 5, the bolt sleeve 2 is set in the mounting hole 5a, and the washer 3 and the large nut 4 are sequentially set on the installation side of the connecting piece 5. Among them, the bolt head 1a and the bolt shank 1b form a T-bolt.

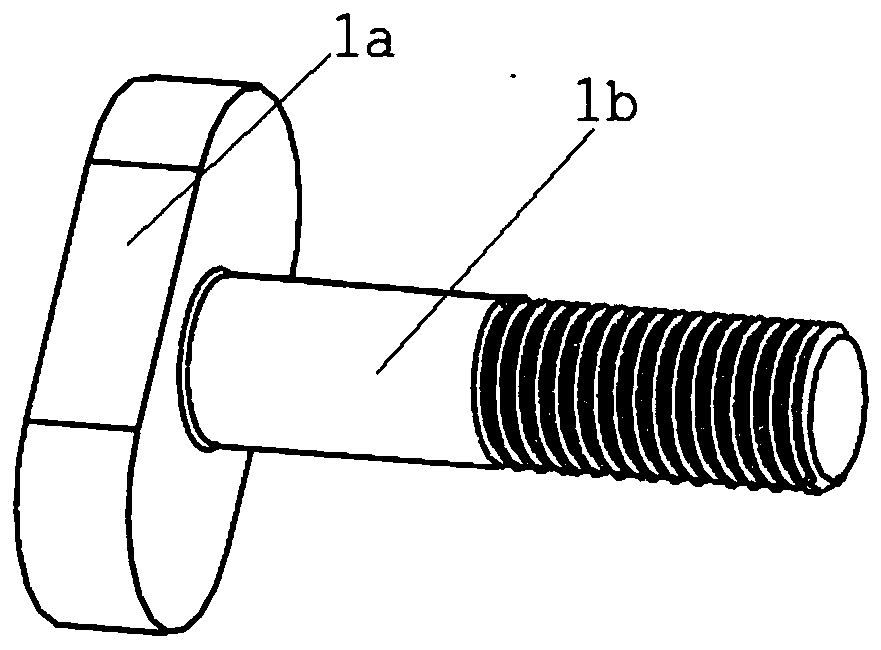

[0032] Such as figure 2 As shown, the T-shaped bolt includes a bolt head 1a and a bolt shank 1b that are connected to each other. The bolt head 1a is a bolt head with a type A flat key structure, and the bolt shank 1b protrudes from the centroid of the section of the bolt head 1a, and is Open external thread, the external thread adopts common thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com