A driving motor optimization method and system based on sound quality

An optimization method and technology for driving motors, which are used in the manufacture of motor generators, design optimization/simulation, electromechanical devices, etc., which can solve the problem of motor sound quality, which cannot fully reflect subjective feelings, sound pressure level or sound power level. Reduce and other problems, to achieve the effect of improving the sound quality of the motor, the optimization of structural parameters and control parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

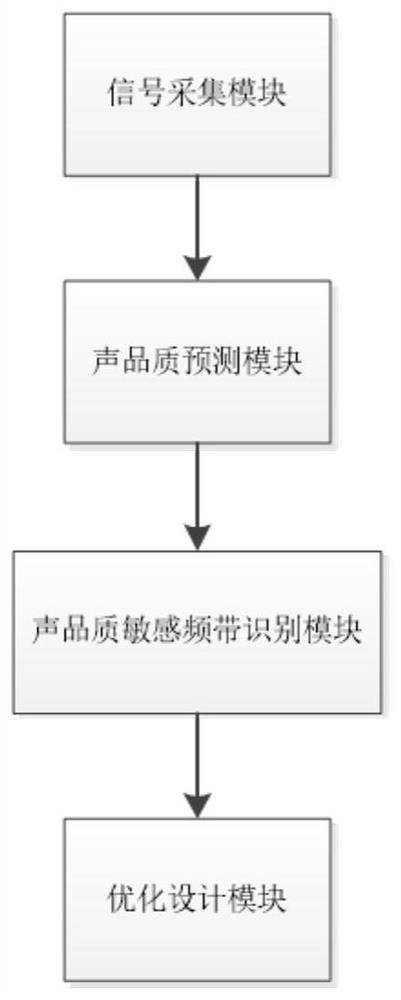

[0046] figure 1 Shown is a preferred implementation of the sound quality-based driving motor optimization system of the present invention, the sound quality-based driving motor optimization system includes a signal acquisition module, a sound quality prediction module, a sound quality sensitive frequency band identification module and optimization module;

[0047] The signal acquisition module is used to collect motor noise samples of different rotational speeds and different torques;

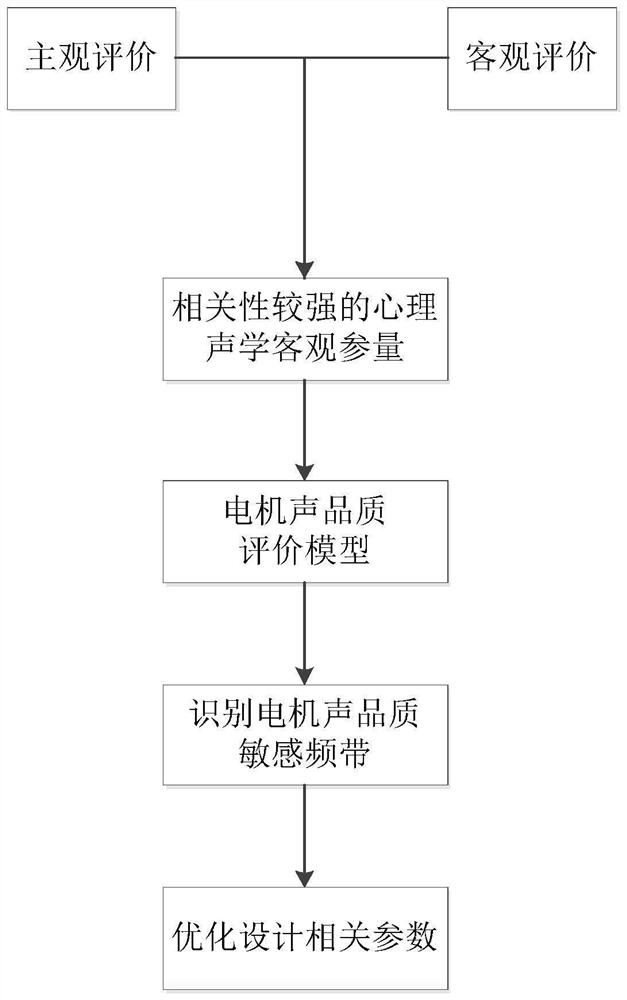

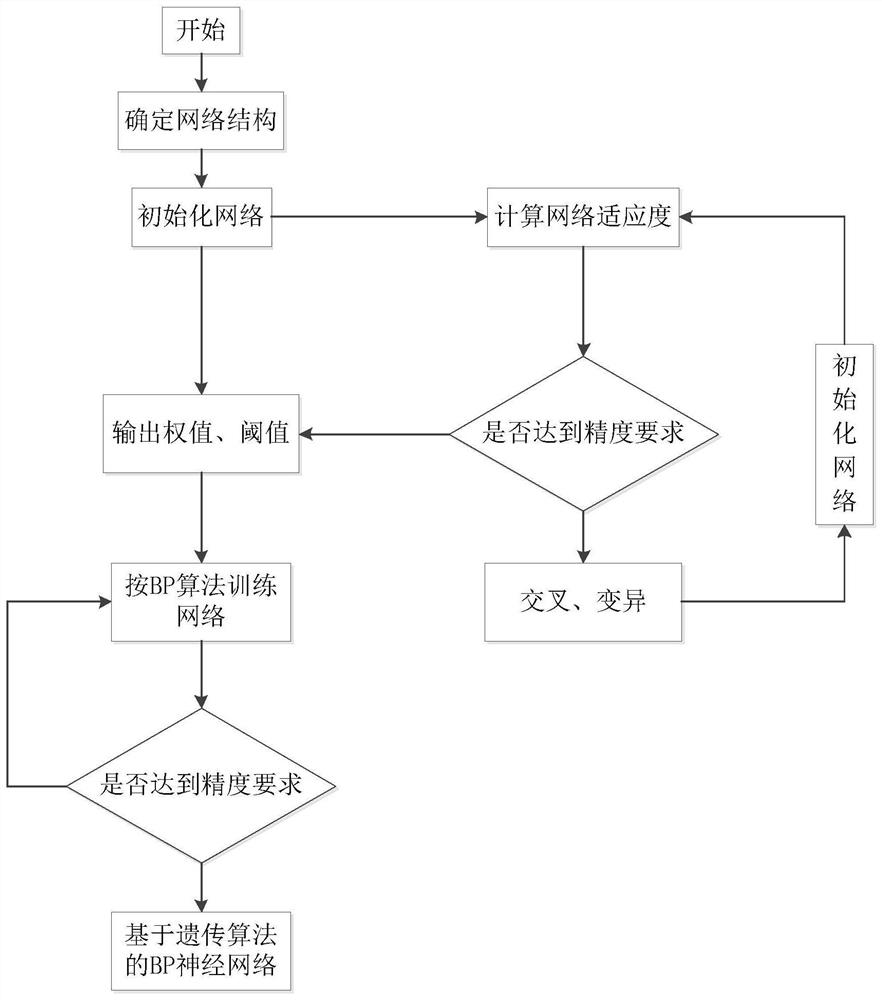

[0048] The sound quality prediction module is used to perform subjective evaluation and psychoacoustic objective parameter calculation on the collected motor noise samples, and establish a motor sound quality prediction model;

[0049] The sound quality sensitive frequency band identification module is used to determine the frequency bands that are positively correlated with the sound quality of the motor, analyze and calculate the sensitivity coefficient of each frequency band, and determine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com