Monitoring camera with good shock resistance and function of automatically cleaning lens

A monitoring camera and automatic cleaning technology, which is applied in the field of monitoring cameras, can solve the problems of easy damage, manual regular maintenance, and the lens part of the camera cannot be cleaned automatically, so as to avoid shock damage and avoid splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

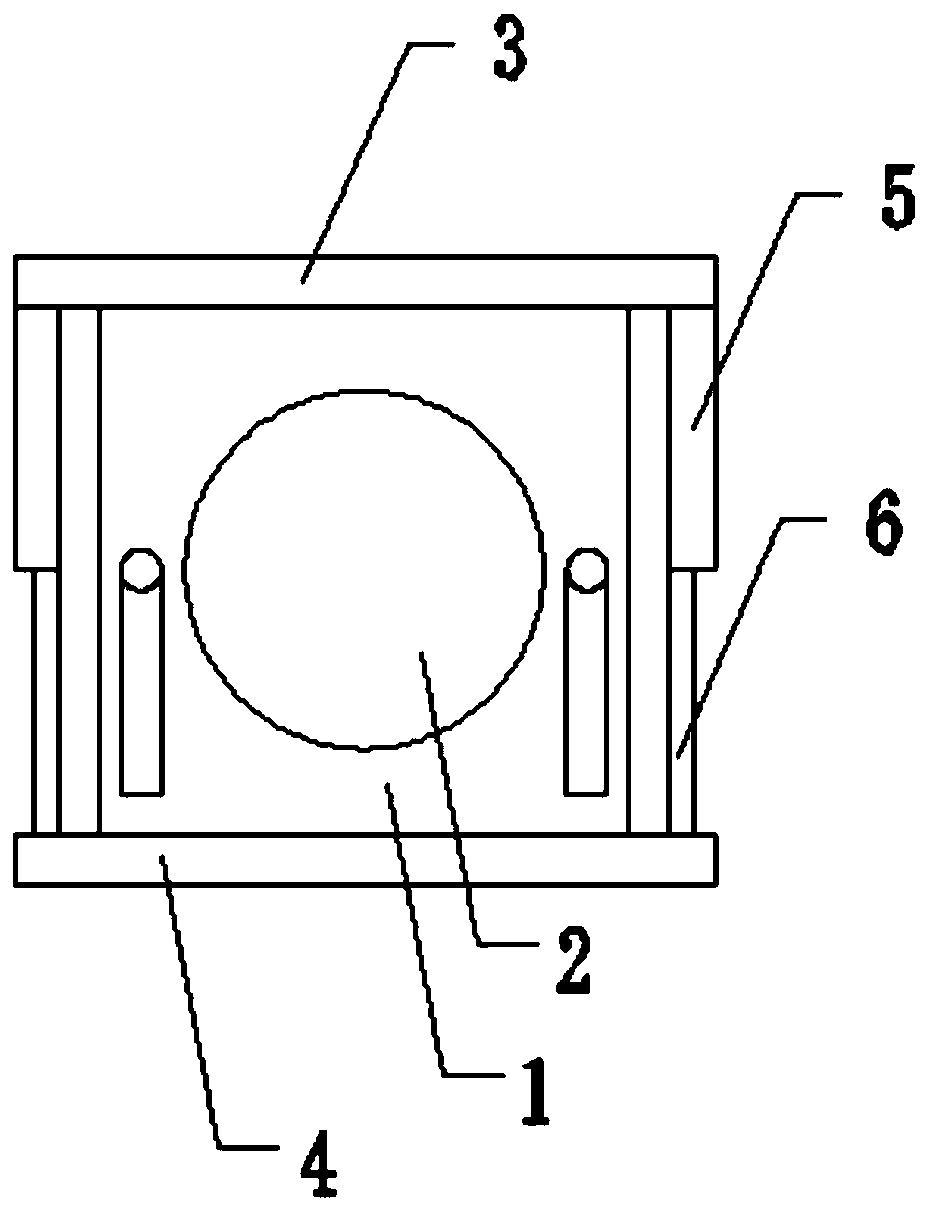

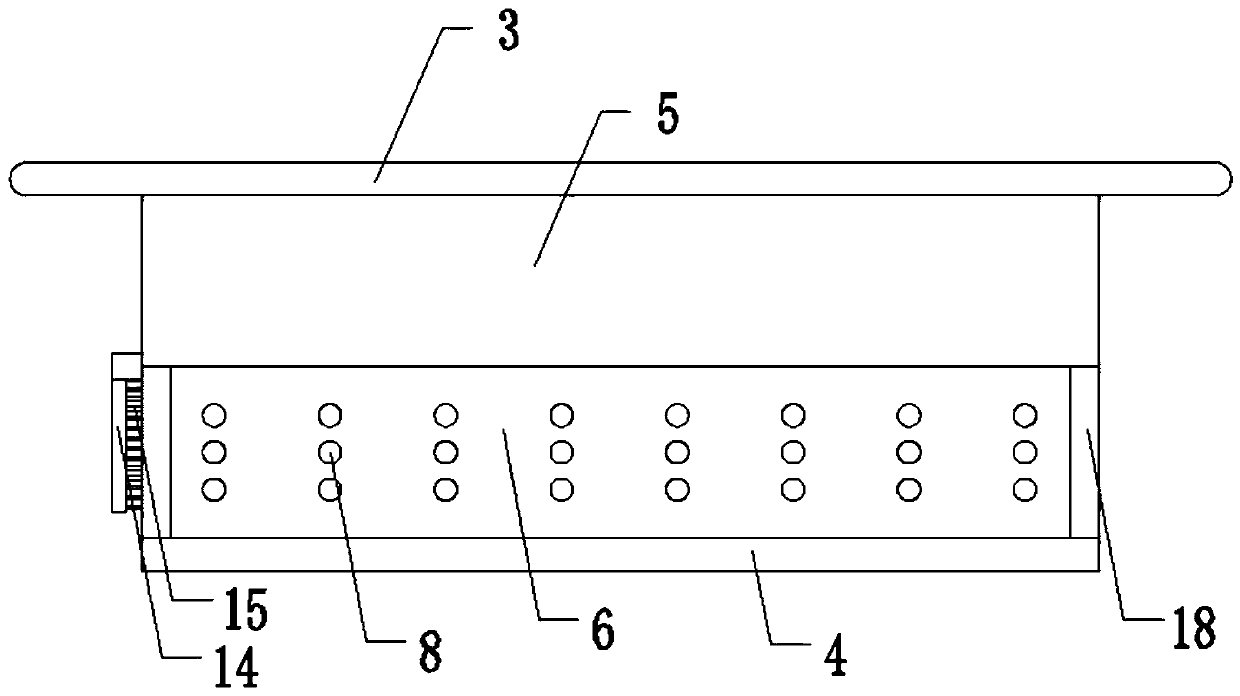

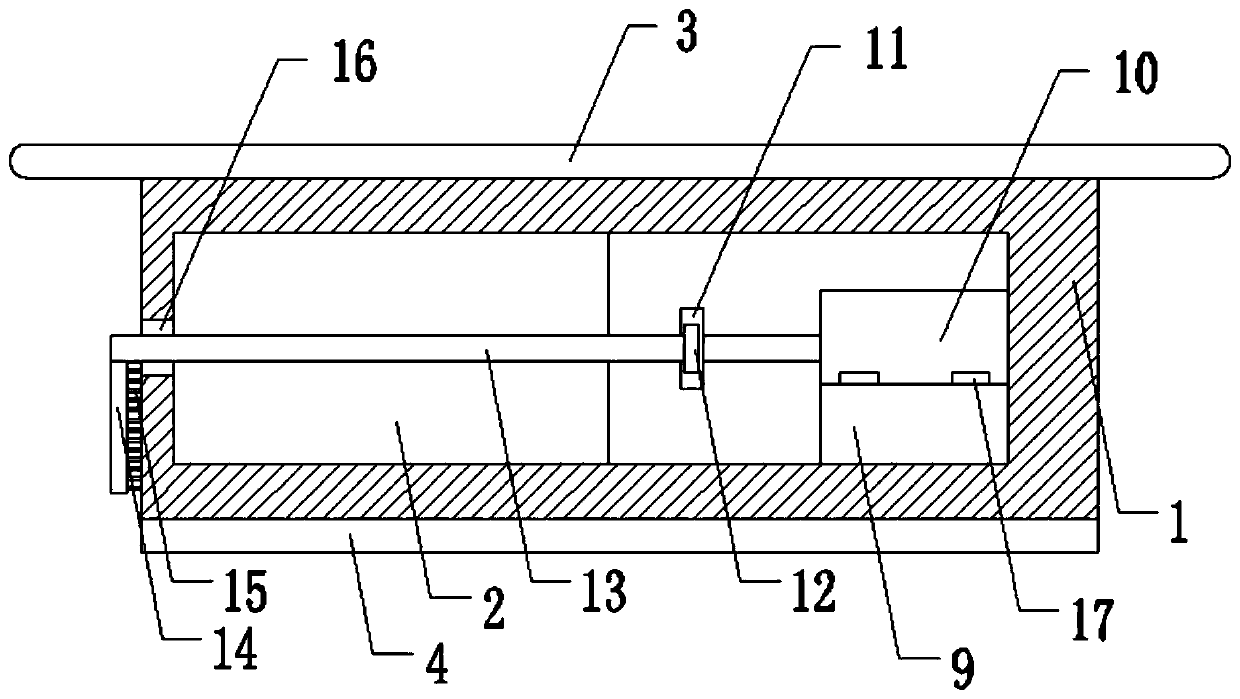

[0026] see Figure 1-4 , the present invention provides a technical solution: a surveillance camera with good shock resistance and capable of automatically cleaning the lens, comprising a mounting case 1, a camera body 2 fixedly inserted in the middle of the mounting case 1, and a top support of the mounting case 1 There is a top plate 3, the top plate 3 prevents the upper external force from directly impacting the installation shell 1 and splashing of water, the left and right sides of the bottom of the top plate 3 are connected with the cushioning shell 5 by screws, and the bottom of the installation shell 1 is supported by the bottom plate 4, the bottom plate 4 The left and right sides of the top are all connected with a cushioning plate 6 by screws, and the cushioning plate 6 is movably inserted in the bottom of the cavity of the cushioning shell 5, and the top of the cushioning plate 6 and the bottom of the cavity of the cushioning shell 5 are connected by screws. The spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com