Automatic fried bread stick dough blank folding and forming machine

A technology of forming machine and dough embryo, applied in the direction of dough forming machinery or equipment, dough extruder, dough forming and cutting equipment, etc., can solve the problems of uneven top and bottom of the laminations, unsightly appearance, inconsistent water flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The awakened noodles are pressed into the required specifications by the noodle rollers and automatically fall onto the conveyor belt for slitting and powdering. After the pressing, the embryos are operated by the stacking machine;

[0029] The method of using the automatic stacking and forming machine for fried dough sticks includes the following steps:

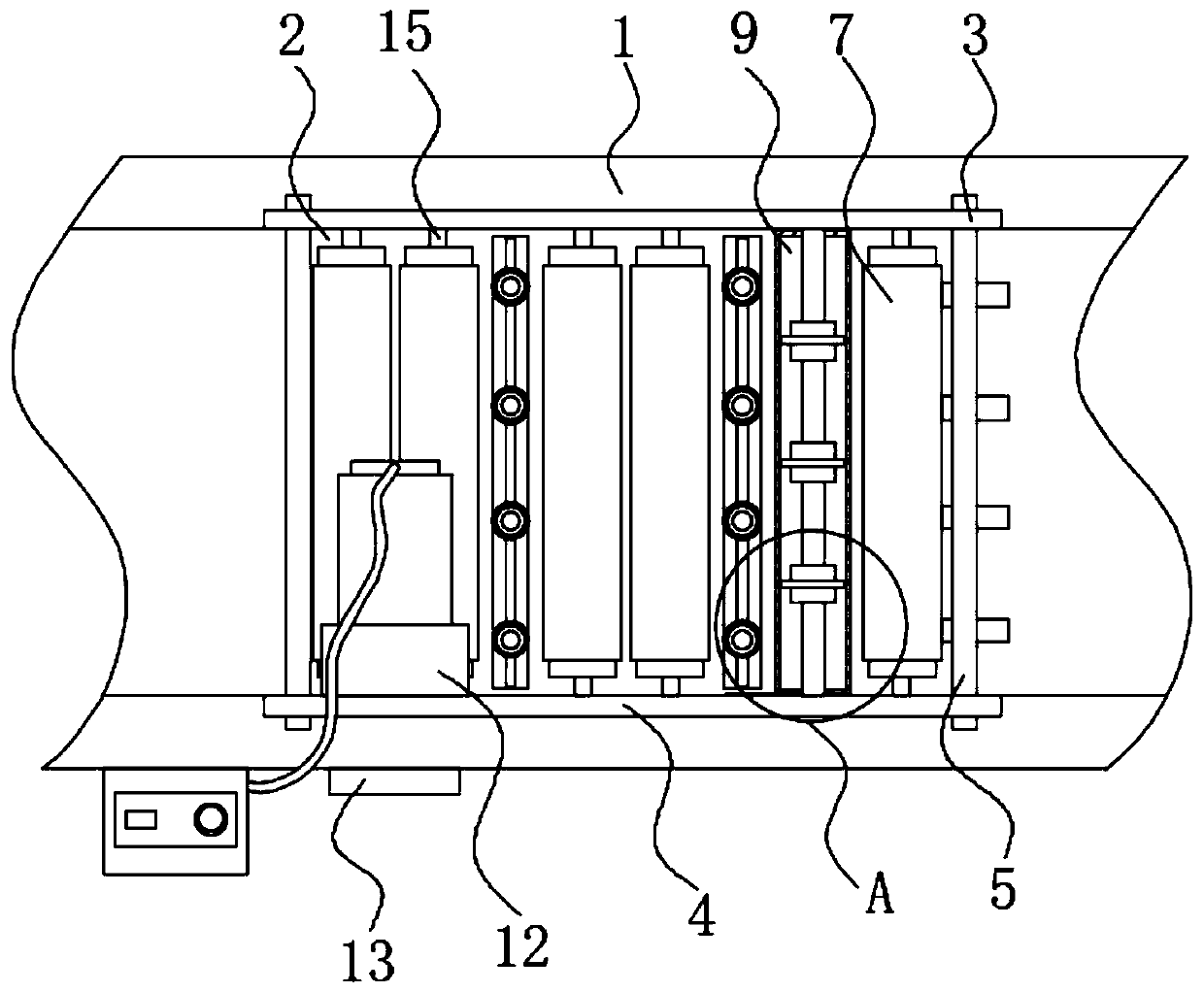

[0030] S1. After double-cutting the dough blank according to the required specifications, the conveyor table 1 conveys the dough blank through the input end of the machine body 2, crosses up and down and enters the multiple sets of conveying rollers 7 of the stacking machine, and the conveying roller 7 conveys the dough;

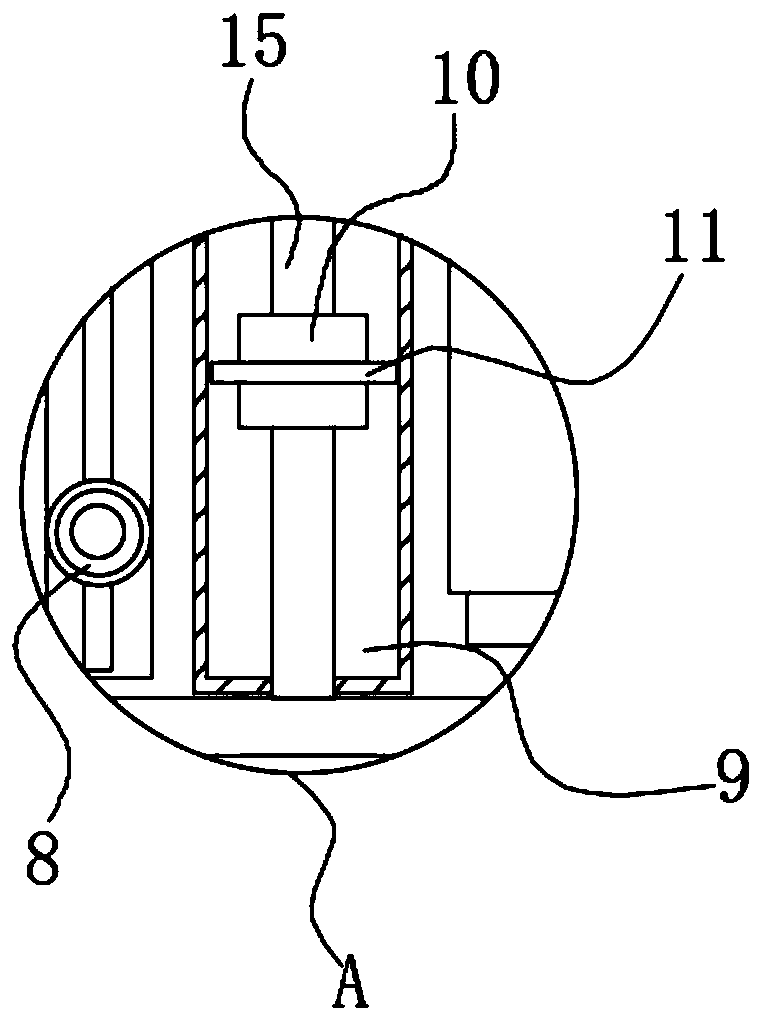

[0031] S2. During the transfer process of the dough blank in step S1, the width of the required dough blank is fixedly transmitted through the gap between two positioning shafts 8;

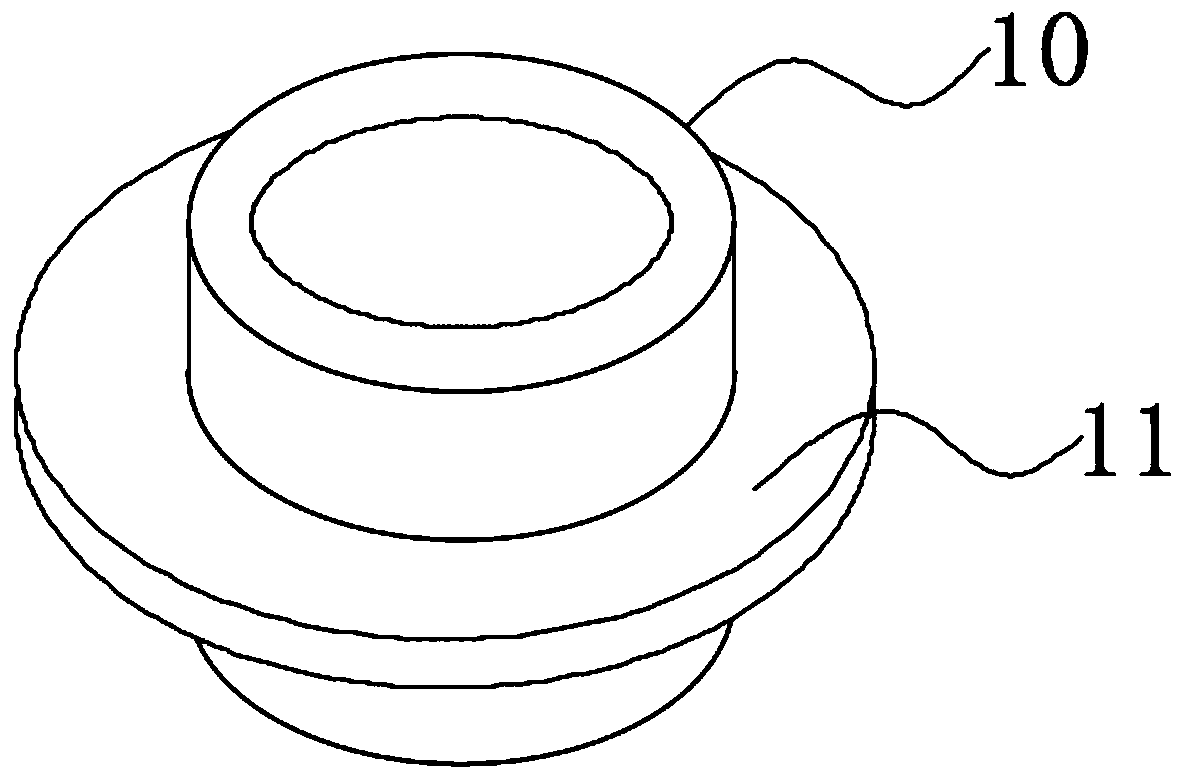

[0032] S3. The water tank under the water-dipping shaft 10 rotates synchronously through the chain 6, and the small r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com