Fire fighting truck boom device and fire fighting truck

A fire truck and boom technology, which is applied in the field of fire truck boom devices and fire trucks, can solve the problems of unfavorable long-distance water spraying, limited expansion and contraction of conveying pipes, and difficulty in controlling the direction of the exit of conveying pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

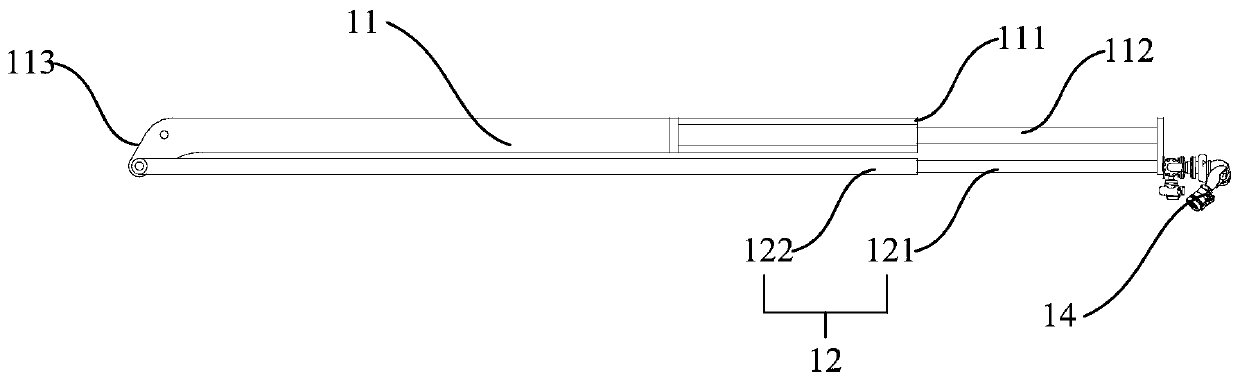

[0043] Provided in this embodiment is a fire truck boom device 1, such as figure 1 As shown, the fire engine boom device 1 includes a support arm 11 , a telescoping water pipe 12 and a spray gun assembly 14 . The support arm 11 includes a first end 111 and a second end 113 located in the length direction, the first end 111 is fixedly provided with a telescopic oil cylinder 112, and the telescopic direction of the telescopic oil cylinder 112 is set along the length direction of the support arm 11, so that the telescopic oil cylinder 112 It can expand and contract relative to the first end 111 along the length direction of the support arm 11 . The telescopic water pipe 12 includes a first pipe section 121 and a second pipe section 122 , the first pipe section 121 and the second pipe section 122 are socketed together, and the first pipe section 121 can extend or retract relative to the second pipe section 122 . The first pipe section 121 and the second pipe section 122 extend al...

Embodiment 2

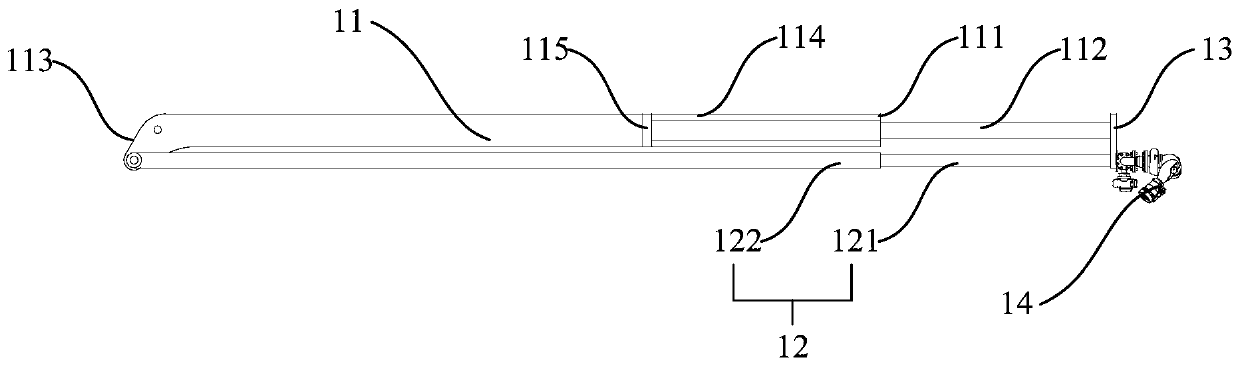

[0045] Provided in this embodiment is a fire truck boom device 1, such as figure 2 As shown, the fire engine boom device 1 includes a support arm 11 , a telescoping water pipe 12 and a spray gun assembly 14 . The first end 111 of the support arm 11 forms a cylindrical inner cavity 114 with an opening, and an inner connector 115 is fixed at the end of the cylindrical inner cavity 114 away from the opening; The cylinder barrel of the oil cylinder 112 is arranged in the cylindrical inner cavity 114 and is connected with the inner connector 115. One end of the piston rod of the telescopic oil cylinder 112 faces the open end of the cylindrical inner cavity 114, and can be directed toward the cylindrical inner cavity 114. Extend outward or retract inward. The telescopic water pipe 12 includes a first pipe section 121 and a second pipe section 122. The second pipe section 122 is sheathed on the outside of the first pipe section 121 and communicates with the first pipe section 121. ...

Embodiment 3

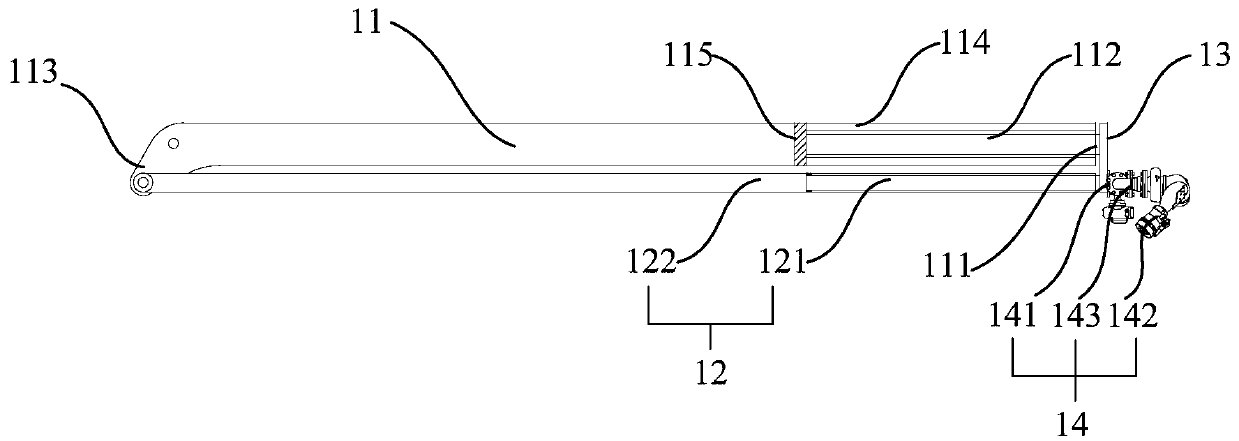

[0048] The fire engine boom device provided in this embodiment is further improved on the basis of the second embodiment. Such as image 3 As shown, the spray gun assembly 14 specifically includes a connecting seat 141, a spray gun 142 and a connecting pipe 143. The two ends of the connecting seat 141 are detachably connected to the flange connector 13 and the spray gun 142 respectively, and the spray gun 142 can be moved relative to the connecting seat 141. Rotate to change the water spraying direction by the rotation of the spray gun 142 when the spray gun assembly 14 performs the water spray operation. Both ends of the connecting pipe 143 communicate with the spray gun 142 and the first pipe section 121 of the telescopic water pipe 12 , so that the spray gun 142 communicates with the telescopic water pipe 12 .

[0049] Further, the telescopic stroke of the telescopic water pipe 12 is the same as the telescopic stroke of the piston rod of the telescopic oil cylinder 112, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com