Electric vibrating feeder

A feeder, electric vibration technology, applied in solid separation, classification, chemical instruments and methods, etc., can solve the problems of affecting the iron content of batch materials, small contact area of screen mesh, damage to raw materials, etc., and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

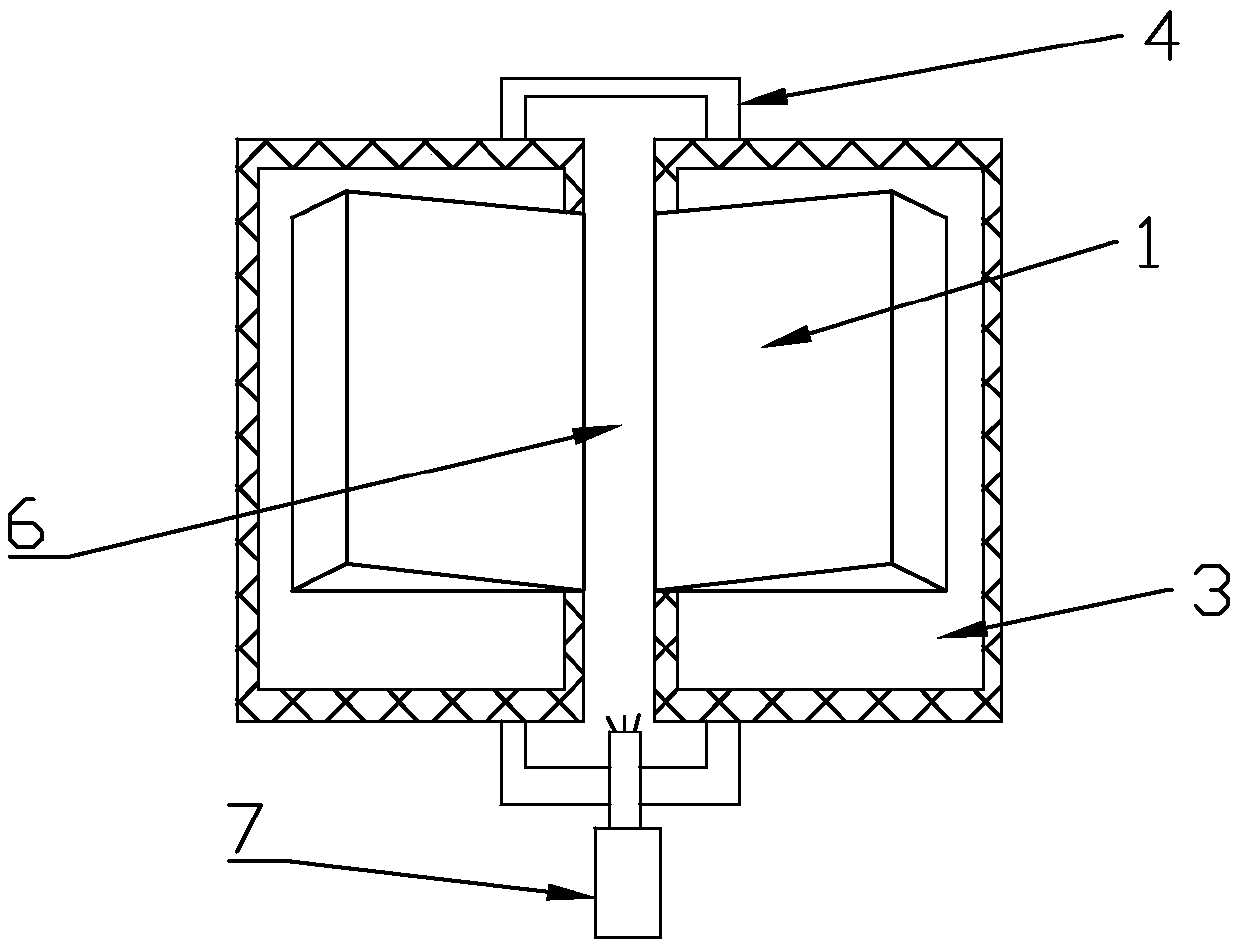

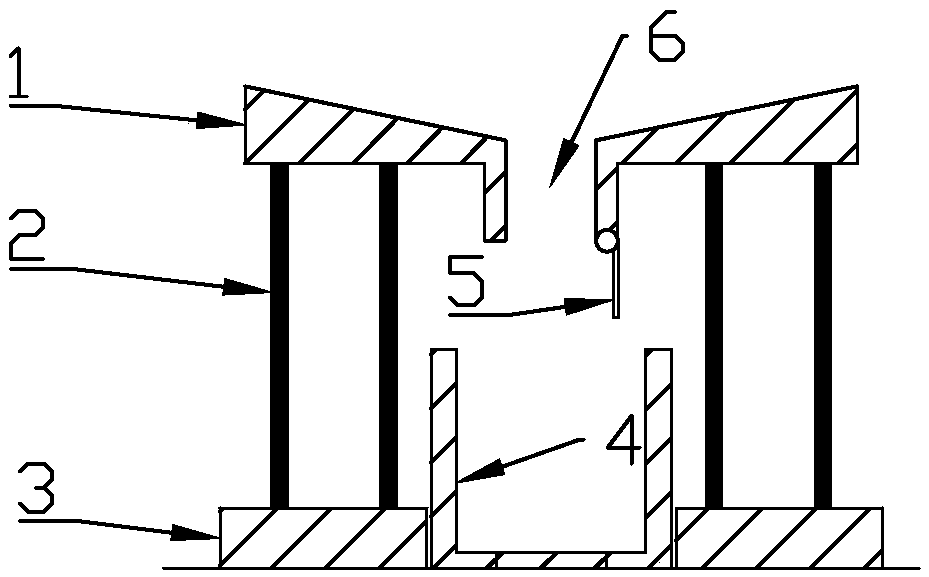

[0014] like figure 1 The shown electric vibrating feeder includes a vibrating table 1, a spring plate 2, a vibrating base 3 and a secondary material storage bucket 4, the bottom of the vibrating table 1 is equipped with a spring plate 2, and the spring plate 2 is fixed on the vibrating base 3 above; the vibrating table 1 is divided into two parts, the left and the right, butted to form a Y-shaped vibrating table, and its vertical part is an open structure 6, and the secondary material storage bucket 4 is placed directly below the bottom; because the vibrating table 1 is divided into two parts, the left and the right Not connected, can be moved and adjusted, and then adjust the width of the open structure 6, adjust the gap between the two according to the actual situation, preferably 20-35mm, and set a high-pressure blowing port at one end of the vibrating table for purging raw materials .

[0015] The vibrating table 1 is made of stainless steel; the surface of the stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com