A Welding Method Applicable to Thick Plate Aluminum Alloy

A welding method and aluminum alloy technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problems of large welding deformation, high requirements for auxiliary tooling, poor accessibility, etc., and increase the thickness of blunt edges , to achieve the effect of shape control and controllability adjustment, and improve welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

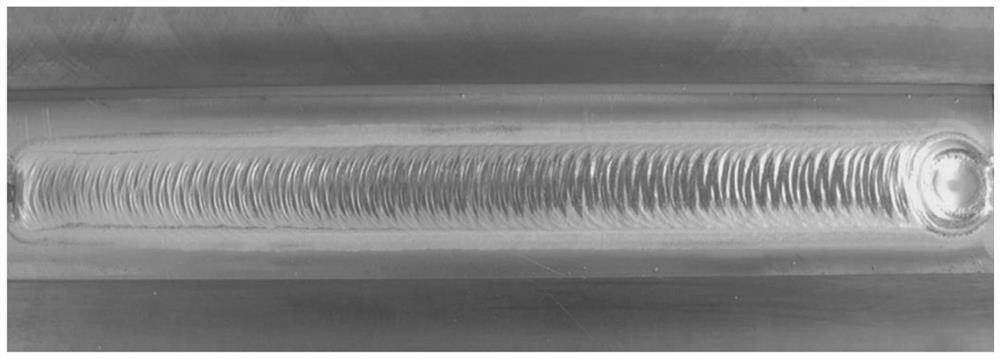

[0078] Embodiment 1, the third layer of cover welding 22 is AC TIG argon arc welding without torch swing

[0079] The invention ensures that one weld can cover the entire groove width through precise adjustment of welding process parameters, and at the same time ensures that the fusion zones of the two-layer cover welds do not overlap, thereby avoiding the deterioration of the structure and performance of the weld. Like the second layer of cover welding 21, low-frequency pulse variable polarity TIG welding is also used, in order to obtain the final appropriate weld shape, that is, to maintain an appropriate weld shape coefficient (ratio of fusion width to penetration depth), the third layer of cover welding 22 increases the welding current compared with the second layer of cover welding 21, and at the same time appropriately increases the arc voltage, so that the arc voltage and welding current maintain a proper match relation;

[0080] In this embodiment, the parameters of ...

Embodiment 2

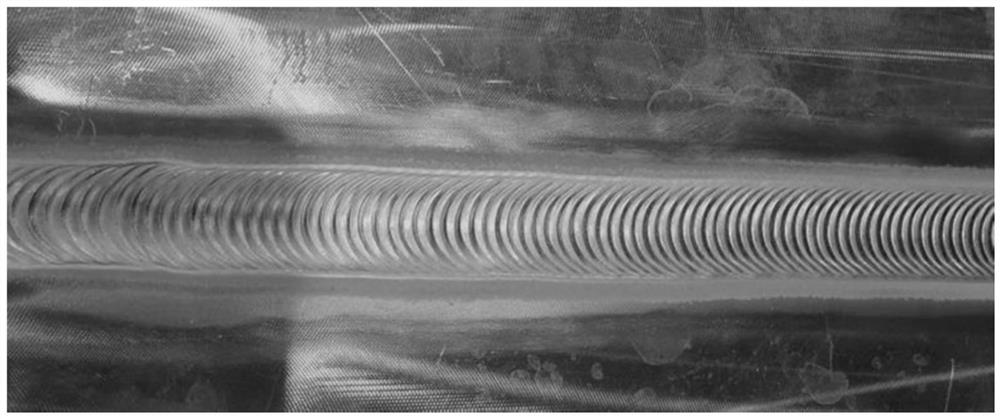

[0086] Embodiment 2, the third layer cover surface welding 22 is AC TIG argon arc welding with torch swing

[0087] In the present embodiment, the parameters of the U-shaped groove are a=18mm, b=12mm, R=3mm, p=12mm, δ=15mm, the gap between the two workpieces 10 to be welded is 0.2mm, and the staggered seam is 0.3mm. mm;

[0088] Welding conditions for tack welding: welding current 240A, welding speed 15m / h;

[0089] Welding conditions for the first layer of bottom welding 20: use arc welding to carry out bottom welding on the two workpieces 10 to be welded, the diameter of the selected tungsten pole is 5mm, the angle of the tip of the tungsten pole is 60°, the diameter of the tip is 2.5mm, and the length of the tip is extended 8mm, adjust the distance between the tip of the tungsten electrode and the workpiece 10 to be 2mm before welding; the welding current is 320A, the welding speed is 10m / h, the arc voltage is 14.5V, the shielding gas is 99.999% high-purity helium, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com