Tubular product cutting device with polishing function

A cutting device and pipe material technology, applied to machine tools, grinders, manufacturing tools, etc., which are suitable for grinding the edge of workpieces, can solve the problems of time-consuming and labor-consuming, prolong production time, etc., and achieve the reduction of beating, avoiding beating, and stable support and the effect of limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

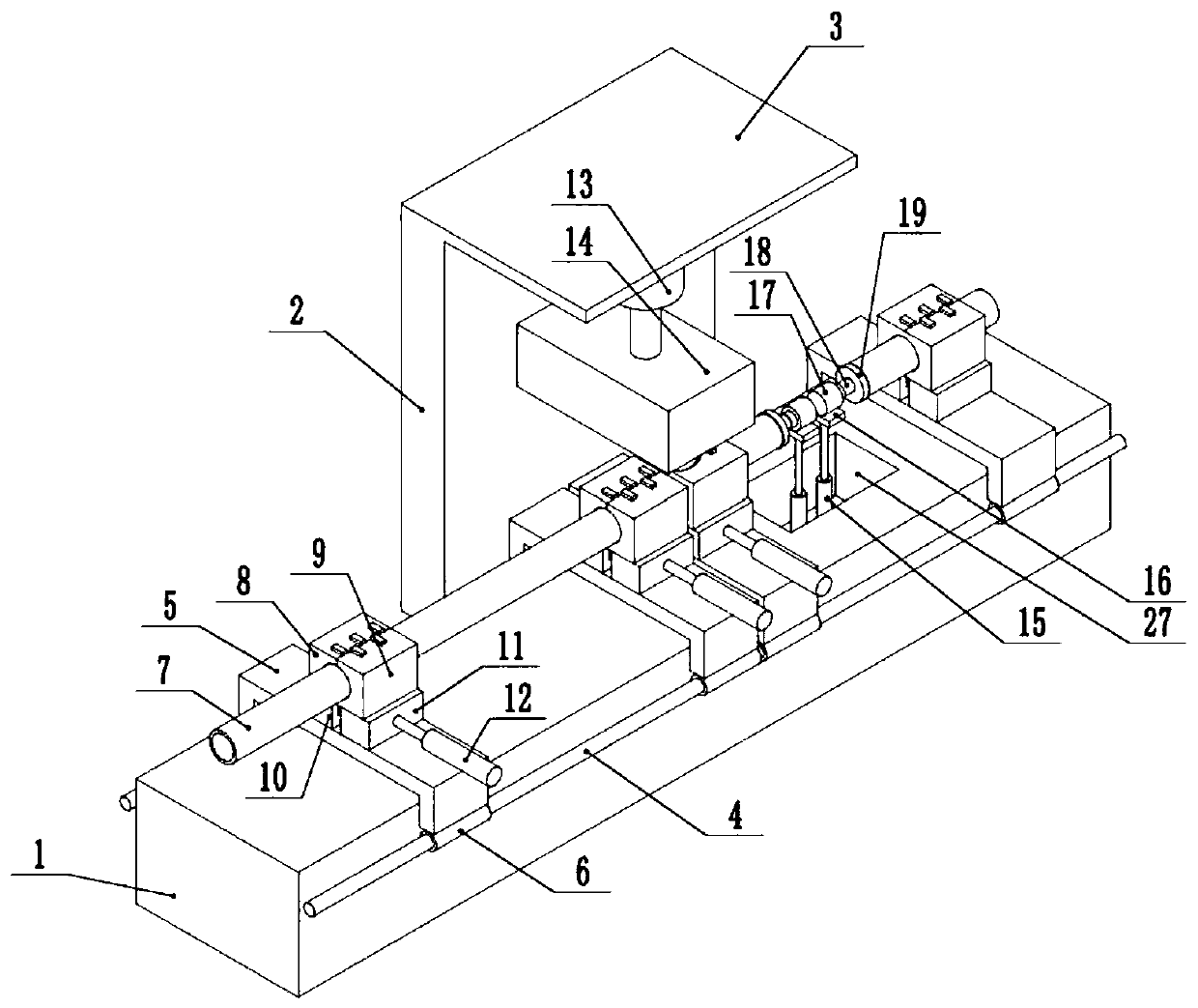

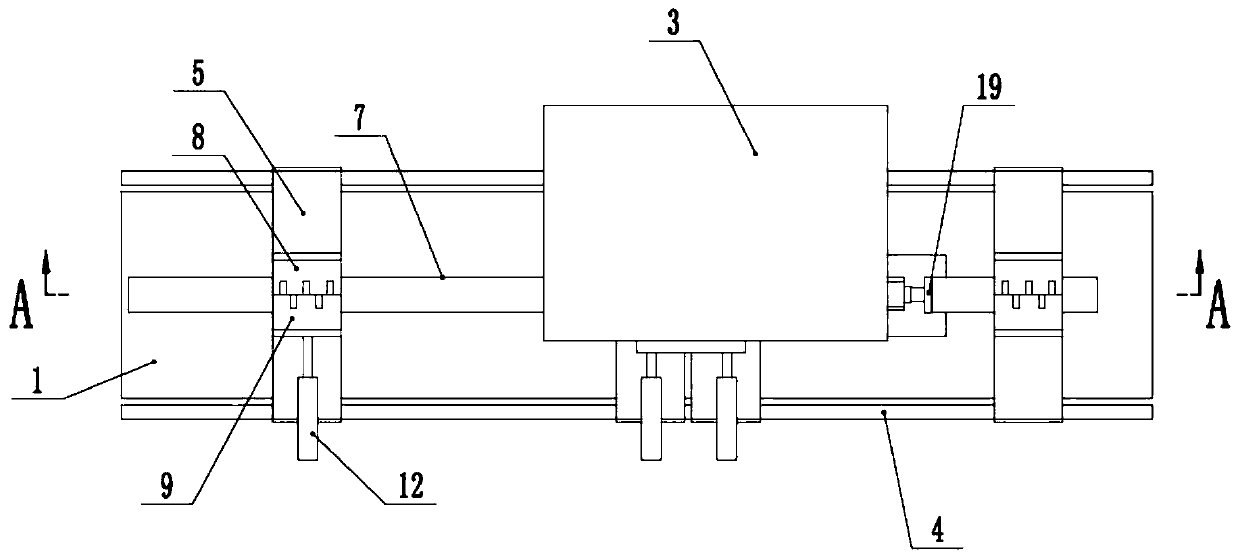

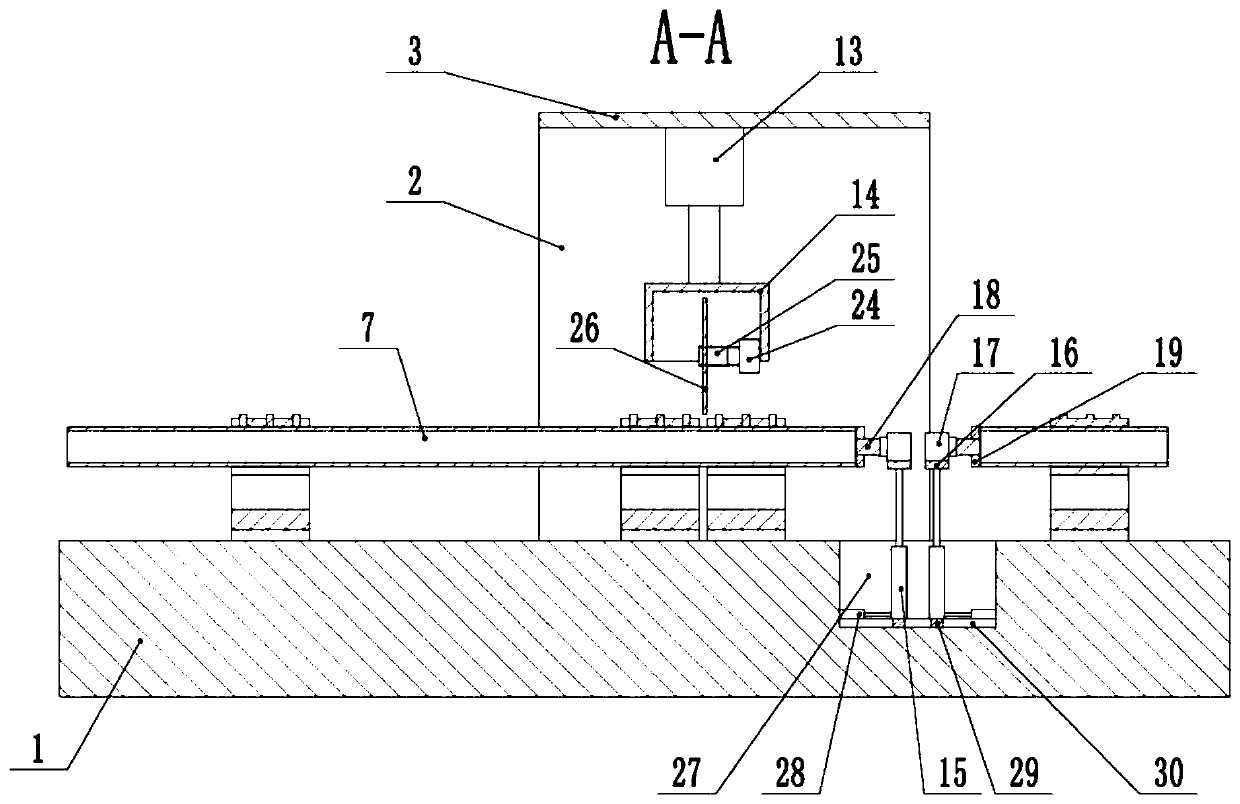

[0037] The embodiment is basically as attached figure 1 Shown: a pipe cutting device with a grinding function, including a worktable 1, the workbench 1 is a cuboid structure, and the workbench 1 is sequentially provided with a transmission unit, a clamping unit and a retrieving unit along the transmission direction of the pipe 7, and the transmission The structure of the unit, gripping unit and retrieving unit is identical. A cutting unit is provided above the clamping unit, and a grinding unit is provided on the side of the clamping unit close to the material taking unit.

[0038] In this embodiment, two clamping units are provided, and the two clamping units are arranged parallel to each other. The clamping unit, the conveying unit and the retrieving unit all include a sliding table 5, and the two ends of the sliding table 5 are aligned with the conveying direction of the pipe. Both sides of workbench 1 are slidingly connected. In this embodiment, guide rails 4 are welded an...

Embodiment 2

[0050] Such as Figure 4 and Figure 5 As shown, a pipe cutting device with a grinding function differs from Embodiment 1 in that an installation cavity 31 is provided on the workbench 1, and the installation cavity 31 is located between the retrieving unit and the storage cavity 27, and the installation cavity 31 A discharge cylinder 22 is provided, the bottom of the discharge cylinder 22 is fixed to the bottom of the installation chamber 31 by bolts, the output shaft of the discharge cylinder 22 is fixedly connected with a discharge plate 23 by bolts, and the discharge plate 23 is vertical to the pipe material 7 Right on set.

[0051] In this embodiment, the longitudinal section of the unloading plate 23 is arc-shaped, and one end of the unloading plate 23 with an arc surface is arranged opposite to the pipe material 7. A material guide plate 20 is arranged on the workbench 1, and the material guide plate 20 is located at the On the right side of the material unit, the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com