A building tile with heat reflection function and preparation method thereof

A technology of heat reflection and function, applied in the direction of architecture, building structure, covering/lining, etc., to achieve the effect of reducing indoor temperature, reducing emissions, and improving living comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

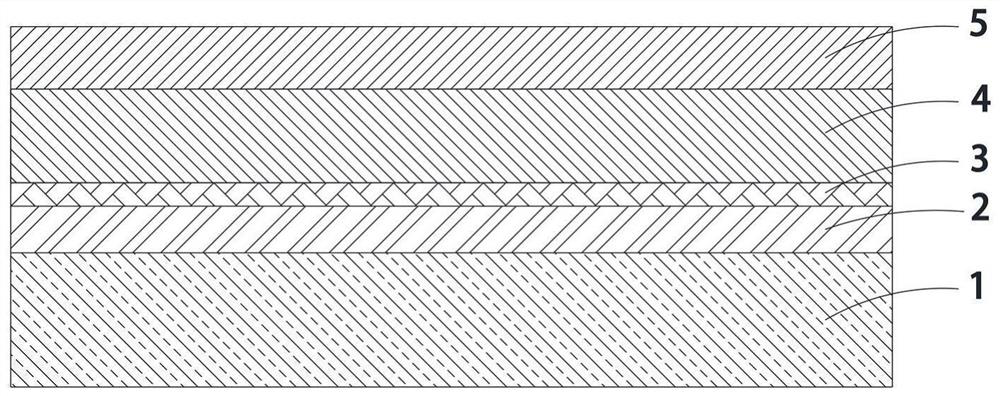

[0036] An architectural ceramic tile with heat reflection function, comprising from bottom to top: an embryonic body layer, a surface glaze layer, a high reflection layer, a protective layer and a transparent glaze layer; the high reflection layer includes Mo and Ag, rutile type TiO 2 , its mass ratio is 1:7.5:1.5, and its thickness is 5 μm; the protective layer includes SiO 2 , microprisms are randomly distributed on the protective layer, and the thickness of the protective layer is 150nm.

[0037] The preparation method of the architectural ceramic tile with reflective function is as follows: dry pressing and molding of ceramic tile powder, drying to obtain a green body layer, and applying a 0.3mm surface glaze on the green body layer to obtain a surface glaze layer; way to combine Mo with Ag and rutile TiO 2 The nano-composite material is applied on the surface glaze layer to obtain a high-reflection layer; the protective layer is obtained by thermal spraying on the high-r...

Embodiment 2

[0039] An architectural ceramic tile with heat reflection function, comprising from bottom to top: a body layer, a surface glaze layer, a high reflection layer, a protective layer and a transparent glaze layer; the high reflection layer comprises Mo, Ag, Y 2 O 3 , its mass ratio is 1:5:1, and its thickness is 8 μm; the protective layer includes SiO 2 , microprisms are randomly distributed on the protective layer, and the thickness of the protective layer is 100 nm.

[0040] The preparation method of the architectural ceramic tile with reflective function is as follows: dry pressing and molding of ceramic tile powder, drying to obtain a green body layer, and applying a 0.4mm surface glaze on the green body layer to obtain a surface glaze layer; way to combine Mo with Ag, Y 2 O 3 The nano-composite material is applied on the surface glaze layer to obtain a high-reflection layer; the protective layer is obtained by thermal spraying on the high-reflection layer; transparent gla...

Embodiment 3

[0042] An architectural ceramic tile with heat reflection function, comprising from bottom to top: an embryo body layer, a surface glaze layer, a high reflection layer, a protective layer and a transparent glaze layer; the high reflection layer includes Mo and Ag, and the mass ratio is 1 : 8, its thickness is 10 μm; the protective layer includes SiO 2 , microprisms are randomly distributed on the protective layer, and the thickness of the protective layer is 120nm.

[0043] The preparation method of the architectural ceramic tile with reflective function is as follows: dry pressing and molding of ceramic tile powder, drying to obtain a green body layer, and applying a 0.3mm surface glaze on the green body layer to obtain a surface glaze layer; The nanocomposite material of Mo and Ag is applied on the surface glaze layer to obtain a high-reflection layer; the protective layer is obtained by chemical plating on the high-reflection layer; a transparent glaze is applied on the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com