PET material with ultrahigh elongation at break and preparation method thereof

A technology of elongation at break and elongation, which is applied in the field of ultra-high elongation at break PET material and its preparation, can solve the problem of limiting the application range of toughened PET, limited increase in elongation at break, low elongation at break, etc. problems, to achieve the effect of improving hydrolysis resistance and chemical resistance, improving elongation at break, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

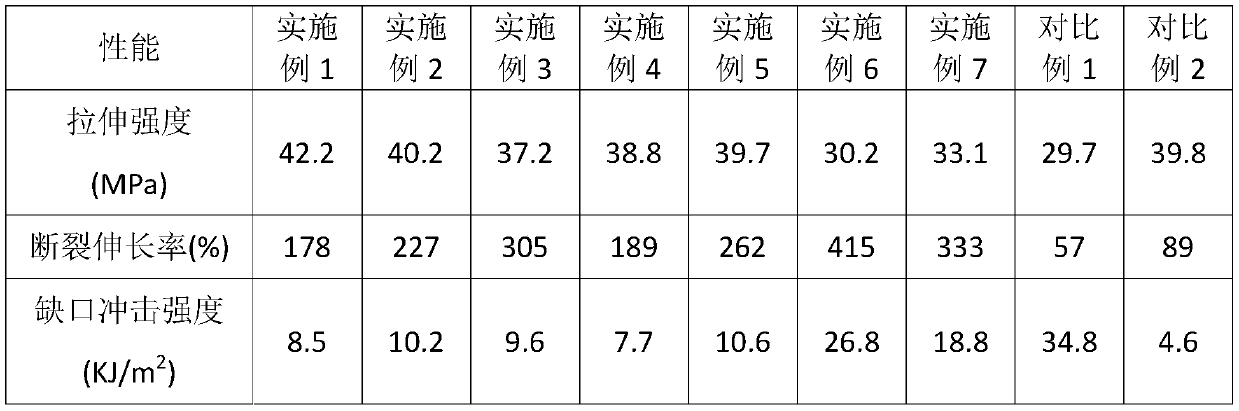

Examples

Embodiment 1

[0021] This embodiment provides a PET material with ultra-high elongation at break, which includes the following components in parts by weight: PET: 90 parts, AX8900: 2.5 parts, TPEE (H28DMG): 7.5 parts, antioxidant 1076: 0.1 parts , Antioxidant 168:0.1 part. Add PET, toughener and antioxidant to the high-speed mixer and mix evenly, then extrude and granulate the product through a twin-screw extruder. The temperature of each section of the extruder is controlled at 270, 280, 280, 280, 290, 295, 300°C, speed 200RPM.

Embodiment 2

[0023] This embodiment provides a PET material with ultra-high elongation at break, which includes the following components in parts by weight: PET: 87 parts, AX8900: 5 parts, TPEE (H55DMG): 7.5 parts, antioxidant 1076: 0.15 parts , Antioxidant: 0.2 parts of DLTDP. First add PET, toughener and antioxidant into the high-speed mixer and mix evenly, then extrude and granulate the product through a twin-screw extruder. The temperature of each section of the extruder is controlled at 275, 280, 280, 280, 290, 290, 295°C, speed 230RPM.

Embodiment 3

[0025] This embodiment provides a PET material with ultra-high elongation at break, which includes the following components in parts by weight: PET: 85 parts, PTW: 5 parts, TPEE (H28DMG): 10 parts, antioxidant 1010: 0.2 parts , 0.25 parts of antioxidant DLTDP. First add PET, toughener and antioxidant into the high-speed mixer and mix evenly, then extrude and granulate the product through a twin-screw extruder. The temperature of each section of the extruder is controlled at 275, 280, 280, 280, 290, 290, 295°C, speed 250RPM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com