Double-dynamic long-path two-workshop comprehensive scheduling method

A scheduling method and long-path technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve the problems of not considering the processed process, unsatisfactory product processing effect, and prolonged product completion time, so as to reduce the consumption of workshop resources , reduce the number of migrations, and achieve good scheduling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

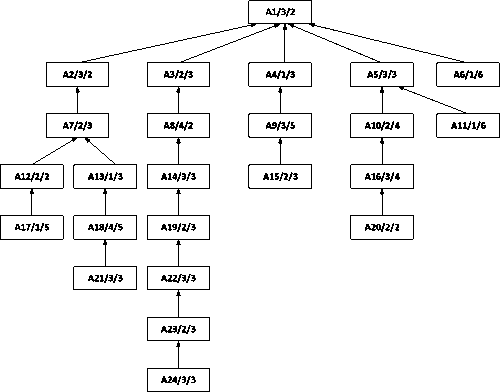

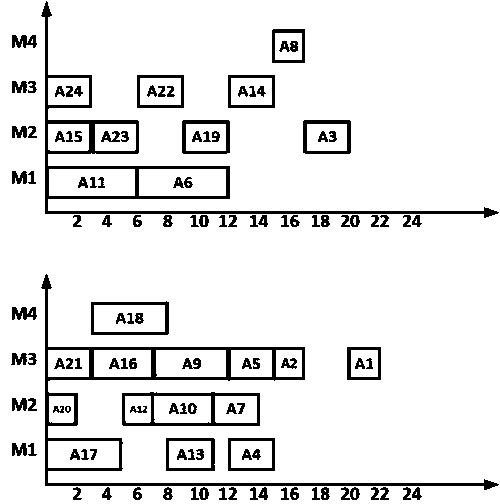

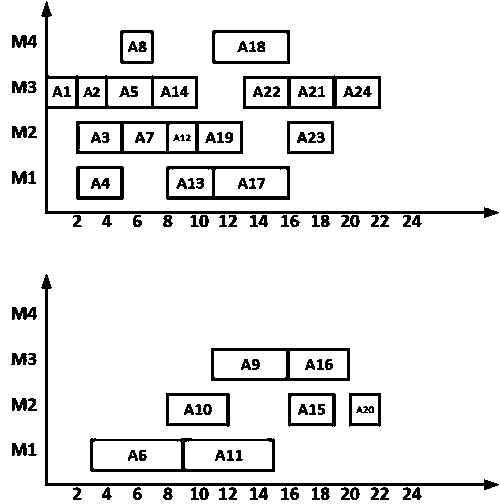

[0034] A dual-dynamic long-path two-shop comprehensive scheduling method, which is characterized in that the method mainly includes the following steps: according to the structure of the process tree, the number of layers is set from the leaf node to the root node and the scheduling is performed by layer; the dual-dynamic long-path sorting is adopted Strategy pre-scheduling, considering the delayed scheduling of processes caused by equipment occupation during the scheduling process, considering the impact of the end time of the processed processes for each layer of the process set to be scheduled, using a combination of static scheduling and dynamic scheduling to calculate the total path length and Pre-scheduling in descending order, thereby improving the accuracy of scheduling long paths; in order to realize product processing as soon as possible, an average delay strategy is proposed, considering the use of gaps in process processing to make equipment processing compact; in ord...

Embodiment 2

[0036] In the above-mentioned dual dynamic long-path two-shop comprehensive scheduling method, the specific implementation steps of the scheduling method 1 are as follows:

[0037] Specific implementation steps

[0038] Step 1: Enter device and product information.

[0039] Step 2: Obtain n layers of the product processing technology tree.

[0040] Step 3: Let i=1.

[0041] Step 4: Judge whether i≤n is established, if the judgement result is yes, go to step 5; if the judgement result is no, go to step 12.

[0042] Step 5: The current set of processes to be scheduled is O i .

[0043] Step 6: Use the dual dynamic long path sorting strategy to match O i The processes in the scheduling sequence are arranged.

[0044] Step 7: The second workshop selection strategy is O i Arrange workshop processing

[0045] Step 8: Arrange the target process O during pre-dispatch ix The earliest start time of processing is S ix , The required processing time is t ix .

[0046] Step 9: Determine whether there is ...

Embodiment 3

[0051] The above-mentioned dual-dynamic long-path two-shop comprehensive scheduling method uses a dual-dynamic long-path sorting strategy for descending scheduling for each layer of the process tree to be scheduled for the process set, that is, when scheduling comprehensively considers the equipment occupation caused by the scheduled process The impact of process delay scheduling on the process, and calculate the total path length based on this, and finally schedule in descending order.

[0052] In the above-mentioned dual dynamic long-path two-shop comprehensive scheduling method, after the pre-scheduling of the scheduled process at each layer of the process tree, the average delay strategy is applied, and the gap generated between process processing is used to make the equipment processing compact to realize the product Process as soon as possible.

[0053] The above-mentioned dual-dynamic long-path two-shop comprehensive scheduling method, in order to reduce the number of migrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com