Wiring harness plate assembly and battery module

A technology for board assemblies and battery packs, applied to battery pack components, circuits, electrical components, etc., can solve the problems of cumbersome assembly steps and high product defect rate, and achieve improved space utilization, high fault tolerance, and simplified structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

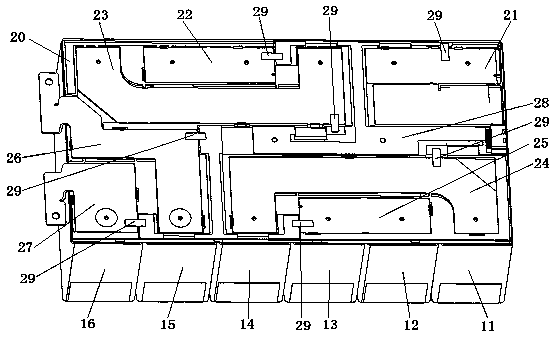

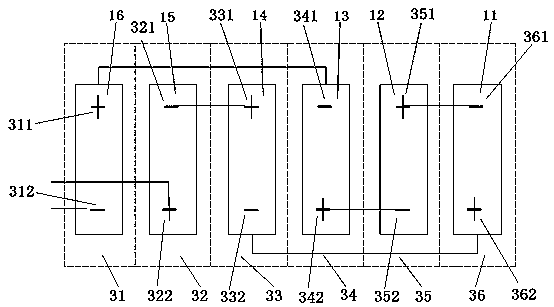

[0090] Embodiment 1 of the battery module in the present invention: the main components of the battery module are the battery pack and the wiring harness board assembly adapted to the battery pack, and the wiring harness board assembly covers the battery pack when used. Such as figure 1 As shown, the battery pack is composed of a plurality of single cells stacked, defining mutually perpendicular x and y directions. The positive electrode of one of the two single cells and the negative electrode of the other single cell are close to each other in the x direction and arranged along the y direction in a manner of "positive-negative, negative-positive, positive-negative...".

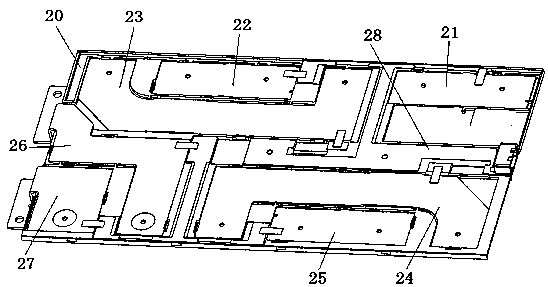

[0091]The wiring harness board assembly mainly includes a support plate 20 , a conductive sheet mounted on the support plate 20 and a printed board 28 mounted on the support plate 20 . Each part of the harness board assembly is now introduced separately.

[0092] Such as image 3 and Figure 5 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com