Intelligent power control wall breaking machine

A wall-breaking machine, intelligent power technology, applied in the field of wall-breaking machine, can solve the problem of low concentration

Inactive Publication Date: 2020-05-01

廖忠民

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Some of the existing wall-breaking machines have the function of food paste, and most models have a low concentration. For example, the amount of pure rice paste stipulated in the manual of a product of a certain brand is that when the water volume is 900-1100 ml, dry rice 1 / 2 cup; when the water volume is 1100-1300 ml, 4 / 5 cup of dry rice; 1 measuring cup of dry rice is about 100 grams, so the concentration of the food paste made by it is less than 8%, which is indeed relatively thin; and the food paste of suitable concentration For many users, such as the elderly with degenerated teeth, infants with incomplete teeth, and those with weak gastrointestinal functions, it is very necessary; the existing wall breaking machine cuts and pulverizes materials more finely, which is to increase the size of the motor. Power, increasing motor speed, changing tool shape, prolonging cutting time and other methods, these methods have improved some cutting and crushing effects, but the improvement of the effect is far from proportional to the increase of motor power, the increase of motor speed, and the extension of cutting time , also needs to be improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

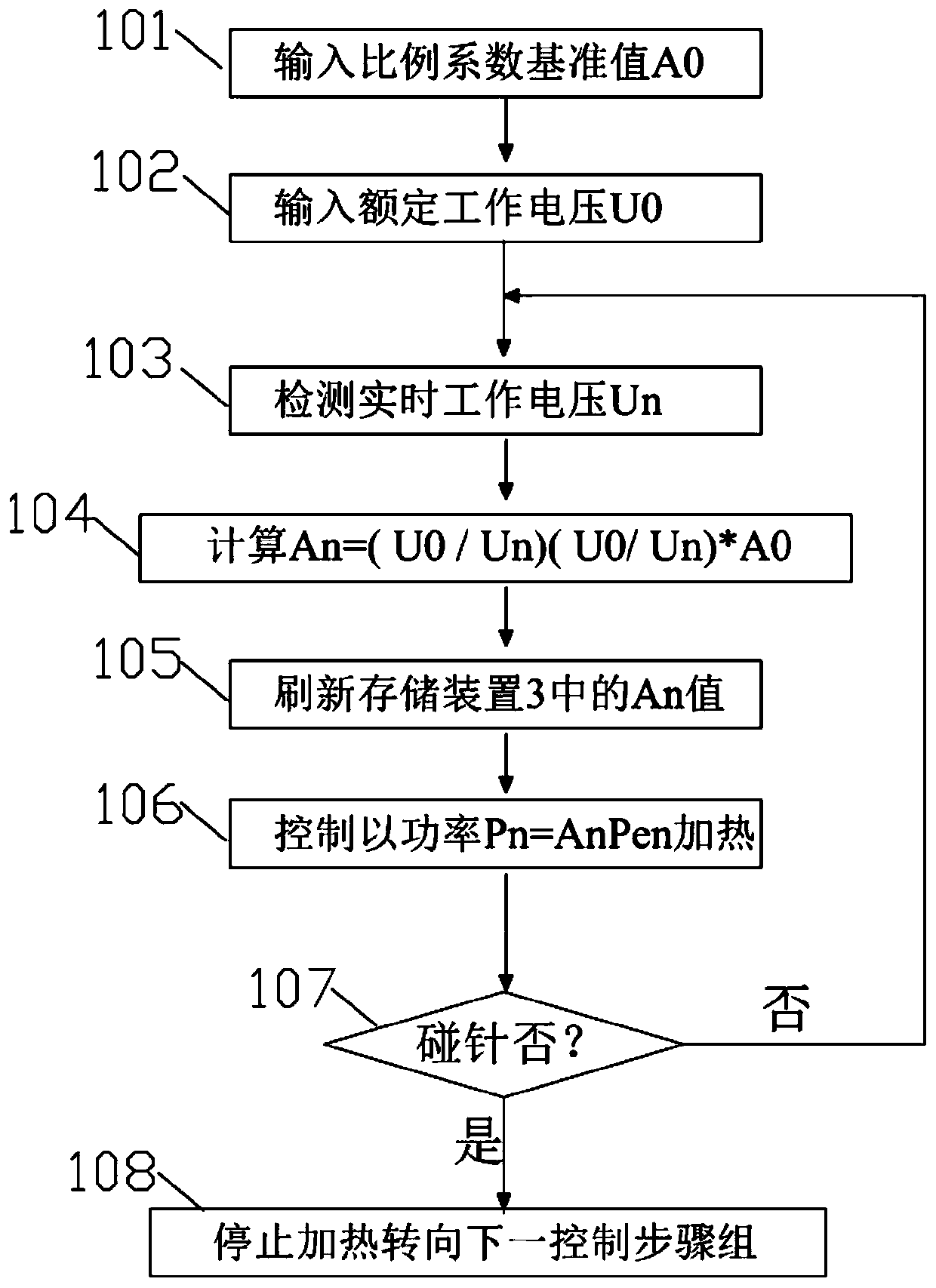

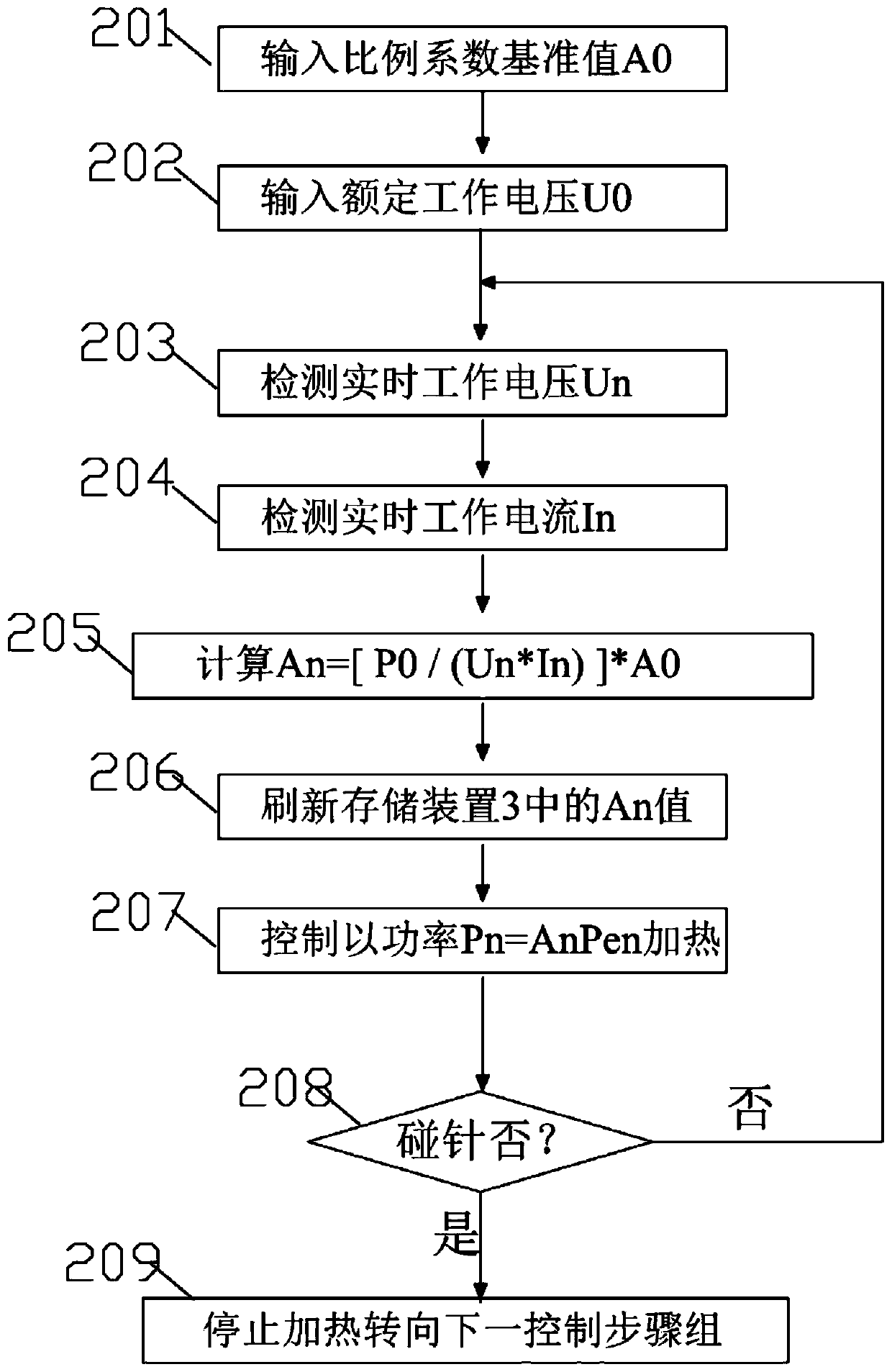

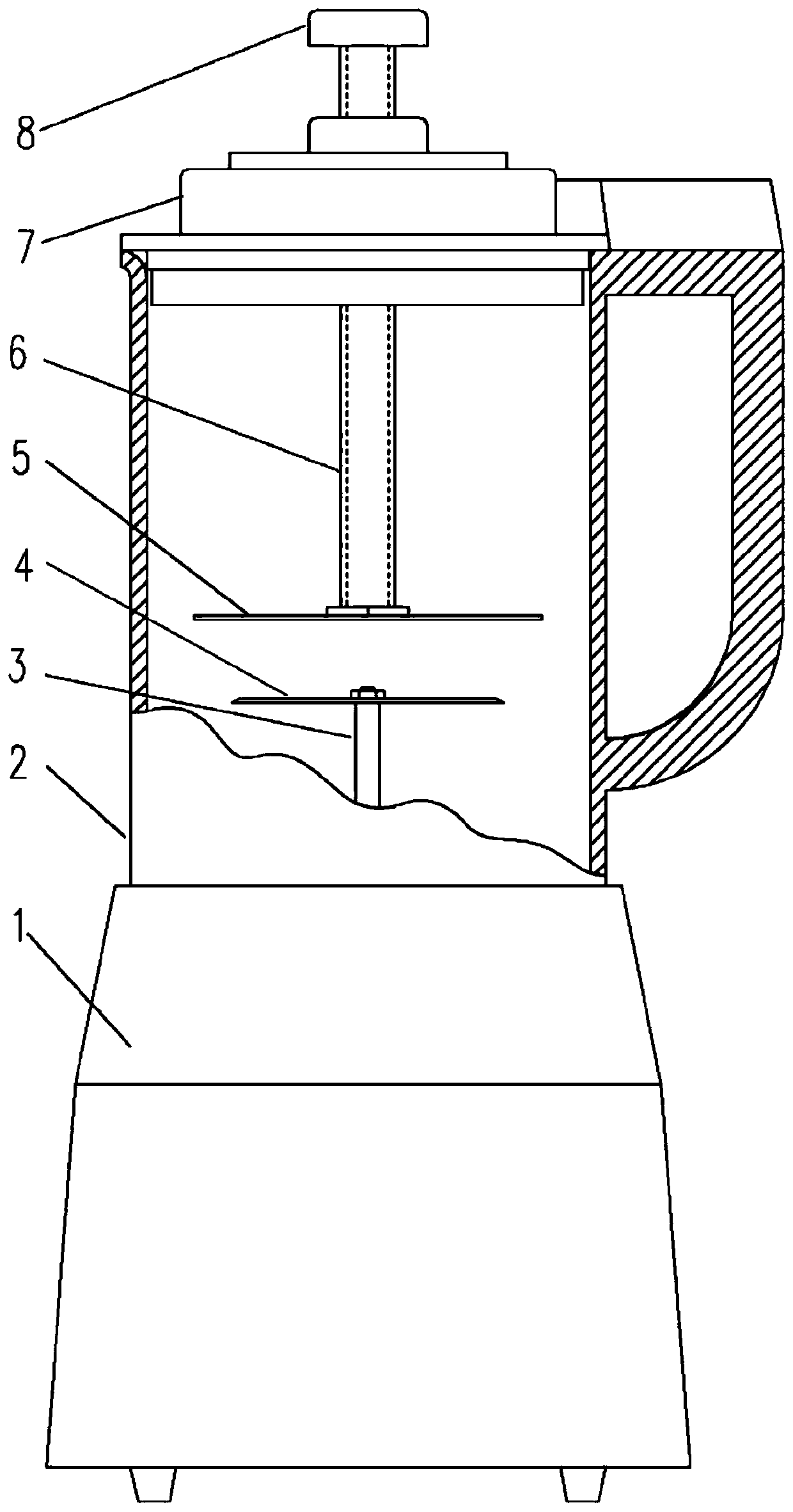

Login to View More Abstract

Provided is an intelligent power control wall breaking machine; an intelligent power control module A or an intelligent power control module B automatically adjusts the heating power and time to meetthe control requirements according to actually measured electrical parameters, so that the defect that high-concentration paste food is burnt or cannot be cooked can be avoided; according to a fine cutting device A, by arranging a reflector, the movement direction of part of material particles is changed from the direction away from a main cutting tool to the direction colliding with the main cutting tool, so that negative energy for weakening the cutting effect is converted into positive energy for enhancing the cutting effect; a second fine cutter or a third fine cutter converts negative energy for weakening the cutting effect into positive energy for enhancing the cutting effect by arranging two cutter sets with opposite cutting directions. The beneficial effects of saving energy and improving efficiency and quality are achieved.

Description

technical field [0001] The invention relates to the field of material processing equipment, in particular to a wall breaking machine. Background technique [0002] Some of the existing wall-breaking machines have the function of food paste, and most models have a low concentration. For example, the amount of pure rice paste stipulated in the manual of a product of a certain brand is that when the water volume is 900-1100 ml, dry rice 1 / 2 cup; when the water volume is 1100-1300 ml, 4 / 5 cup of dry rice; 1 measuring cup of dry rice is about 100 grams, so the concentration of the food paste made by it is less than 8%, which is indeed relatively thin; and the food paste of suitable concentration For many users, such as the elderly with degenerated teeth, infants with incomplete teeth, and those with weak gastrointestinal functions, it is very necessary; the existing wall breaking machine cuts and pulverizes materials more finely, which is to increase the size of the motor. Power...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A47J43/046A47J43/07

CPCA47J43/046A47J43/0716A47J43/0722A47J43/075

Inventor 廖忠民

Owner 廖忠民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com