Intelligent temperature control food processor

A food processing machine and temperature control technology, which is applied in the direction of timing control ignition mechanism, utensils with integral electric heating device, cooking utensils, etc., which can solve the problems of insufficient processing, large proportion, burning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

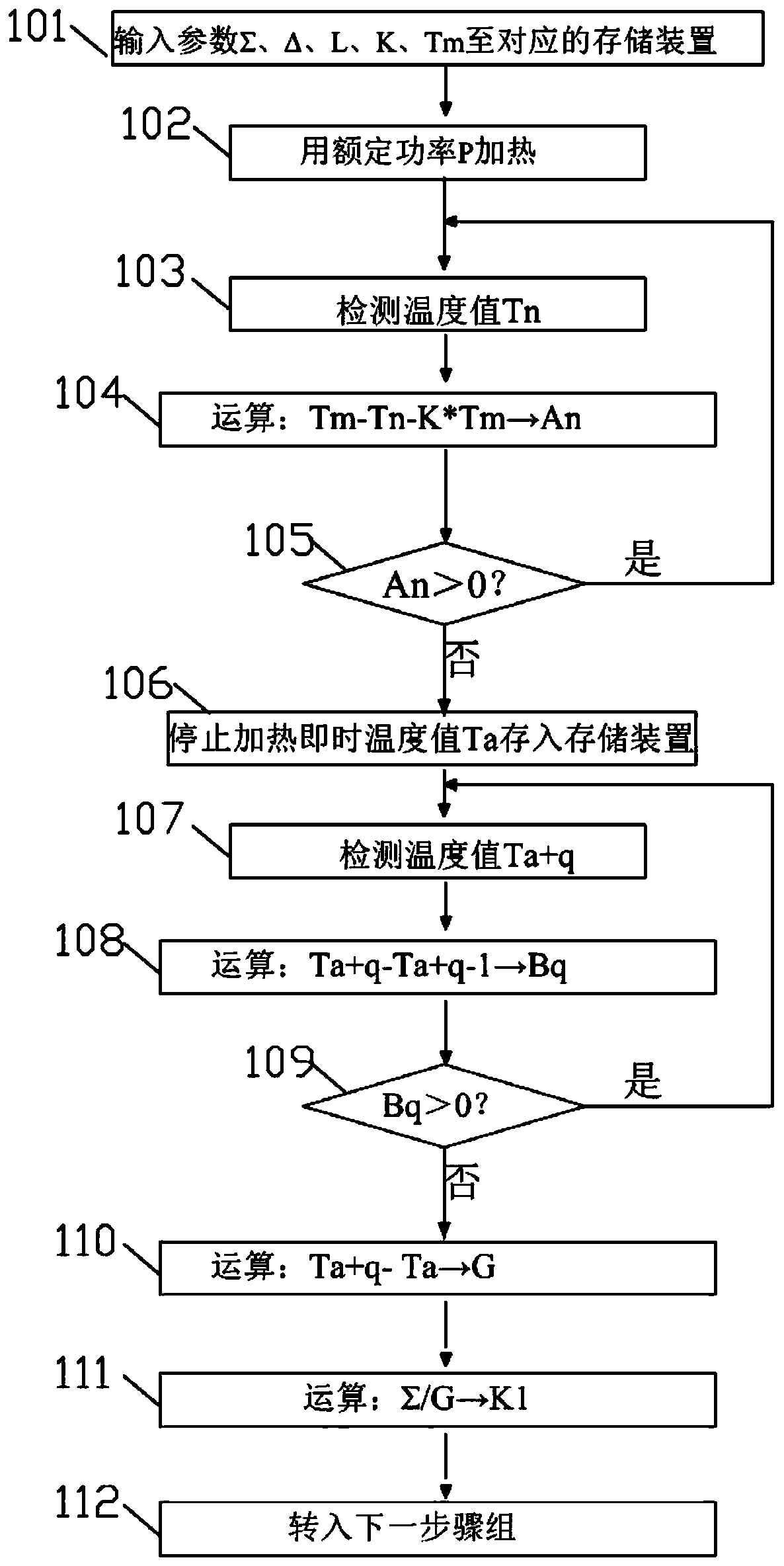

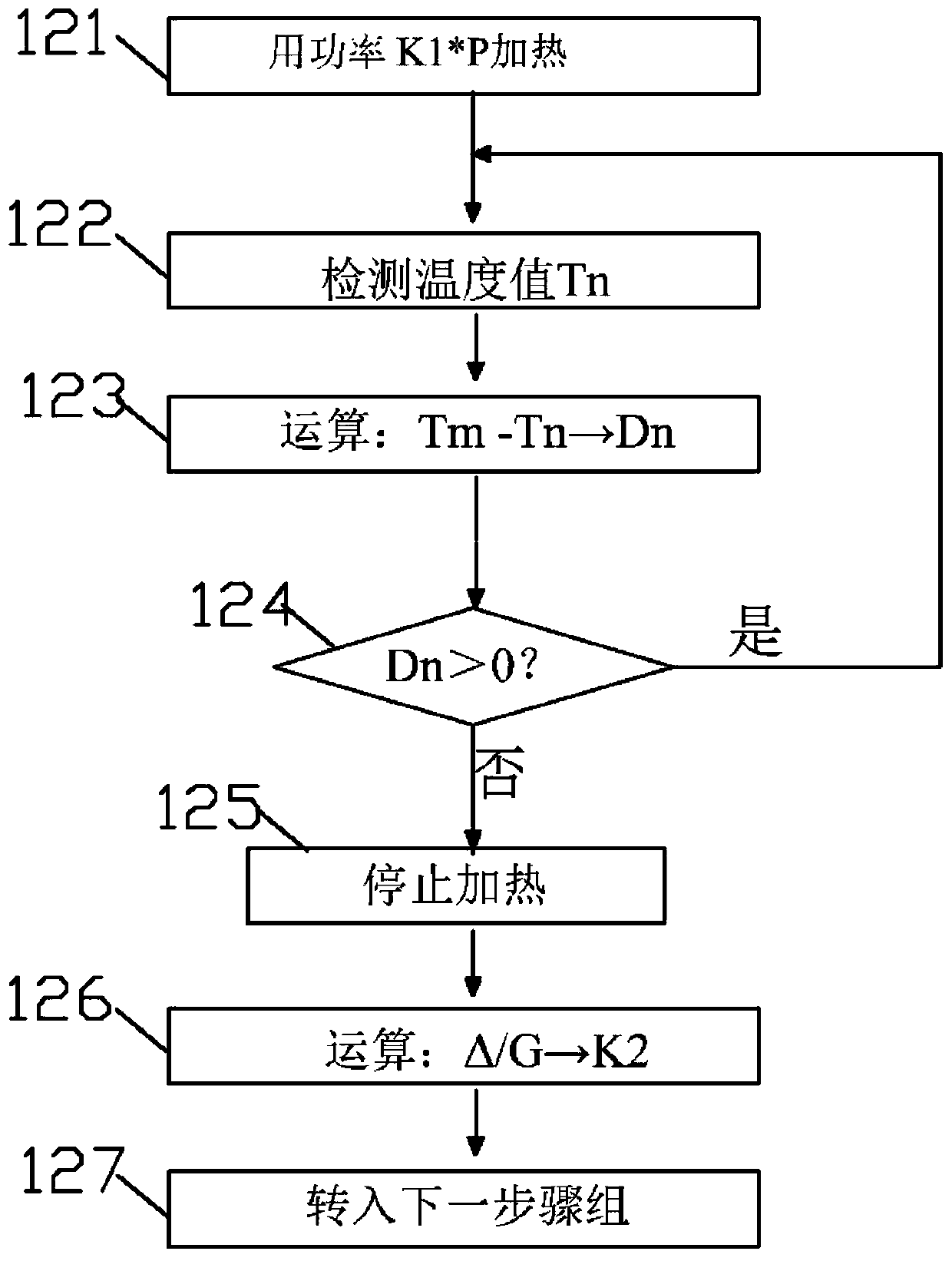

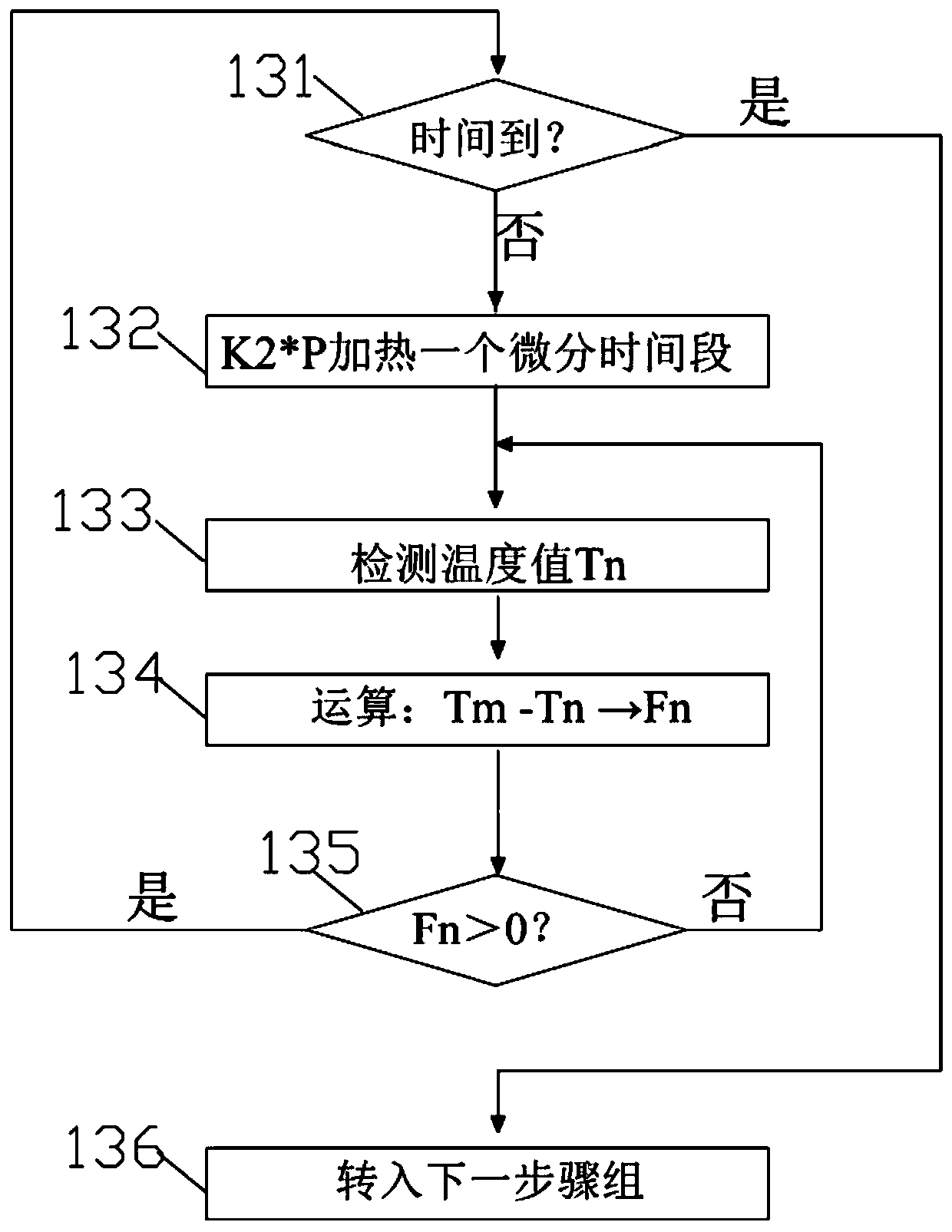

[0053] Example 1, figure 1 , figure 2 , image 3 It is also a schematic diagram of Example 1. The food paste processing program in the control program of the food processor was originally, step group 1, preheating: heating for 6 minutes and stopping for 2 seconds, if there is a touch needle in the middle (the liquid level foam touches the anti-overflow needle) ), then stop heating for 2 seconds and go to the next program; step group 2, pre-cutting: the motor runs for 20 seconds and stops for 6 seconds; step group 3, continue heating until the needle touches for 20 seconds, touch the needle twice and go to the next program Program; step group 4, main cutting: the motor runs for 35 seconds and stops for 10 seconds, cycle 3 times; step group 5, boiling: heat for 3 seconds and stop for 7 seconds, if there is a needle touch in the middle, stop for 20 seconds, after 10 cycles The motor runs for 10 seconds and stops for 6 seconds; after step group 6 and step group 5 circulate 13 t...

Embodiment 2

[0123] Example 2, Figure 1 ~ Figure 3 It is also a schematic diagram of Example 2. The food paste processing program in the control program of the processing machine was originally, step group 1, preheating: heating for 6 minutes and stopping for 2 seconds, if there is a needle touch in the middle, stop heating for 2 seconds and then switch to Next program; step group 2, pre-cutting: the motor turns for 20 seconds and stops for 5 seconds, then turns to the next step group; step group 3, continues heating until the needle touches and stops for 20 seconds, then turns to the next step group; step group 4, relay Cutting: the motor turns for 35 seconds and stops for 10 seconds, then turns to the next step group; step group 5, initial cooking: heats for 3 seconds, stops for 8 seconds, touches the needle, stops for 20 seconds, cycles 2 times, turns to the next step group; step group 6. Main cutting, the motor rotates for 25 seconds and stops for 5 seconds to cycle 4 times, and then ...

Embodiment 3

[0124] Embodiment 3, a kind of processing machine that adopts fine grinder first; image 3 Also be the schematic diagram of embodiment 3, the structure of fine grinder first and working principle see [0011] paragraph, [0012] paragraph described; Reflector 33 cooperates with main cutting tool 31, strengthens cutting effect; When whole device according to main The rotation axis of the cutting tool 31 is placed in a vertical direction, and when the component force of the main cutting tool 31 parallel to the direction of the rotation axis is vertically upward, the reflector is arranged above the main cutting tool 31, and the machine head 34 Below; the shaft 32 of the main cutting tool passes through the reflector 33 and is connected with the main cutting tool 31, and the cooperation between the shaft 32 of the main cutting tool and the reflector 33 is a moving fit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com