Intelligent temperature control wall breaking machine

A temperature control and intelligent temperature control technology, applied in the field of wall breakers, which can solve problems such as low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

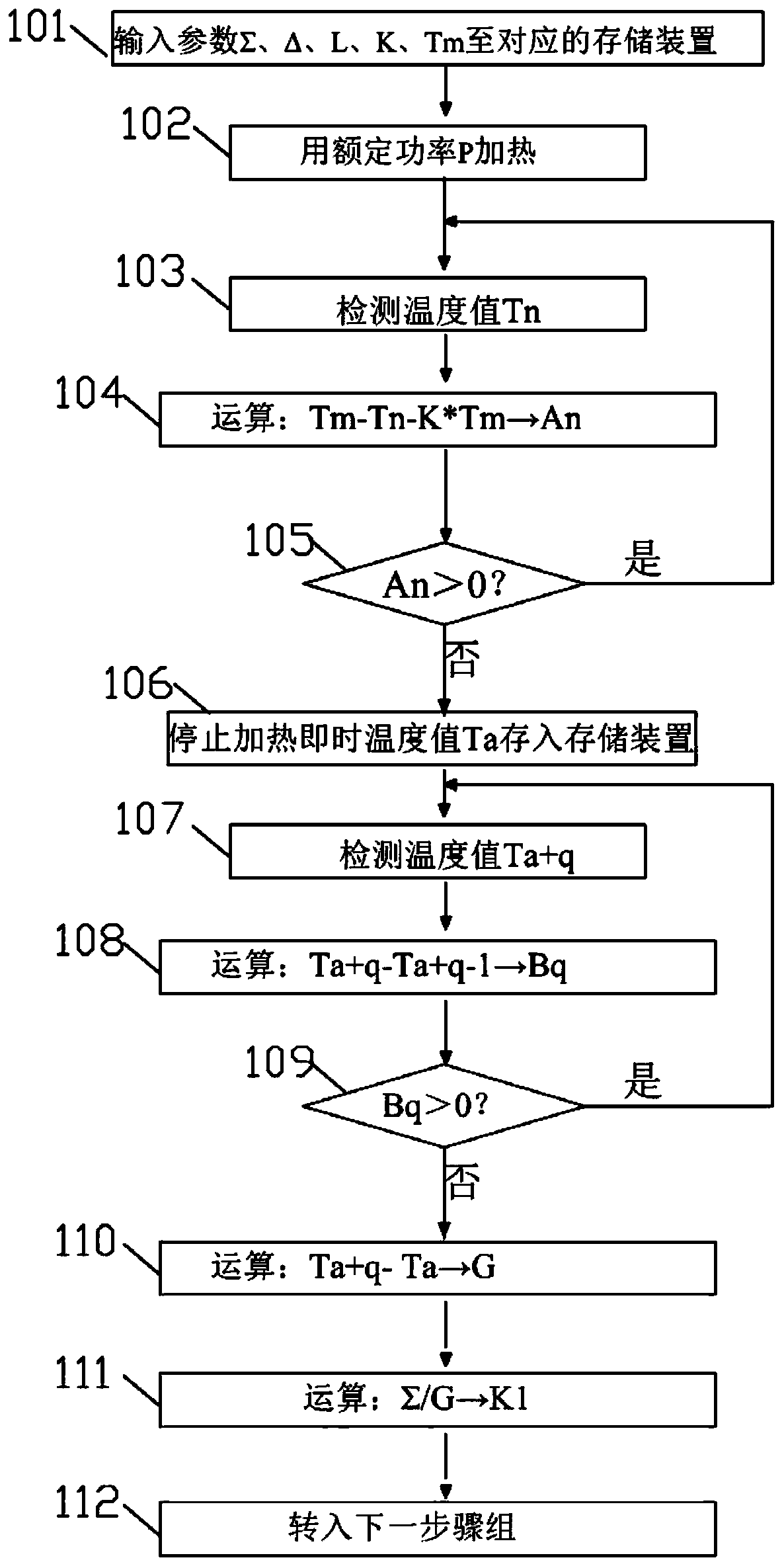

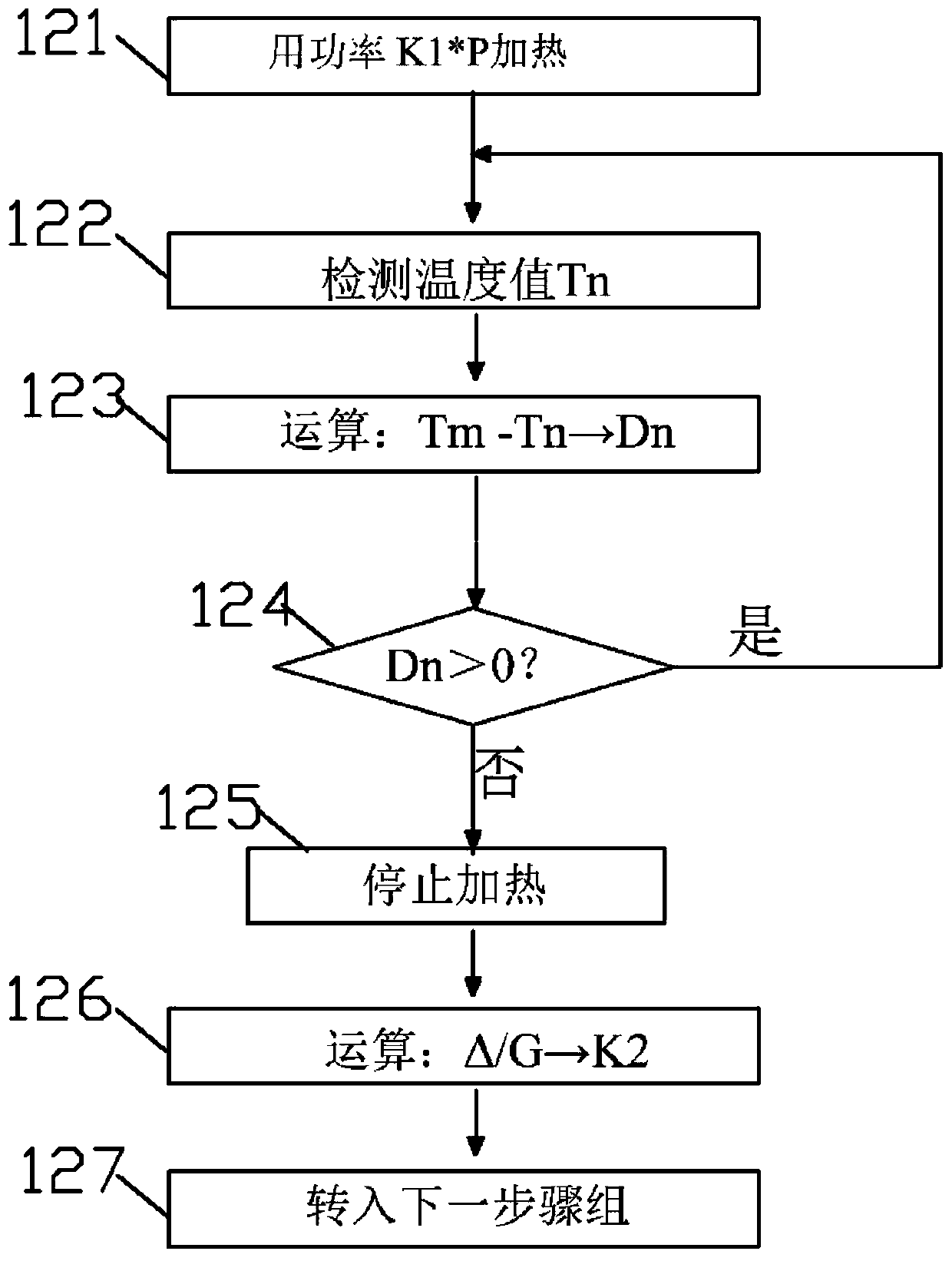

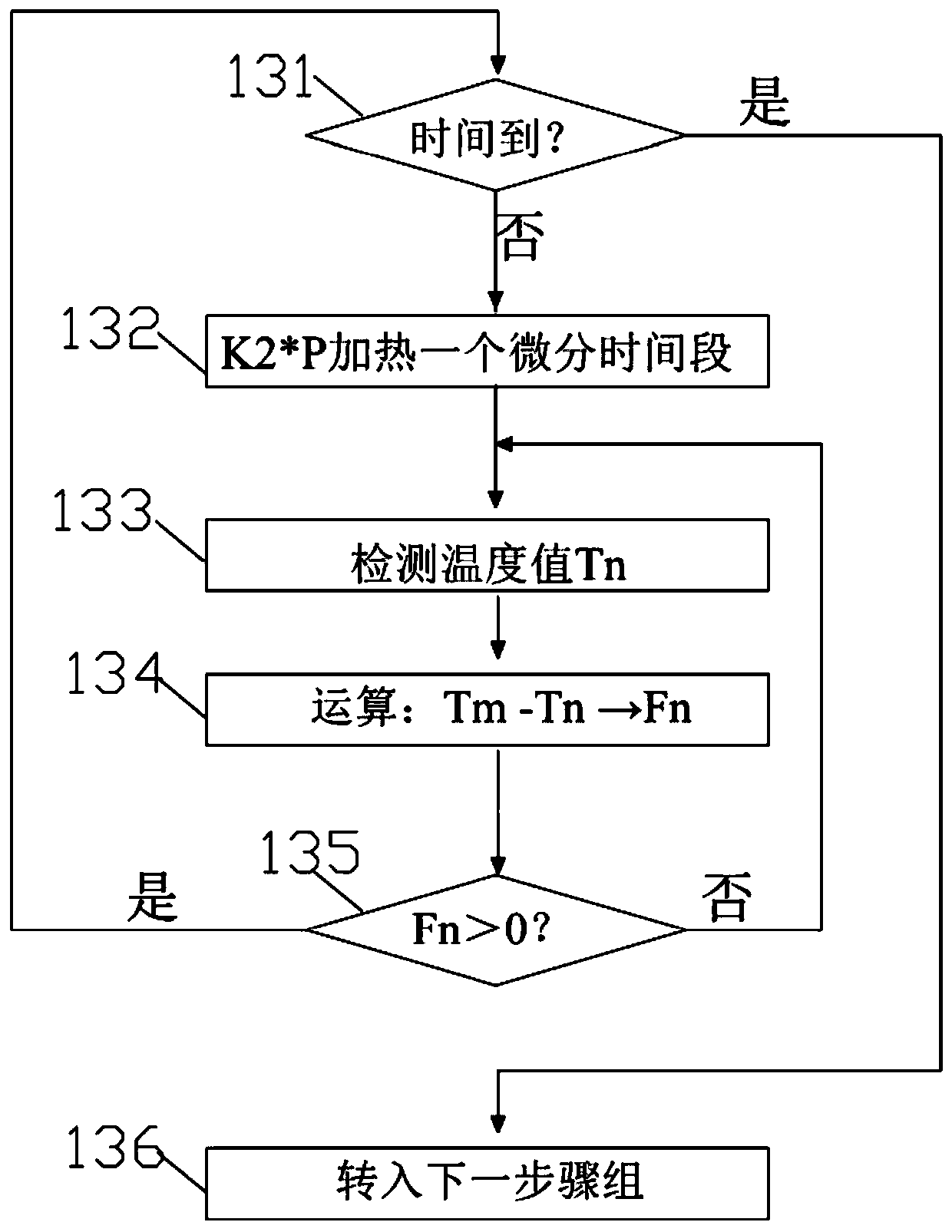

[0051] Example 1, figure 1 , figure 2 , image 3 It is also a schematic diagram of Example 1. The food paste processing program in the control program of the broken wall machine originally included, step group 1, preheating: heating for 6 minutes and stopping for 2 seconds, if there is a touch pin in the middle (the liquid level foam contacts the anti-overflow needle), then stop heating for 2 seconds and then transfer to the next program; step group 2, pre-cutting: the motor rotates for 20 seconds and stops for 6 seconds; step group 3, continue heating until the needle touches the needle for 20 seconds, touch the needle twice and transfer to the next program One program; step group 4, main cutting: the motor rotates for 35 seconds and stops for 10 seconds, cycle 3 times; step group 5, boiling: heat for 3 seconds and stop for 7 seconds, if there is a needle touch in the middle, stop for 20 seconds, 10 cycles After that, the motor turns for 10 seconds and stops for 6 seconds;...

Embodiment 2

[0121] Example 2, Figure 1 ~ Figure 3 It is also a schematic diagram of Example 2. The food paste processing program in the control program of the broken wall machine was originally, step group 1, preheating: heating for 6 minutes and stopping for 2 seconds, if there is a needle touch in the middle, stop heating for 2 seconds and then turn on Enter the next program; step group 2, pre-cutting: the motor turns for 20 seconds and stops for 5 seconds, then turns to the next step group; step group 3, continues heating until the needle touches and stops for 20 seconds, then turns to the next step group; step group 4, middle Continue cutting: the motor turns for 35 seconds and stops for 10 seconds, then turns to the next step group; step group 5, initial boiling: heat for 3 seconds and stop for 8 seconds, touch the needle, stop for 20 seconds, cycle 2 times, turn to the next step group; step Group 6, main cutting, the motor rotates for 25 seconds and stops for 5 seconds to cycle 4 t...

Embodiment 3

[0122] Example 3, Figure 4 Also be the schematic diagram of embodiment 2, the structure of fine cutter first and working principle see [0010] paragraph, [0011] paragraph described; Reflective disk 5 cooperates with main cutting tool 4, strengthens cutting effect; When whole device according to main The rotation axis of the cutting tool 4 is placed in the vertical direction, and when the component force of the main cutting tool 4 parallel to the direction of the rotation axis is vertically upward, the reflective disk 5 is arranged above the main cutting tool 4; the reflective disk 5 is supported by a pillar 6, and its height is adjustable, and the height is adjustable, including or the pillar 6 is a screw rod, which cooperates with a nut installed inside the container cover 7, and is adjusted by rotating the adjustment cap 8 at the top of the pillar 6, and the adjustment cap The shape is either made into a polygon, or the outer circumference is knurled, or a hole is made, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com