Fine processing and intelligent power control food processing cooking machine

A technology of food processing and fine processing, which can be used in home appliances, applications, kitchen utensils, etc., and can solve the problems of low concentration of food paste, burning, and insufficient processing

Inactive Publication Date: 2020-04-24

廖忠民

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Food paste food is the food that people often need to eat in life, and some equipment with food paste processing function have appeared in food processing equipment, such as soybean milk machine with nutrition paste function; but the existing food paste processing function For processing machines, the proportion of water in the ratio of ingredients stipulated in the instructions is extremely large, and the processed food paste has a low concentration. When the total amount of various ingredients does not exceed 1 measuring cup), and the water must be between the upper and lower water lines (the capacity reaching the lower water line is 1100 ml, and the capacity reaching the upper water line is 1300 ml); another example is a big brand According to the instructions of a product from China, the amount of pure rice paste is 1 / 2 cup of dry rice when the water volume is 900-1100 ml, and 4 / 5 cup of dry rice when the water volume is 1100-1300 ml; this concentration is not enough for many eaters. It is indeed too thin; but if the machine user wants to increase the concentration and add more dry ingredients when making the paste, it may cause the food to burn; therefore, many users hope to have a household appliance that can produce a higher concentration of food paste; At the same time, the processing of food materials by existing food processors is not fine enough, and many users hope that there will be household appliances that can produce finer-grained food materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

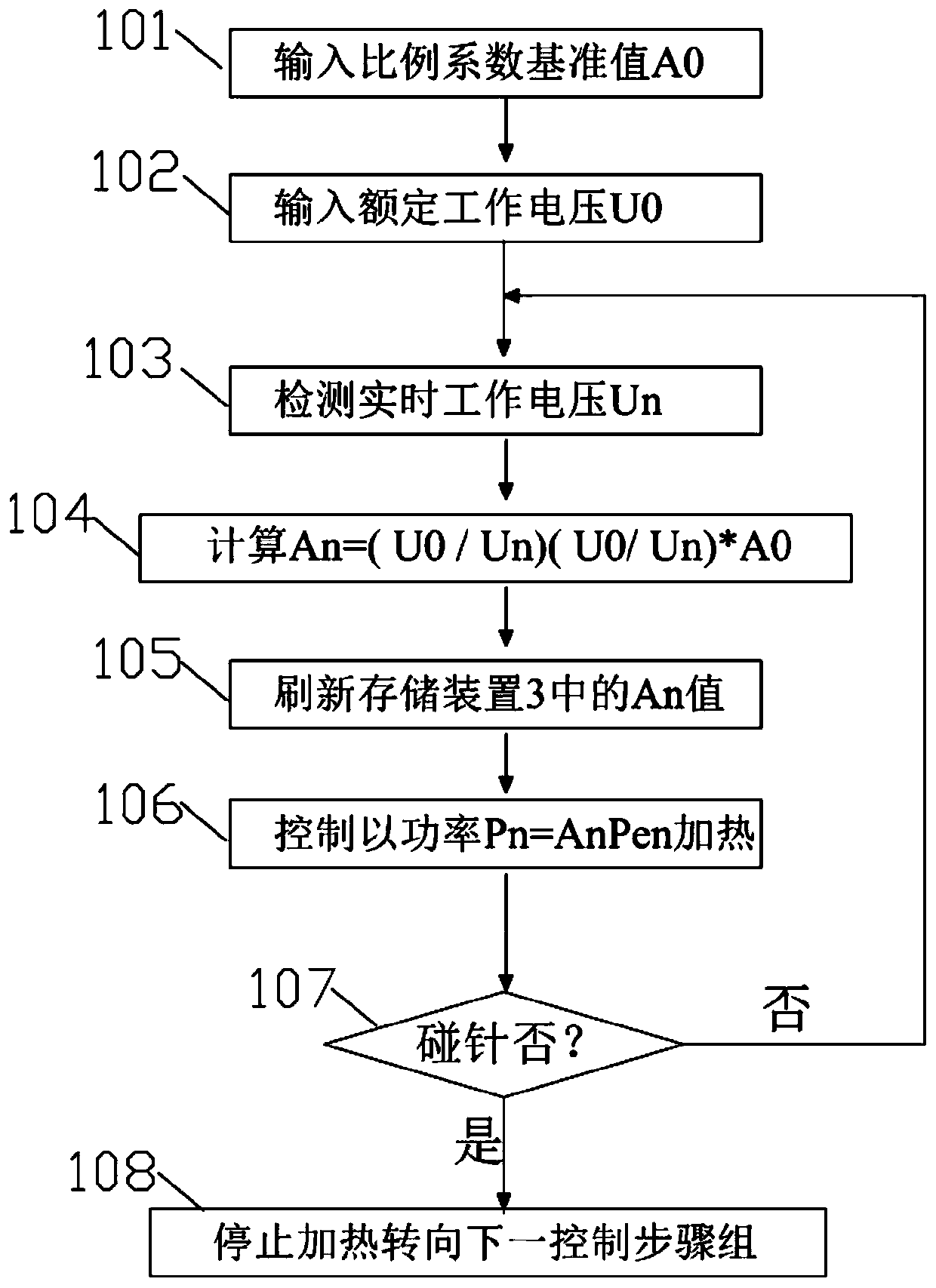

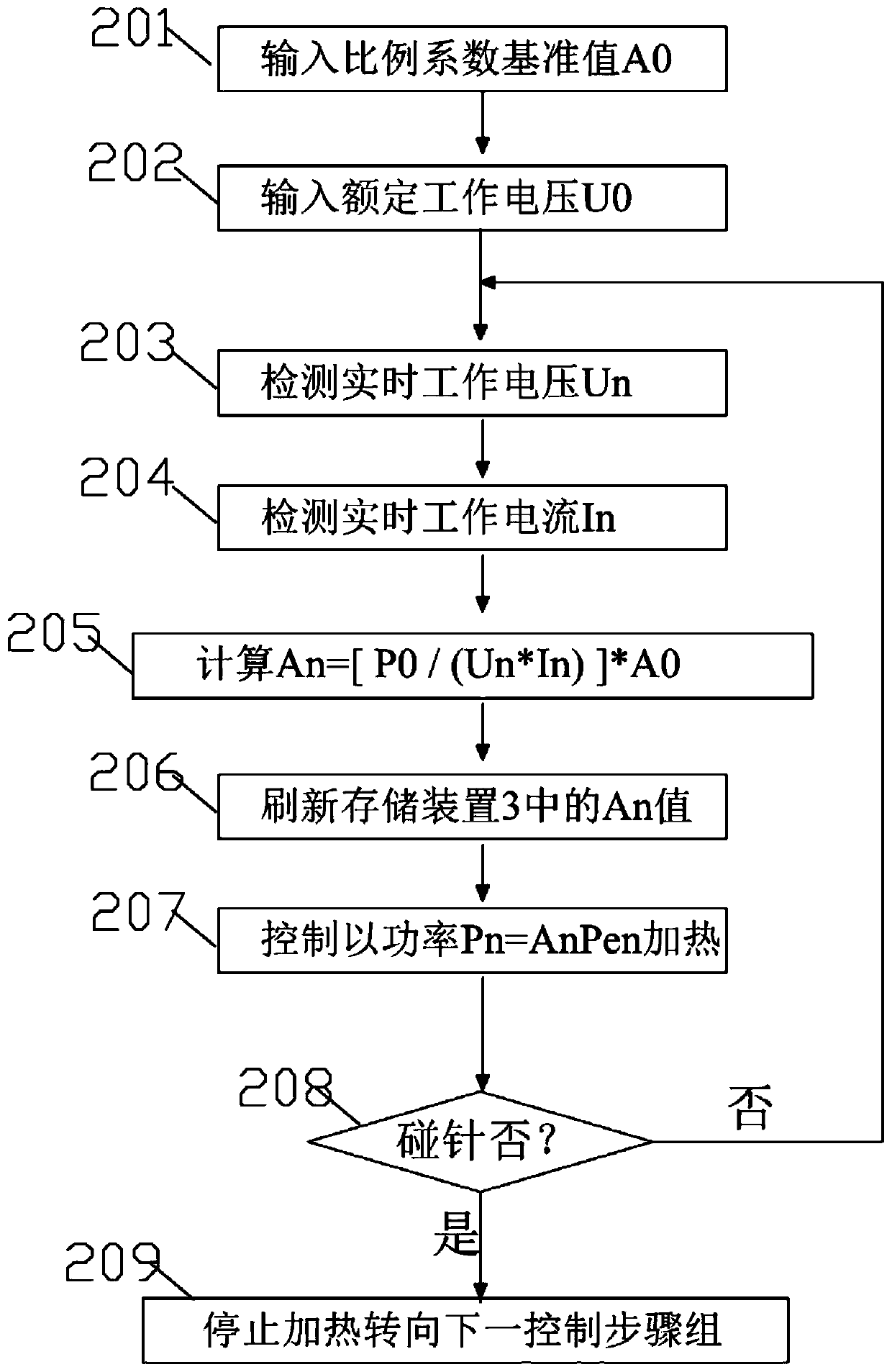

Login to View More Abstract

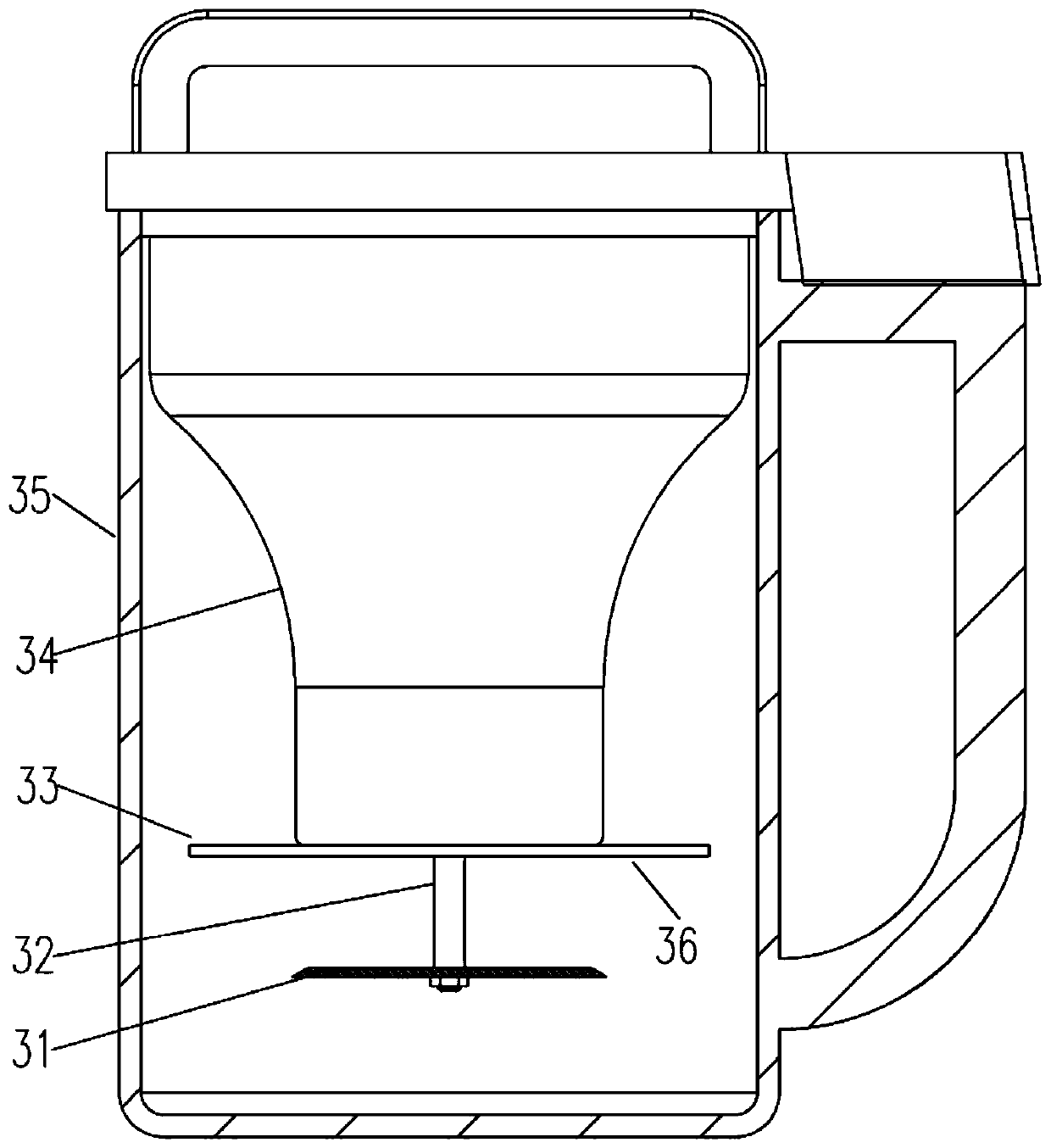

The invention relates to a fine processing and intelligent power control food processing cooking machine. An intelligent power control module A or an intelligent power control module B automatically adjusts the heating power to meet the control requirement according to actually measured electrical parameters, and the defect that high-concentration paste food is burnt or cannot be cooked thoroughlycan be avoided; a fine grinder A, by arranging a reflector, changes the movement direction of part of material particles from a direction away from a main cutting tool to the direction colliding withthe main cutting tool, so that negative energy for weakening the cutting effect is converted into positive energy for enhancing the cutting effect; and a fine grinder B is used for converting the negative energy for weakening the cutting effect into the positive energy for enhancing the cutting effect by arranging two groups of cutter groups with opposite cutting directions; and the beneficial effects of saving energy and improving efficiency and quality are achieved.

Description

technical field [0001] The invention relates to the field of food processing equipment, in particular to a food processing and cooking machine. Background technique [0002] Food paste food is the food that people often need to eat in life, and some equipment with food paste processing function have appeared in food processing equipment, such as soybean milk machine with nutrition paste function; but the existing food paste processing function For processing machines, the proportion of water in the ratio of ingredients stipulated in the instructions is extremely large, and the processed food paste has a low concentration. When the total amount of various ingredients does not exceed 1 measuring cup), and the water must be between the upper and lower water lines (the capacity reaching the lower water line is 1100 ml, and the capacity reaching the upper water line is 1300 ml); another example is a big brand According to the instructions of a product from China, the amount of p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47J43/044A47J43/07A47J43/08

CPCA47J43/044A47J43/0705A47J43/0711A47J43/082A47J2201/00A47J2202/00A47J2203/00

Inventor 廖忠民

Owner 廖忠民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com