Optimized sensing food processing cooking machine

A technology of food processing and cooking machines, which can be used in home appliances, applications, kitchen utensils, etc. It can solve the problems of low concentration of food paste, can only be set on the edge of the container, and the accuracy of temperature control is not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

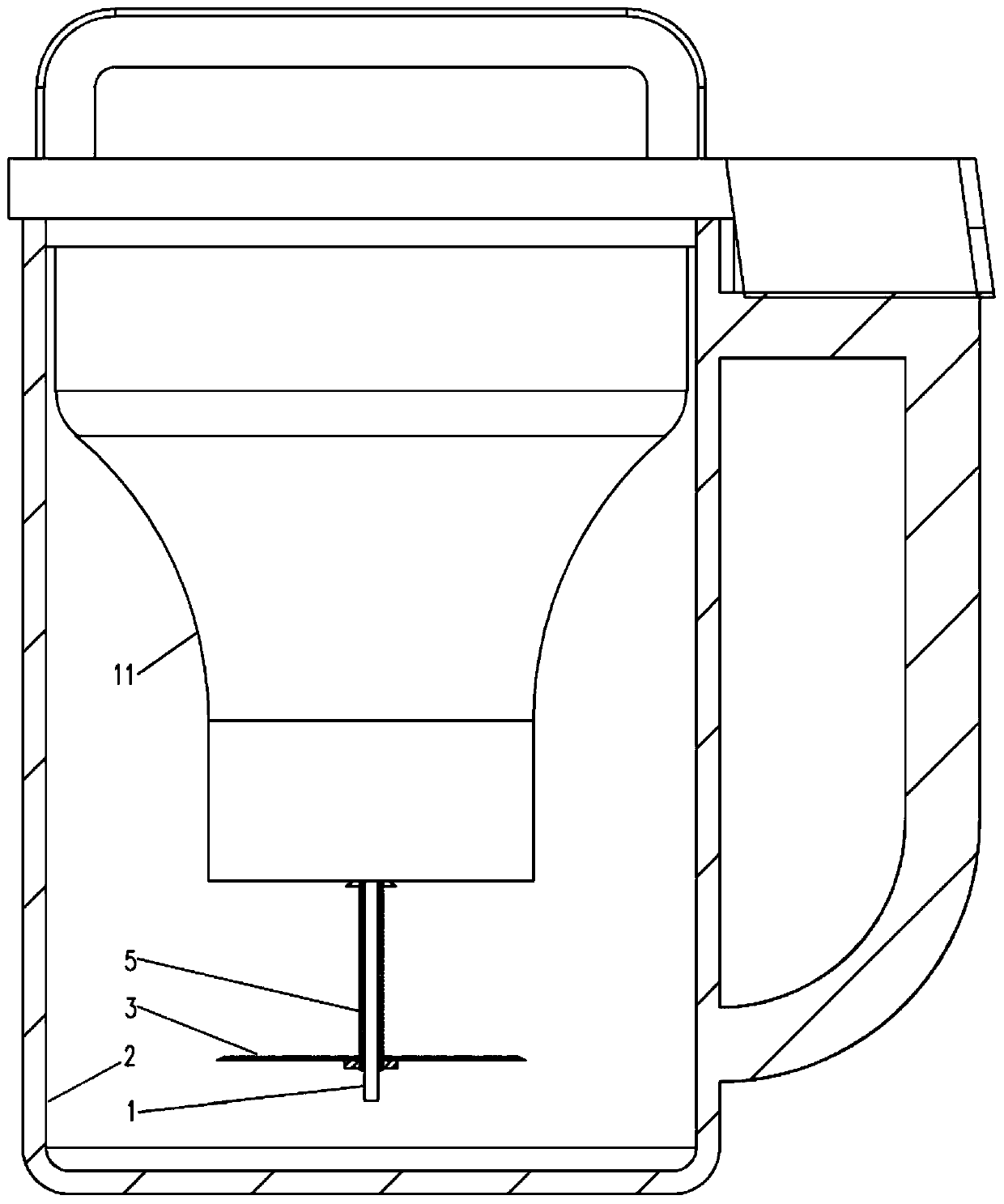

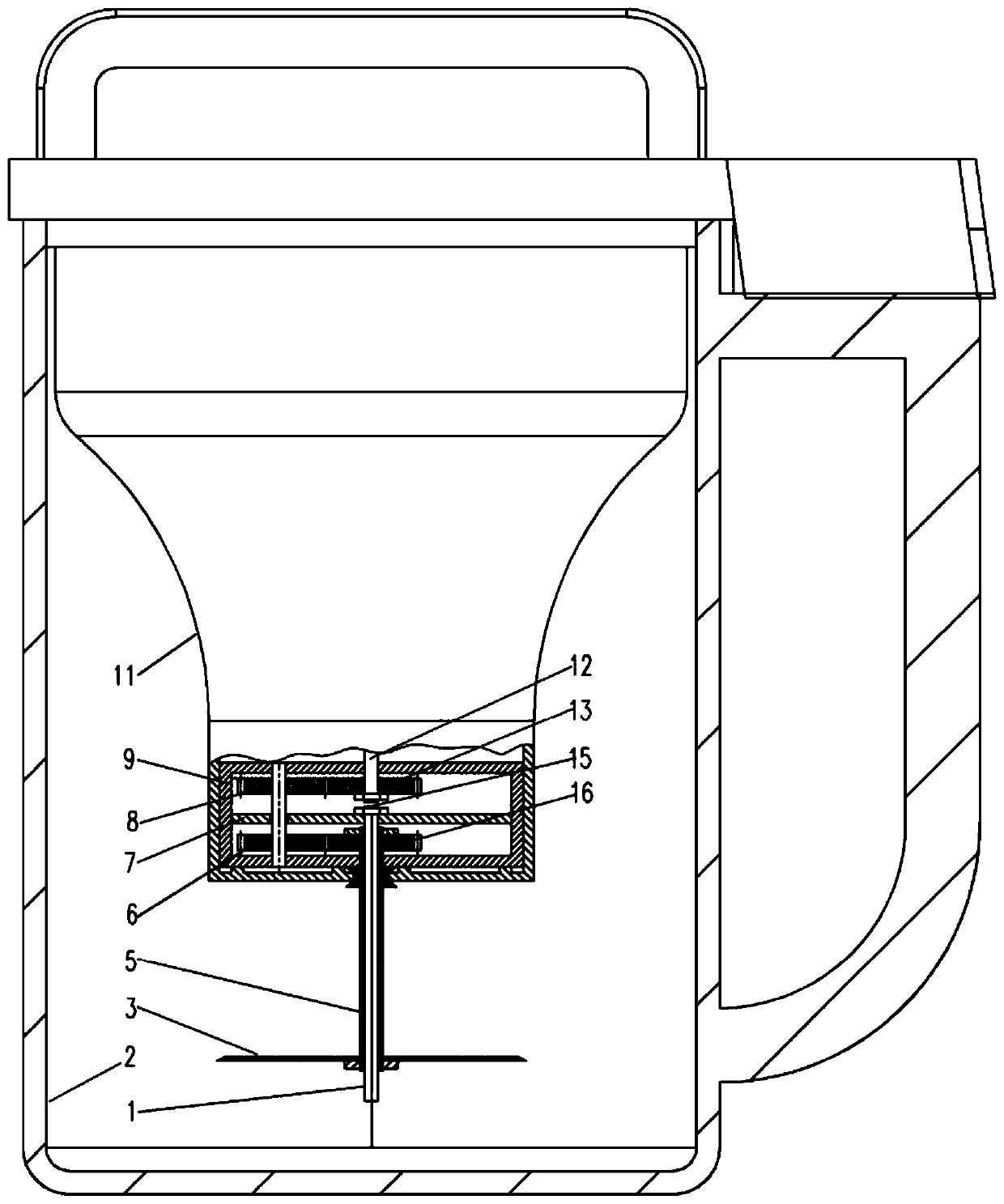

[0061] Embodiment 1, an optimized sensing food processing and cooking machine equipped with a central temperature sensor; figure 1 , figure 2 Also be the schematic diagram of embodiment 1, its structure and working principle see paragraph [0004], paragraph [0005] and figure 1 , figure 2The power main shaft 12 in the machine head is coaxially fixedly connected with the driving gear 13, the upper transmission gear 8 is coaxially fixedly connected with the lower transmission gear 6, the cutter group 3 of the cutting device, the shaft 5 of the cutting device and the shaft gear of the cutting device 16 are coaxially fixedly connected, and the central temperature sensor passes through the channel in the middle of the shaft 5 of the cutting device to extend the probe part to the bottom of the central area of the container 2; the transmission steps of the power transmission from the machine head to the cutter set 3 of the cutting device include, The power main shaft 12 in the ma...

Embodiment 2

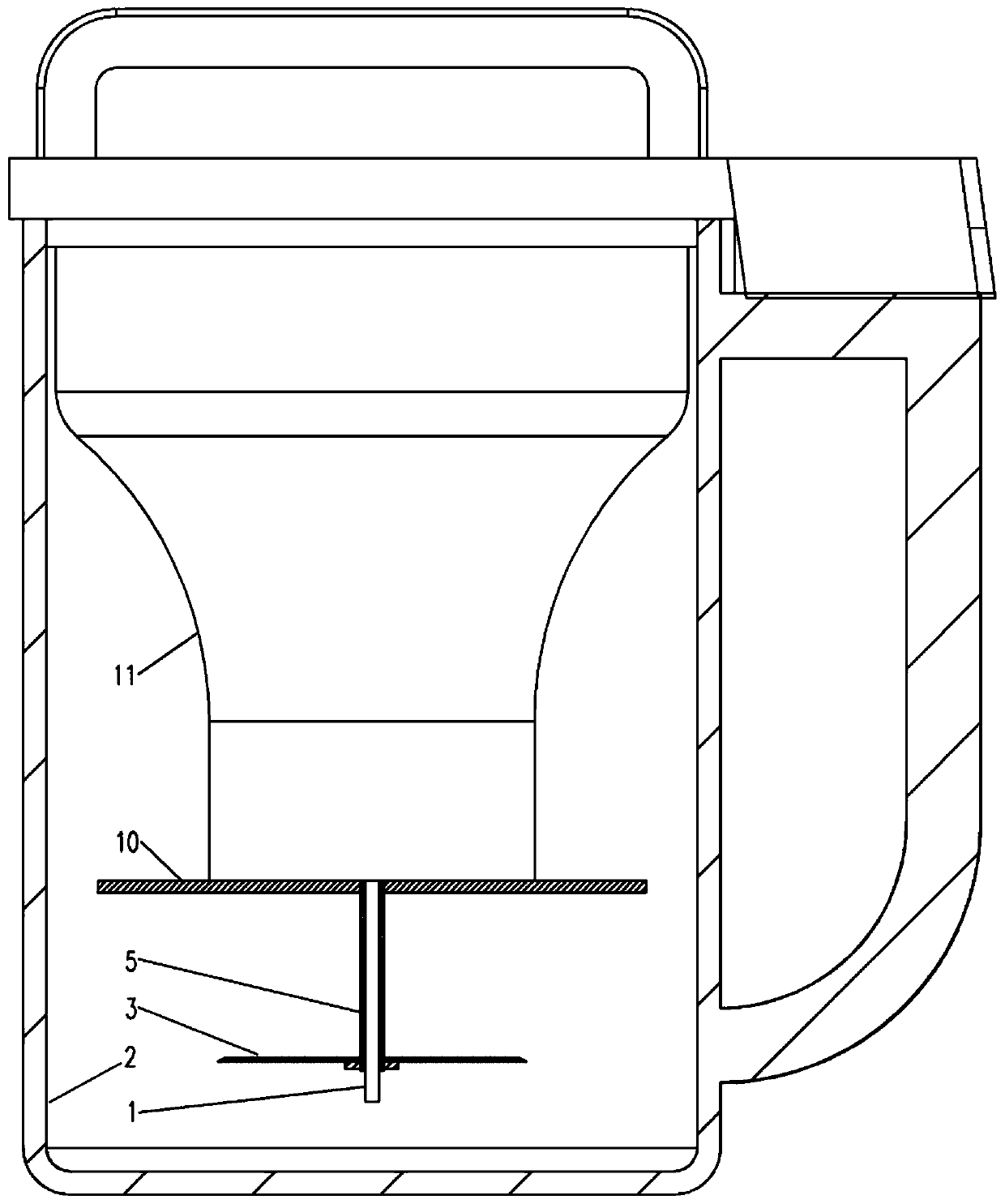

[0062] Embodiment 2, an optimized sensor food processing and cooking machine configured with a reflective fine cutter; image 3 Also be the schematic diagram of embodiment 2, its structure and working principle see paragraph [0004], paragraph [0006] and image 3 Said; the reflector 10 cooperates with the cutter set 3 of the cutting device to enhance the cutting effect; when the whole device is placed in the vertical direction according to the rotation axis of the cutter set 3 of the cutting device, and the cutter set 3 of the cutting device is placed in the When the component force parallel to the direction of the axis of rotation is vertically upward, the reflector is arranged above the cutter set 3 of the cutting device and below the machine head 11; the shaft 5 of the cutting device passes through the reflector 10 and the cutter set of the cutting device 3 connection, the cooperation between the shaft 5 of the cutting device and the reflector 10 is a dynamic fit; the centra...

Embodiment 3

[0063] Embodiment 3, an optimized sensor food processing and cooking machine configured with a hedge type fine cutter; Figure 4 Also be the schematic diagram of embodiment 2, its structure and working principle see paragraph [0004], paragraph [0008] and Figure 4 Described; The described hedging type fine cutter, its cutting tool is a cutter combination that includes two sets of cutting tools with opposite cutting directions; The two groups of cutting tools with opposite cutting directions are composed of a main cutting tool group and a secondary cutting tool group , the cutting direction of the main tool group and the auxiliary tool group are opposite; the tool group not only exerts a circumferential and tangential force on the material during the rotating cutting process, but also through the slope of the blade, or the bending angle of the blade or other The structural method produces a component force parallel to the direction of the rotation axis on the material; among th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com