Design method for die chain of coarse specification steel wire drawn by double low-power car frame

A design method and low-power technology, which is applied in the field of mold chain design for drawing thick-gauge steel wires with double low-power lathes, can solve problems such as less power sharing, inability to produce, and fewer mold sequences, so as to improve drawing quality and reduce The effect of equipment purchase cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

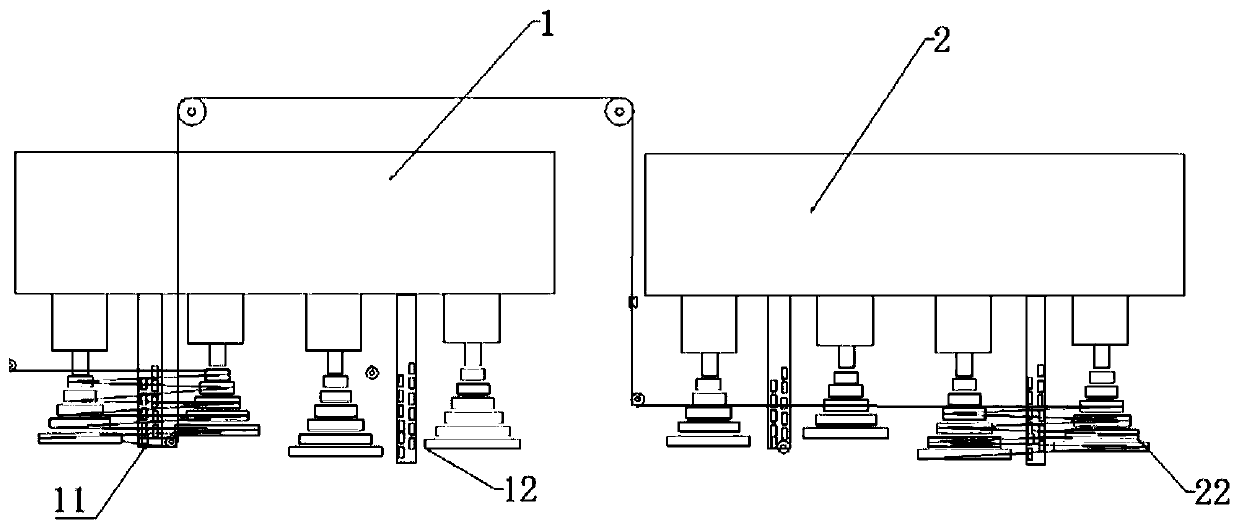

[0021] The invention discloses a mold chain design method for drawing thick-gauge steel wires with double low-power lathes, such as figure 1 Shown: including the following steps:

[0022] 1) The use of the platform is a double platform design of the first platform 1 and the second platform 2, wherein the first platform 1 includes the first cone wheel set 11 on the left side and the second cone wheel set 12 on the right side ; The second vehicle platform 2 includes the third tower wheel group 21 and the fourth tower wheel group 22 arranged on the left side; the first tower wheel group 11 is arranged according to the direction of the steel wire to the right and left, and the left and right directions are successively provided with a total of 10 towers L1 ~ L10 According to the direction of the steel wire, the second tower wheel group 12 is arranged in right and left according to the direction of the steel wire. A total of 12 tower wheels L11 to L22 are arranged in the left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com