Electromagnetic heating flanging mold

A flanging mold, electromagnetic technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low heating efficiency, high temperature at the production site, long preheating time, etc., and achieve the effect of high heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

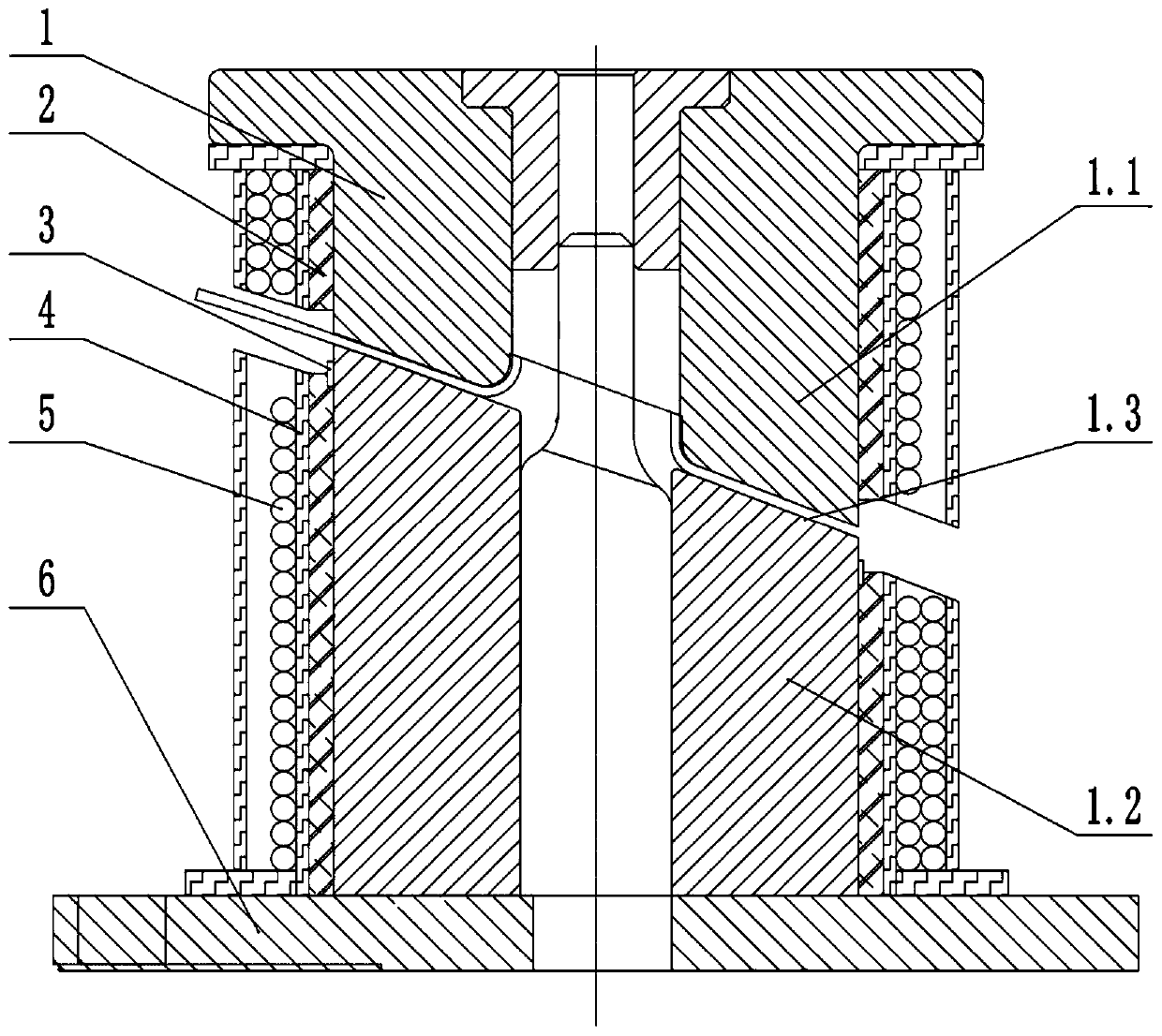

[0022] An electromagnetic heating flanging mold, comprising a mold main body 1, glass fiber cotton 2, fiber hard board 4 and high temperature resistant wire 5, the mold main body 1 is divided into an upper mold 1.1 on the upper part and a lower mold 1.2 on the lower part, and the outside of the mold main body 1 Wrap the glass fiber cotton 2 for heat insulation. The outside of the glass fiber cotton 2 is provided with a heat-resistant fiber hard board 4 that plays a supporting role. The fiber hard board 4 provides attachment for the heat-resistant high-temperature wire 5 . Winding high temperature resistant wire 5 coils, high temperature resistant wire 5 is mica wire, working temperature is 1000°C, upper mold 1.1 and lower mold 1.2 respectively wind a high temperature resistant wire 5, upper mold 1.1 winds high temperature resistant wire 5 and lower mold 1.2 The high-temperature-resistant electric wire 5 wound on the top is connected in series to the power supply, and two temper...

Embodiment 2

[0029] An electromagnetic heating flanging mold, comprising a mold main body 1, glass fiber cotton 2, fiber hard board 4 and high temperature resistant wire 5, the mold main body 1 is divided into an upper mold 1.1 on the upper part and a lower mold 1.2 on the lower part, and the outside of the mold main body 1 Wrap the glass fiber cotton 2 for heat insulation. The outside of the glass fiber cotton 2 is provided with a heat-resistant fiber hard board 4 that plays a supporting role. The fiber hard board 4 provides attachment for the heat-resistant high-temperature wire 5 . Winding high temperature resistant wire 5 coils, high temperature resistant wire 5 is mica wire, working temperature is 1000°C, upper mold 1.1 and lower mold 1.2 respectively wind a high temperature resistant wire 5, upper mold 1.1 winds high temperature resistant wire 5 and lower mold 1.2 The high-temperature-resistant electric wire 5 wound on the top is connected in series to the power supply, and two temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com