Solid waste compact treatment system and method by vibration, negative pressure and thermalization technology

A solid waste and treatment system technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of not properly collected and processed polluted gas, prone to rebound, and difficult to compact, achieve good compaction effect, reduce hardness, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

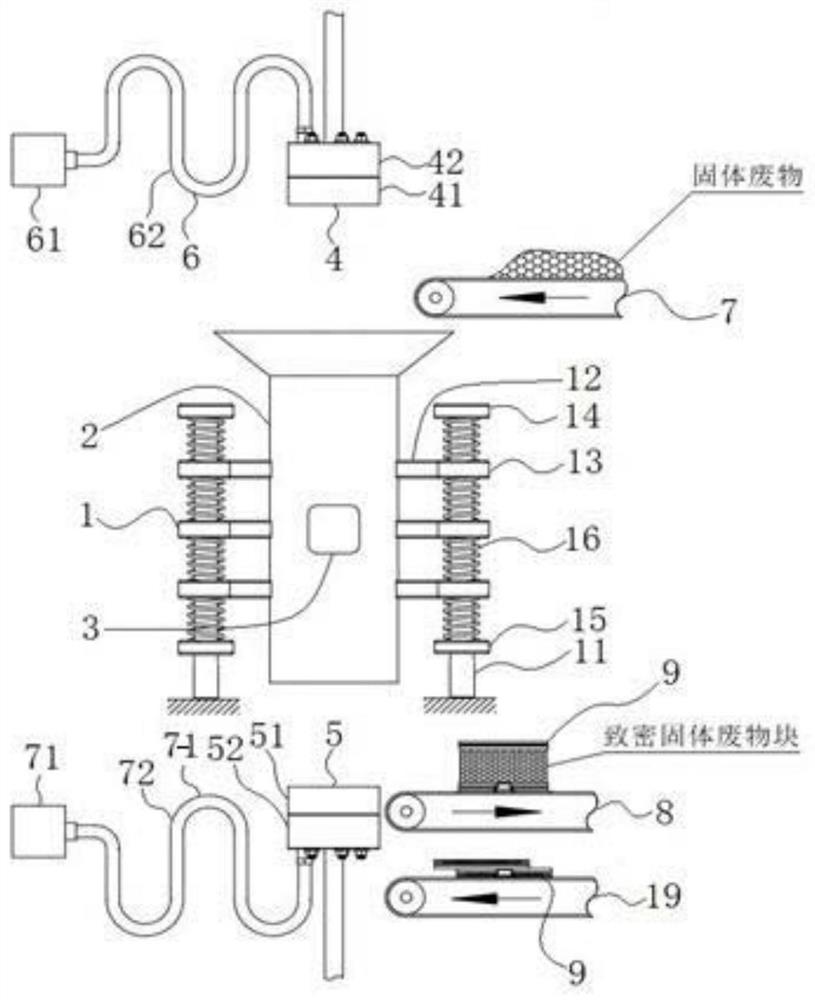

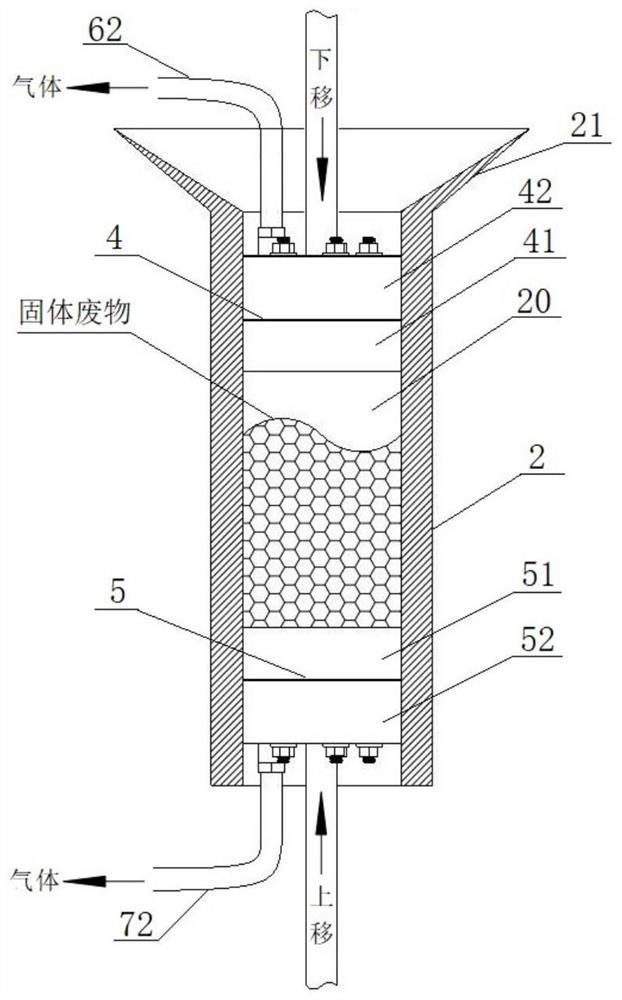

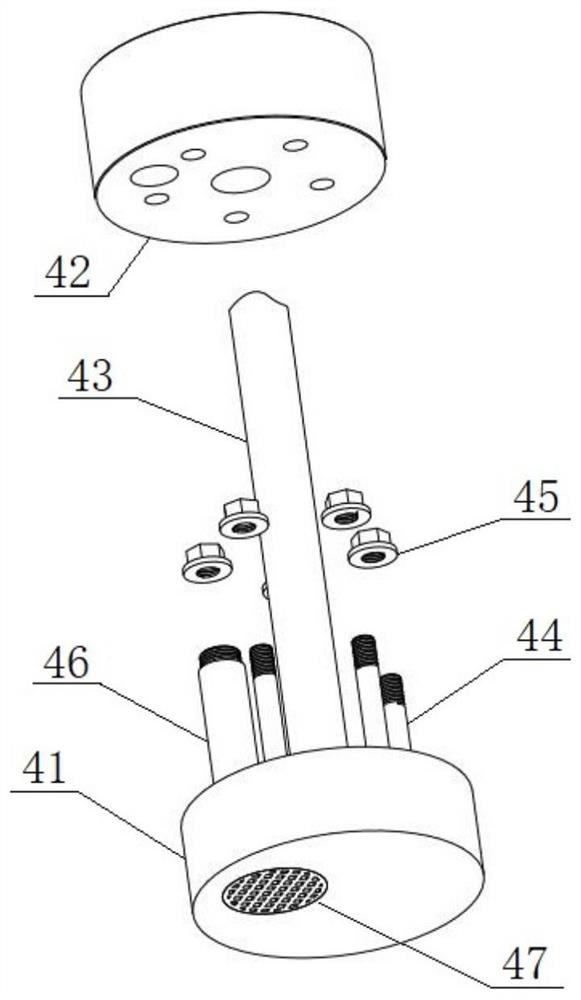

[0046] as attached figure 1 And attached figure 2 As shown, the solid waste densification treatment system of vibration, negative pressure and heating technology includes an elastic support frame 1 and a microwave heating container 2; To the suspension posture, and a vibrator 3 is installed outside it. The microwave heating container 2 can distribute the solid waste in the vibrating state from top to bottom from light to heavy, which is more conducive to its subsequent compaction operation, and avoids the phenomenon that the center of gravity of the formed dense solid waste block is biased upward, so that The dense solid waste block is placed more stably, and it does not need to be turned over to avoid loosening of the dense solid waste block, which is more conducive to subsequent handling, storage, transportation, etc.

[0047] It also includes a sliding sealing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com