Prestress press with double winding structures

A prestressing and press technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as impact, achieve the effects of reducing manufacturing processing, good fatigue resistance, and solving large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

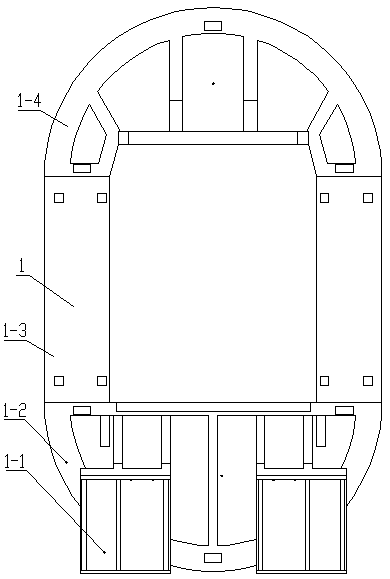

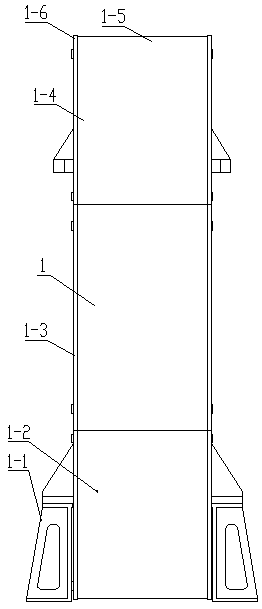

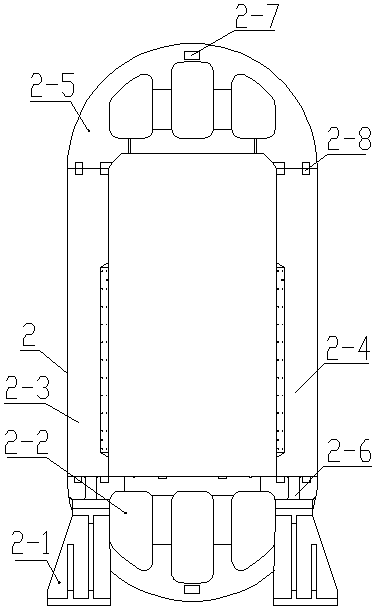

[0019] see image 3 , Figure 4 , the present embodiment is a prestressed press machine with a double winding structure, which is composed of a front frame 2, a rear frame 3, a left beam 4 and a right beam, the front frame 2 and the rear frame 3 are arranged side by side, and the front frame The frame 2 and the rear frame 3 are welded and connected by the horizontal left beam 4 and the right beam (not shown in the figure). The front frame 2 and the rear frame 3 have the same structure. The rear ear seat 3-2, the rear lower semicircular beam 3-3, the rear left column 3-4, the rear upper semicircular beam 3-5, the rear oil cylinder platform 3-6 and the rear right column (not shown in the figure), the front The frame 2 and the rear frame 3 constitute a hollow box-shaped structure.

[0020] Front frame 2 is made of front base 2-1, front lower semi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap