Oil-electric hybrid electric vehicle, control method, computer equipment and readable storage medium

An oil-electric hybrid power and control method technology, applied in the automotive field, can solve problems such as broken gearboxes, inability to directly switch oil drive systems, and failure of oil drive systems to start from first gear, etc., to achieve a good driving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

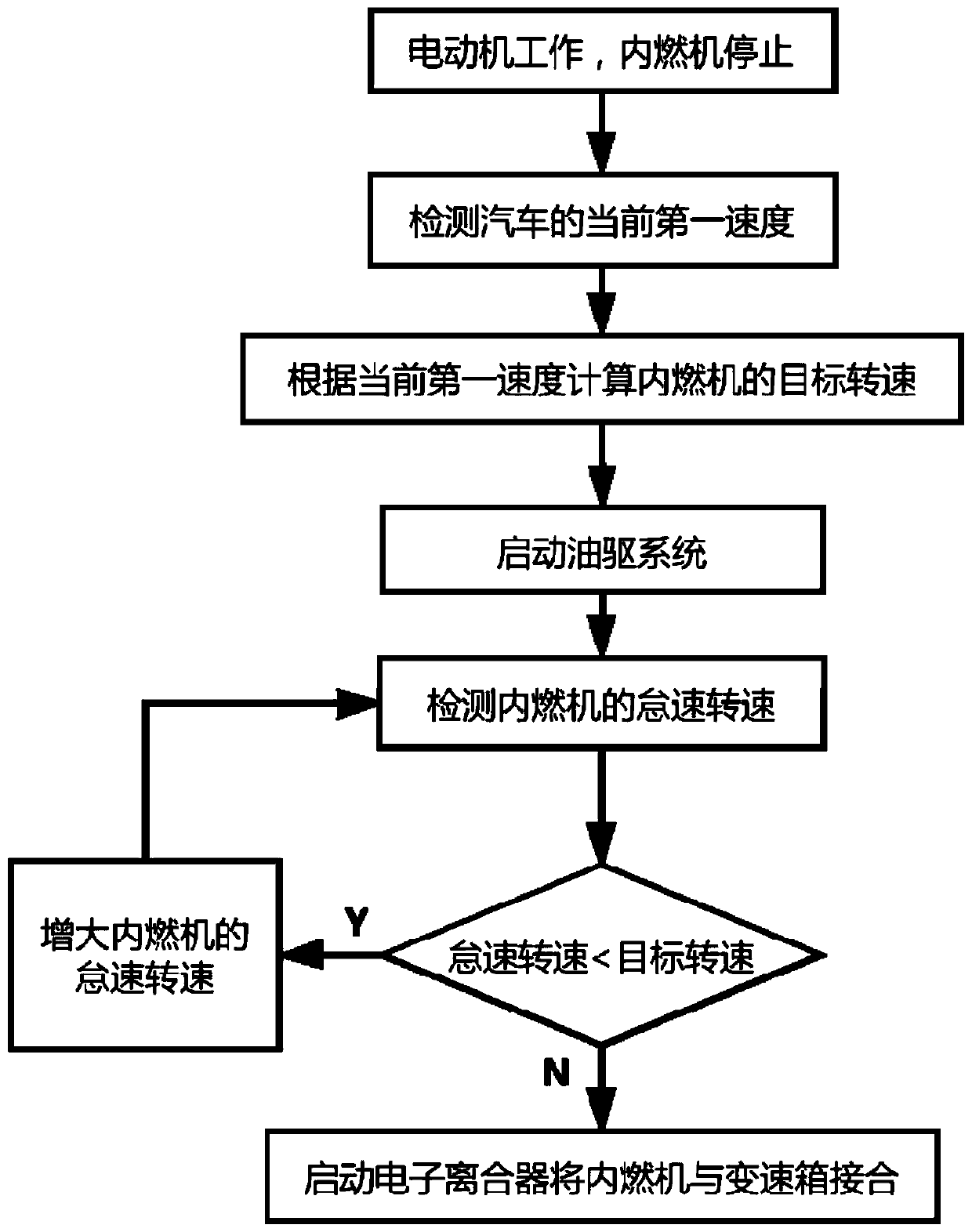

Method used

Image

Examples

Embodiment 1

[0059] In this embodiment, the step of "detecting the current first speed of the vehicle, and calculating the target speed that the internal combustion engine of the oil drive system needs to output according to the current first speed" further includes: detecting the speed of the electric drive system the current motor speed of the motor, the current motor speed being the current first speed;

[0060] calculating the target rotational speed required to be output by the internal combustion engine of the oil flooding system according to a first preset formula;

[0061] The first preset formula is

[0062] N 2 =N 1 G 2 / G 1

[0063] Among them, N 1 is the current motor speed, N 2 is the target speed, G 1 is the reduction ratio of the electric drive system, G 2 is the reduction ratio of the oil drive system.

[0064] It is based on the principle that when the electric drive system is working, there is a corresponding relationship between the motor and the vehicle speed ...

Embodiment 2

[0074] In this embodiment, the step of "detecting the current first speed of the vehicle, and calculating the target speed that the internal combustion engine of the oil drive system needs to output according to the current first speed" further includes:

[0075] Detecting the current motor speed of the motor of the electric drive system, converting the current vehicle speed according to the current motor speed, the current vehicle speed being the current first speed;

[0076] adjusting the reduction ratio of the oil flooding system according to the current first speed;

[0077] According to the reduction ratio of the oil drive system, setting the target speed range that the internal combustion engine of the oil drive system needs to output;

[0078] Any value in the target speed range can be set as the target speed.

[0079] In this embodiment, the detected current first speed is the current vehicle speed of the car. According to the above description, it may also be convert...

Embodiment 3

[0085] Further, it also includes the step of reducing the power of the electric drive system after the internal combustion engine is engaged with the gearbox.

[0086] Furthermore, the step of "reducing the power of the electric drive system after the internal combustion engine is engaged with the gearbox" further includes:

[0087] the internal combustion engine engages the transmission;

[0088] detecting a current second speed of the vehicle;

[0089] When the set vehicle speed remains unchanged, the power of the electric drive system is adjusted until the electric drive system is turned off or the current second speed is equal to the current first speed.

[0090] The followability of the electric drive system is higher than that of the oil drive system. Followability refers to the time period from when an operation command is issued to the oil drive system or electric drive system until the corresponding system reaches the speed corresponding to the operation command. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com