Ferritic-martensitic non-quenched and tempered steel, high-strength bolt and preparation method thereof

A technology of non-quenched and tempered steel and high-strength bolts, used in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problem of difficulty in reducing the permanent elongation of non-quenched and tempered steel, and achieve the goal of improving stability and reducing permanent elongation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments and examples, and the advantages and various effects of the present invention will be presented more clearly. Those skilled in the art should understand that these specific implementations and examples are used to illustrate the present invention, not to limit the present invention.

[0022] Throughout the specification, unless otherwise specified, terms used herein should be understood as commonly used in the art. Therefore, unless otherwise defined, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. In case of conflict, this specification shall take precedence.

[0023] Unless otherwise specified, various raw materials, reagents, instruments and equipment used in the present invention can be purchased from the market or prepared by existing methods.

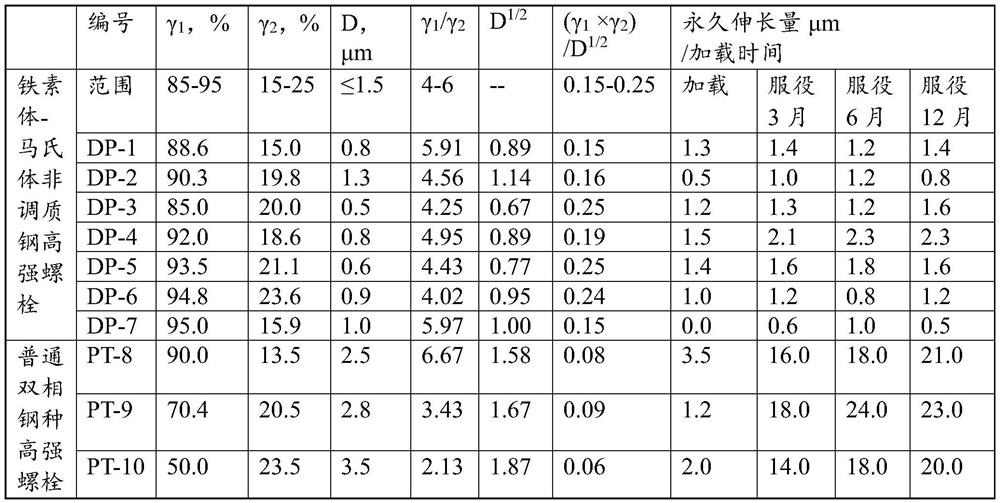

[0024] An e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com