Sampling device

A technology of sampling device and shaft installation, which is applied in the direction of sampling device, etc., to avoid various unpleasant smells, maintain the original tissue properties, avoid artificial freezing and thawing damage and waste samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

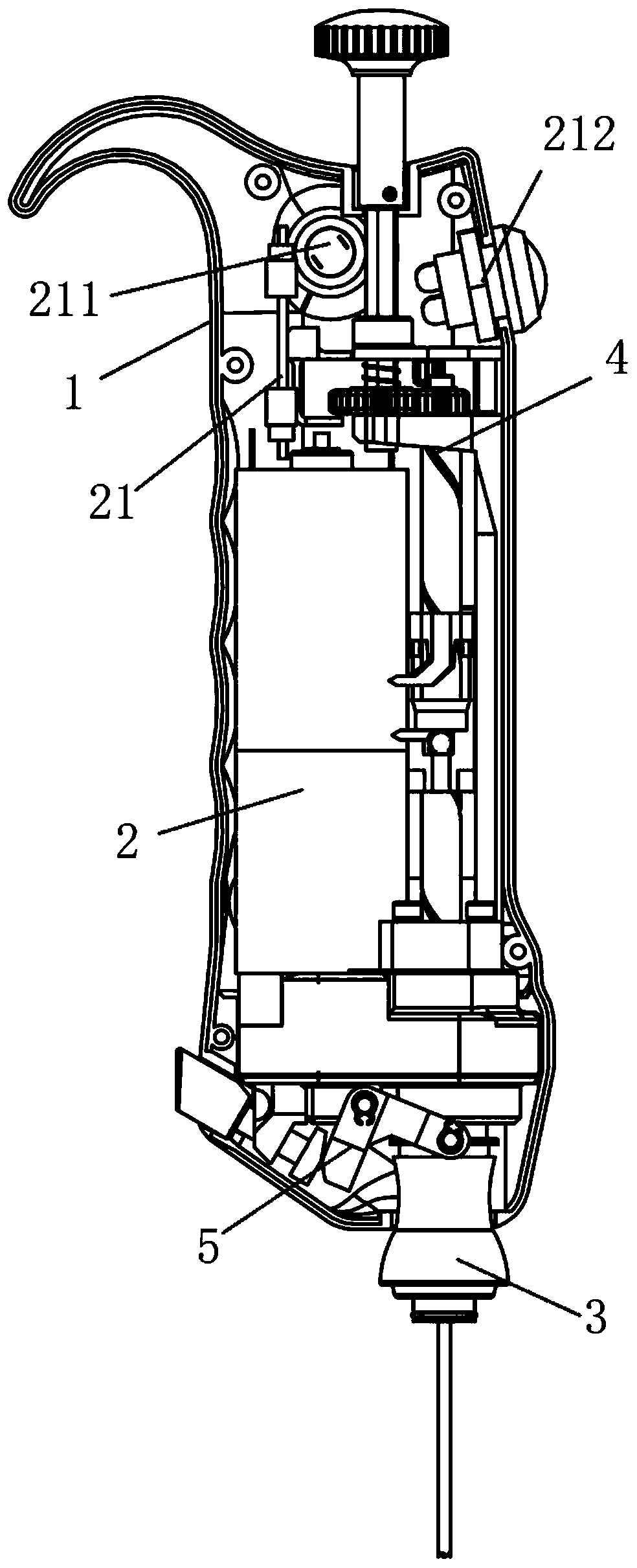

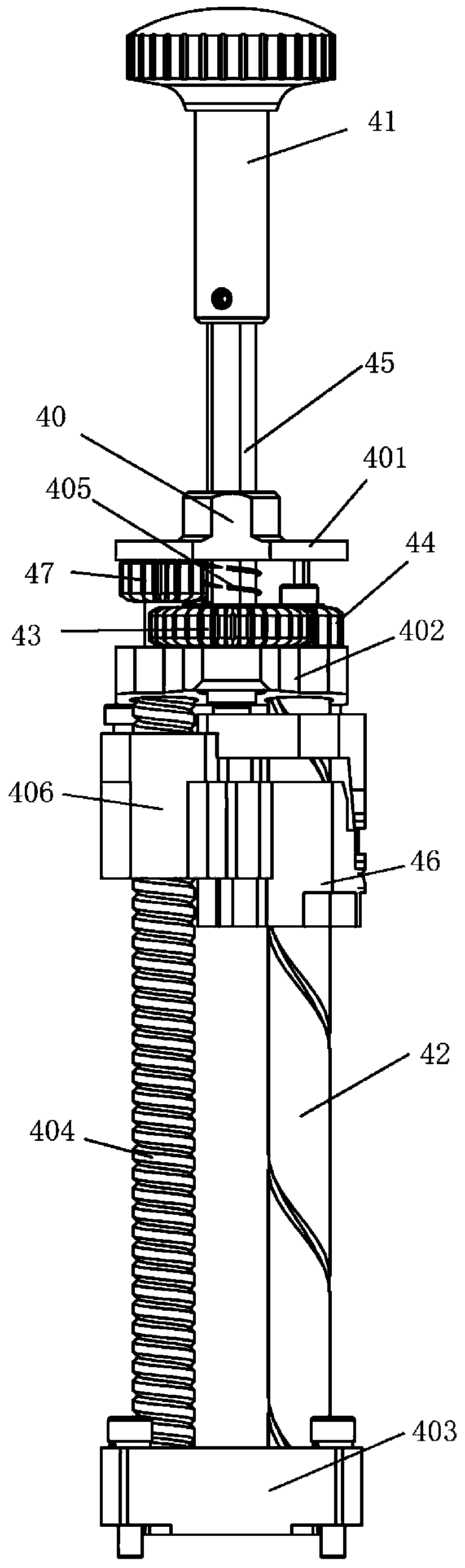

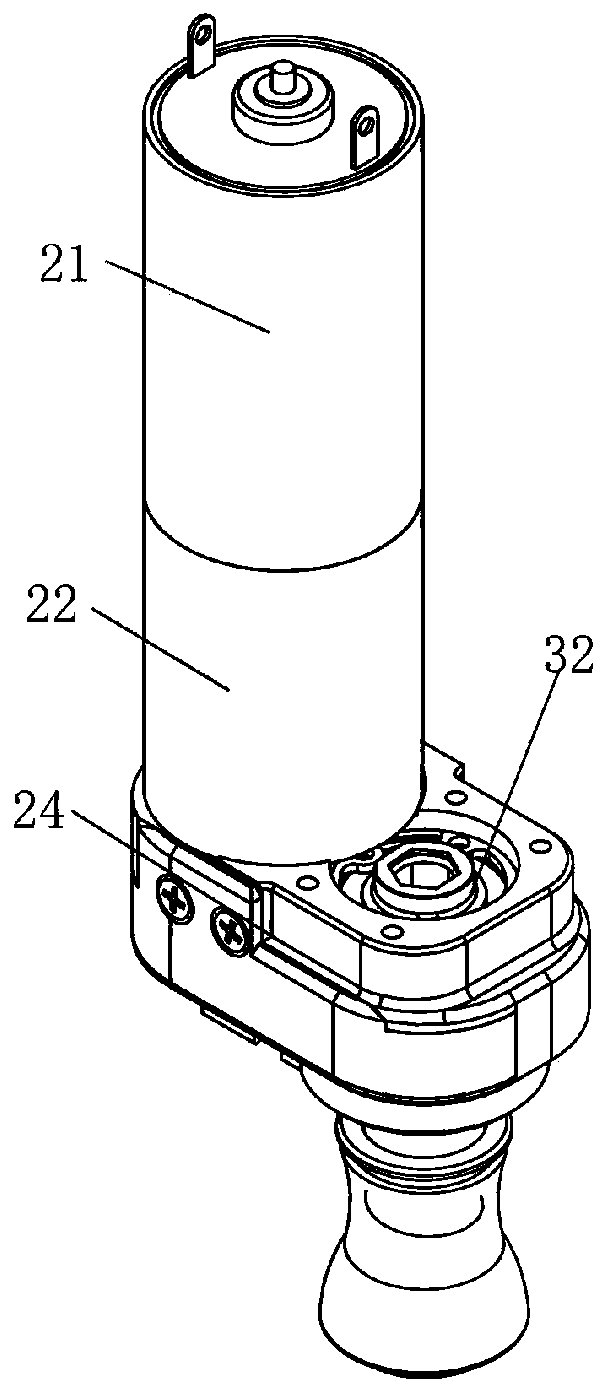

[0027] Such as Figure 1 to Figure 8 As shown, a sampling device includes a housing 1 in which a drive assembly 2, a drill bit assembly 3, and a material ejection assembly 4 are provided. The drill bit assembly includes a drill needle 31 and a drill needle installation A shaft 32, the drill pin mounting shaft is connected to the drive assembly and can drive the drill pin to rotate under the drive of the drive assembly. The withdrawal assembly includes a knob 41 and a withdrawal screw 42. The withdrawal screw is connected to the The drill bit assembly is connected, and the knob 41 is connected with the material withdrawal screw rod and can drive the material withdrawal screw rod to rotate for material withdrawal.

[0028] In this embodiment, the return assembly includes a mounting bracket 40, the mounting bracket is fixed in the housing, a cover plate 401 is arranged above the mounting bracket, the knob is arranged above the cover plate, and the cover plate is arranged There is a...

Embodiment 2

[0038] Such as Figure 1 to Figure 8 As shown, a sampling device includes a housing 1 in which a drive assembly 2, a drill needle assembly 3, and a material ejection assembly 4 are provided. The drill needle assembly includes a drill needle 31 and a drill needle installation A shaft 32, the drill pin mounting shaft is connected to the drive assembly and can drive the drill pin to rotate under the drive of the drive assembly. The withdrawal assembly includes a knob 41 and a withdrawal screw 42. The withdrawal screw is connected to the The drill bit assembly is connected, and the knob 41 is connected with the material withdrawal screw rod and can drive the material withdrawal screw rod to rotate for material withdrawal.

[0039] In this embodiment, the return assembly includes a mounting bracket 40, the mounting bracket is fixed in the housing, a cover plate 401 is arranged above the mounting bracket, the knob is arranged above the cover plate, and the cover plate is arranged Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com