Device having a main support and an equipment support

A kind of equipment support and basic technology, applied in the direction of transmission device, mechanical equipment, lifting device, etc., can solve the problems of expensive size design of mechanism and driving parts, acceleration and force application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

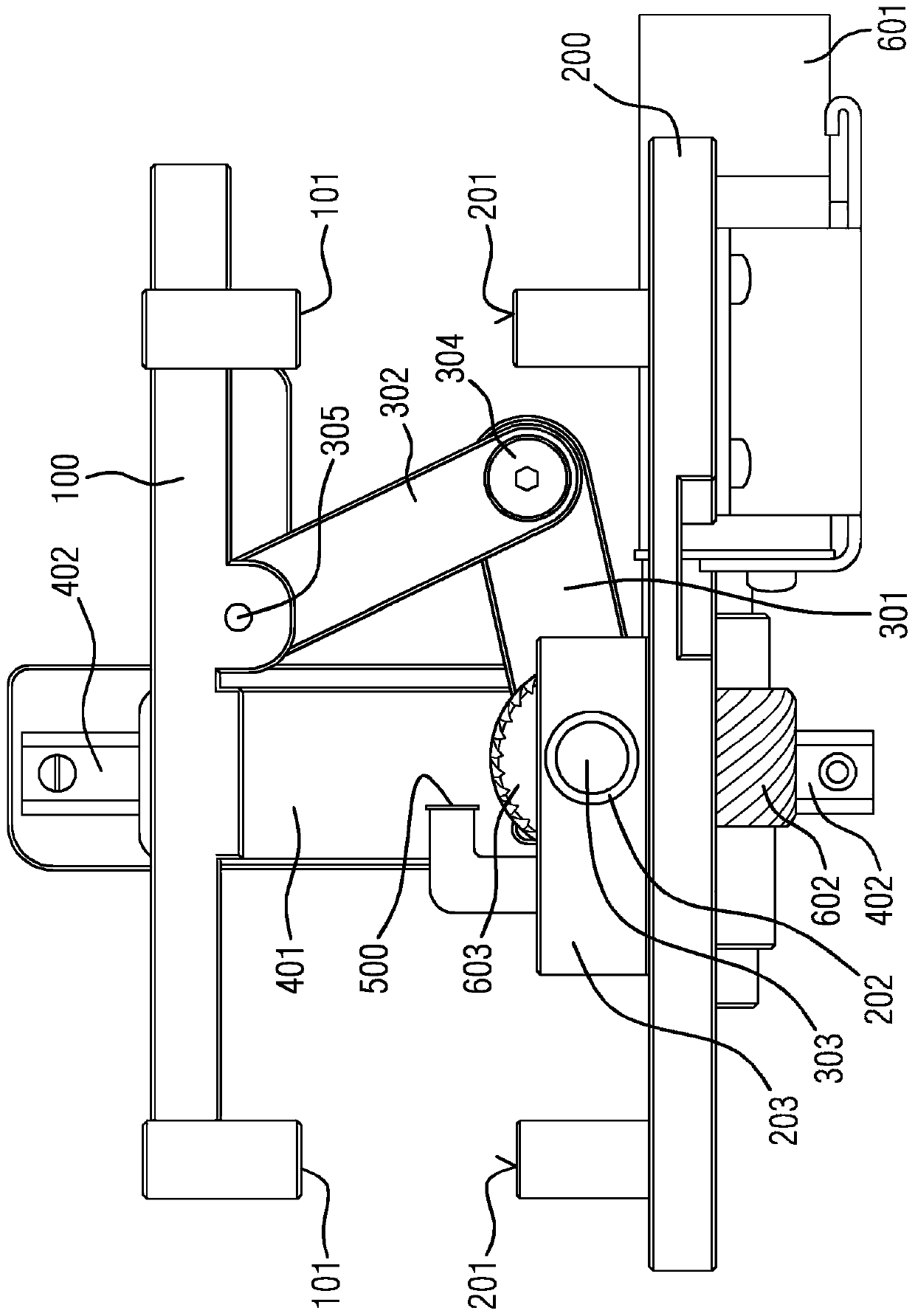

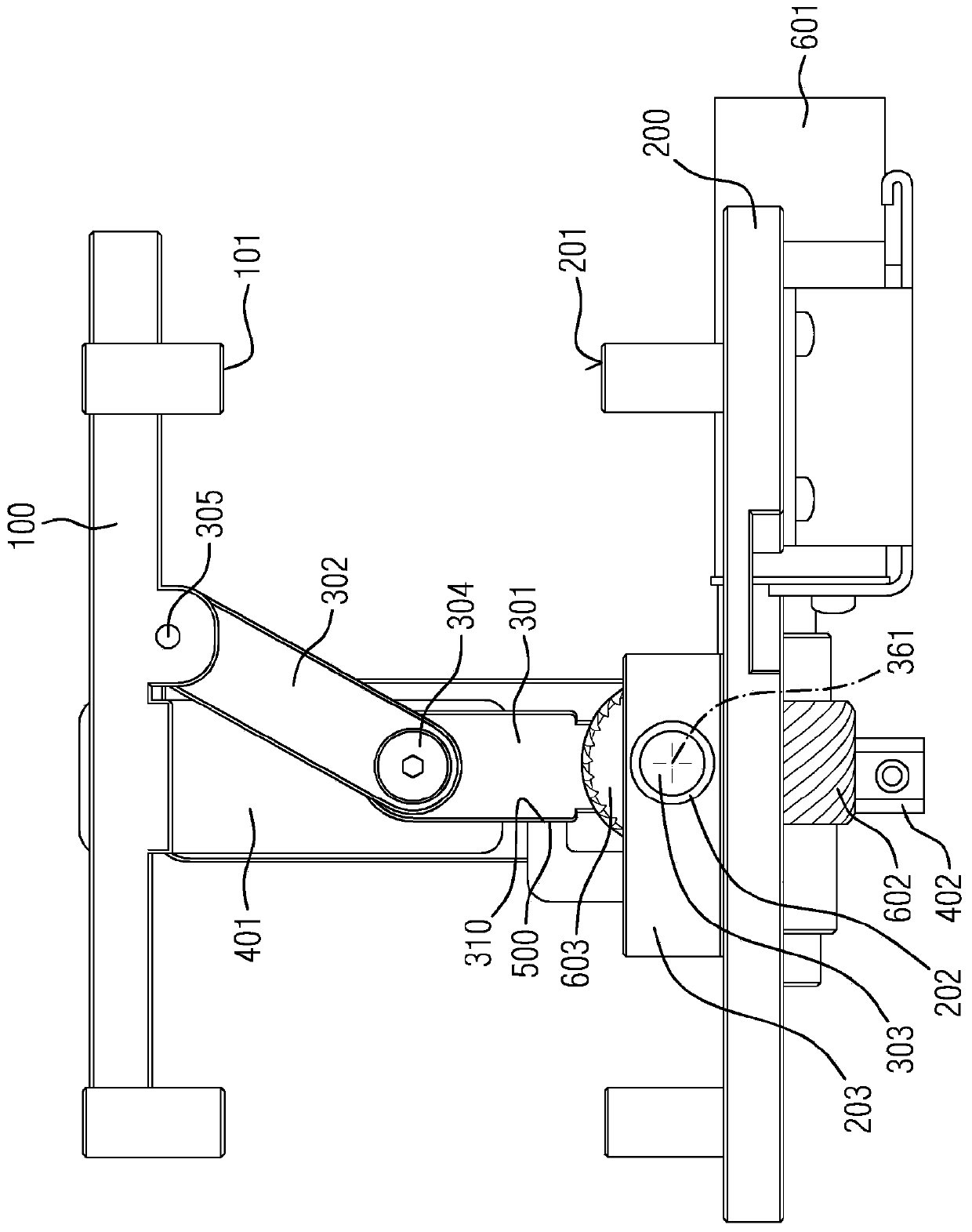

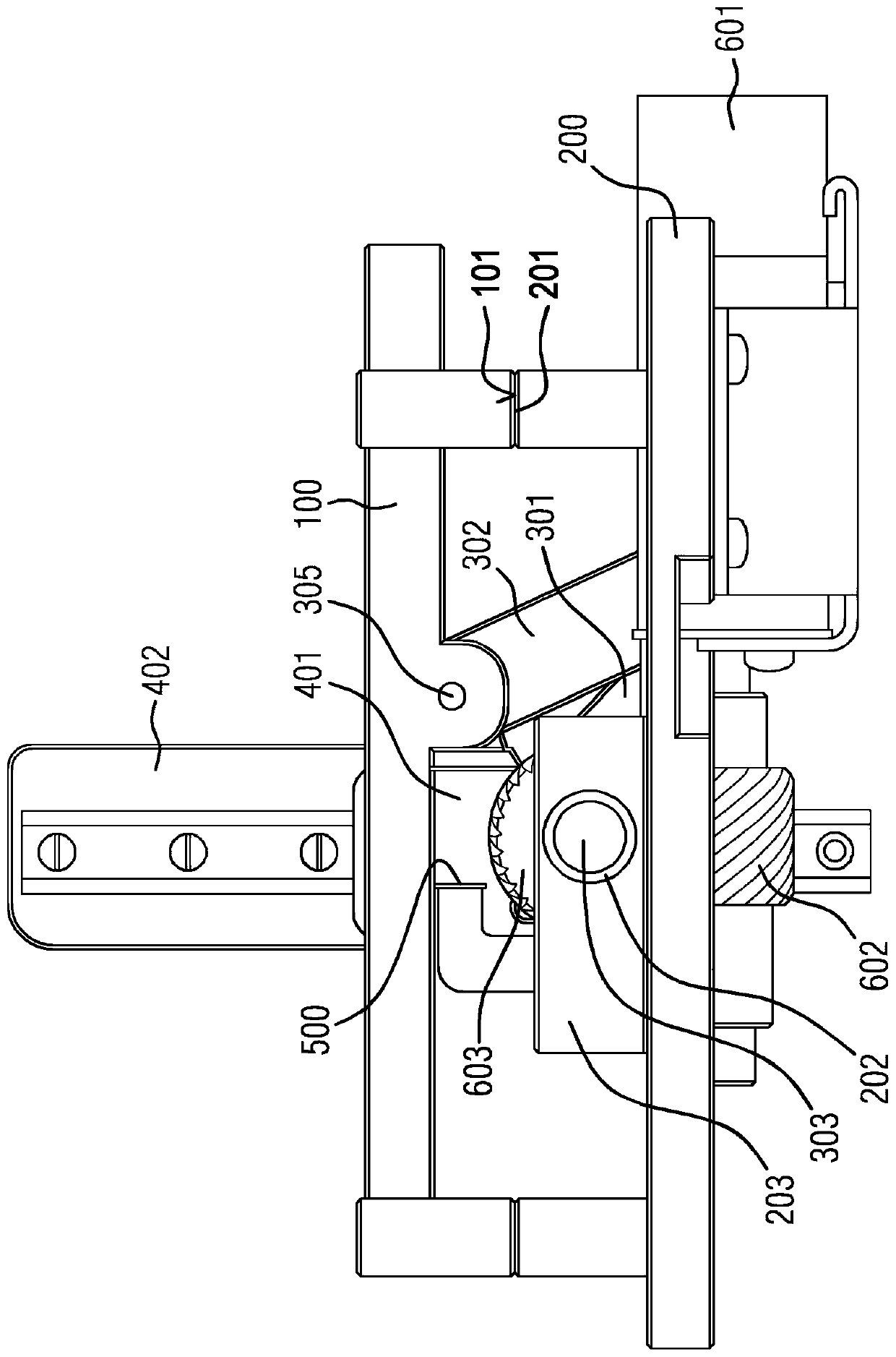

[0031] exist Figure 1-3It can be seen in the equipment support 100, the basic support 200, the first rocker 301, the connecting rod 302, the guide device with the guide slider 401 and the guide rail 402, the stop part 500, the drive in the form of the motor 601, the drive with the worm gear 602 and spur gear 603 for the first transmission. A support frame 101 is formed on the device support 100 , and a first support surface 201 is formed on the base support 200 . in the first position ( image 3 ), the equipment support 100 abuts against the first support surface 201 of the base support 200 through the support frame 101 . However, the support frame 101 and / or the first support surface 201 can also be a separate component, if they are rigidly connected to the equipment support 100 or the base support 200 , respectively. The equipment support 100 and / or the base support 200 can also be designed in such a way that if the support functionality of the equipment support 100 on t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap