I-shaped steel arch frame connecting steel plate welding positioning clamping device

A technology for connecting steel plates and I-beams, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of unqualified welding quality of I-beams, dislocation of reserved bolt holes in I-beams, and insufficient supporting thickness. , to achieve the effect of improving the efficiency and quality of docking, improving the quality of construction, and ensuring the quality of the loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

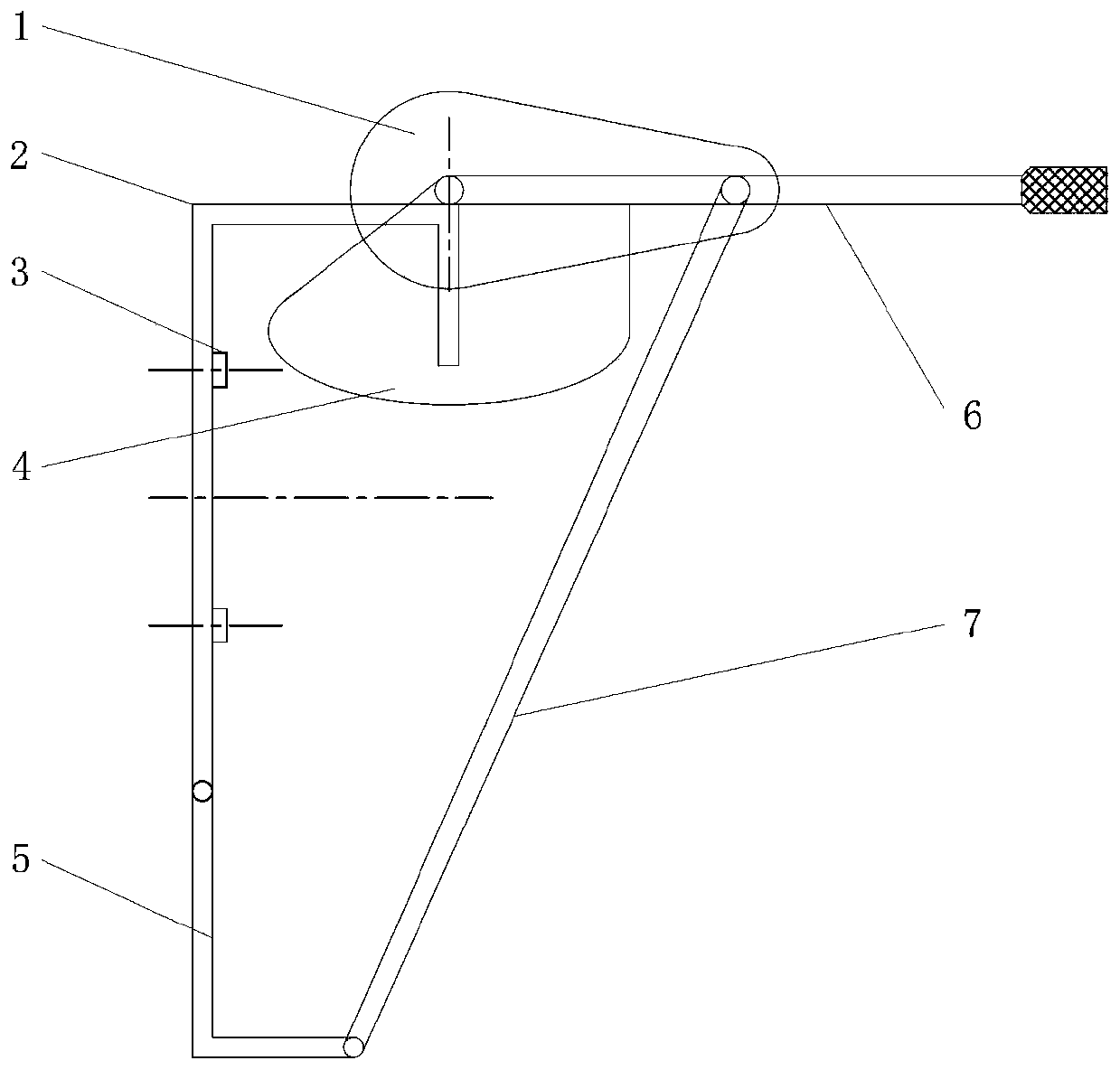

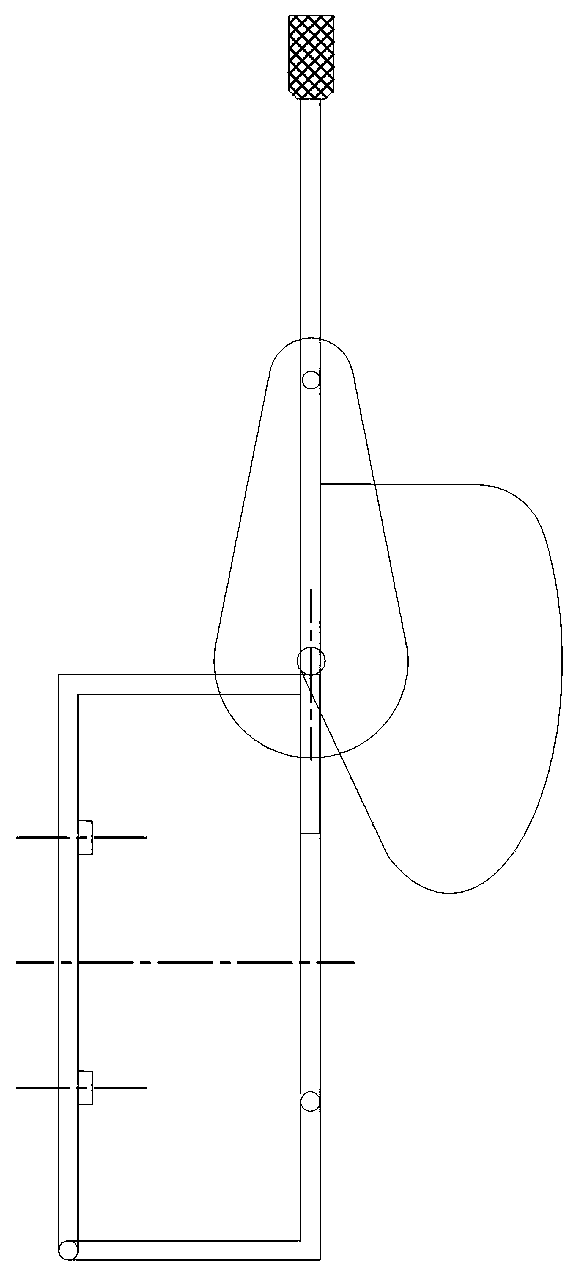

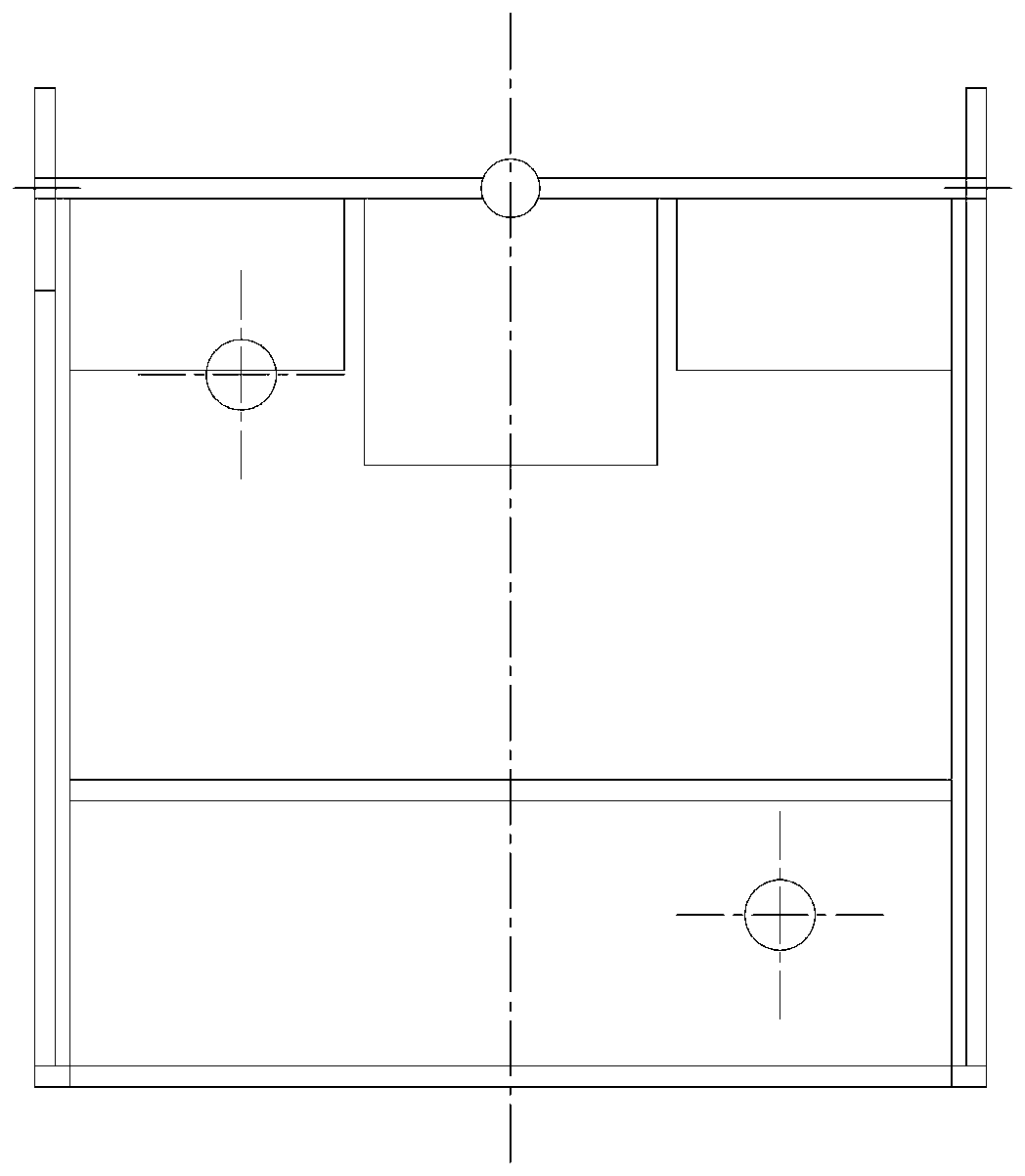

[0018] An I-shaped steel arch frame connecting steel plate welding positioning and clamping device, including a first connecting rod 1, a welding fixture bracket 2, a positioning pin 3, a pressing block 4, a movable limit block 5, a handle 6 and a second connecting rod 7 .

[0019] The sections of the welding fixture bracket 2 and the movable limit block 5 are both L-shaped structures, and the welding fixture bracket 2 and the movable limit block 5 are connected by hinges; the middle of the welding fixture bracket 2 and the movable limit block 5 is a steel plate structure , the steel plate structure of the welding fixture bracket 2 is welded and fixed with two positioning pins 3, and the two positioning pins 3 are arranged in parallel and staggered rows; the handle 6 is a T-shaped structure, and the two ends of the handle 6 connect the first connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com