Elevator oil pressure buffer test tower chain plate transmission and distribution assembly line

A technology of hydraulic buffers and buffers, applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve problems such as the need for operation, high weight, and deviation of connection positions, so as to reduce the concentration of stress. force conditions, reduction of operating time, effect of dispersing impact forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

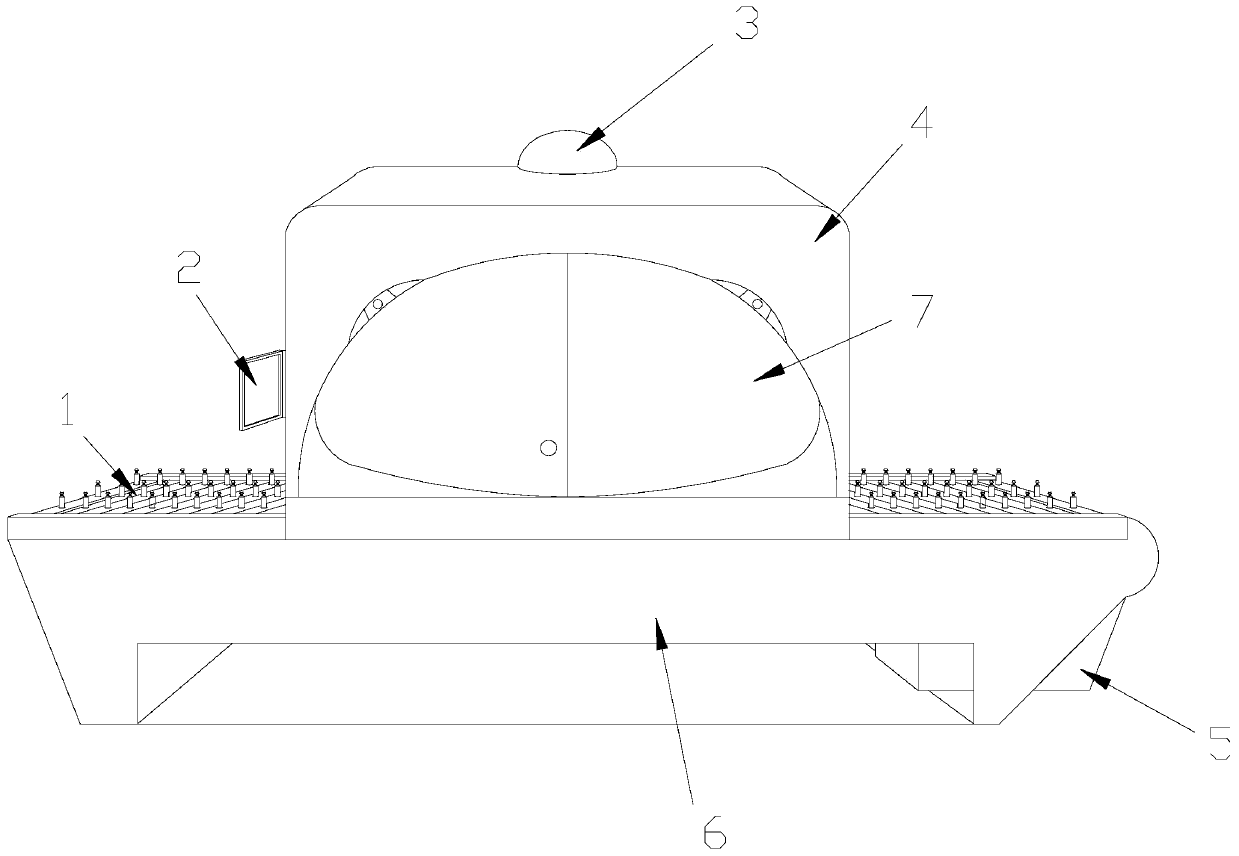

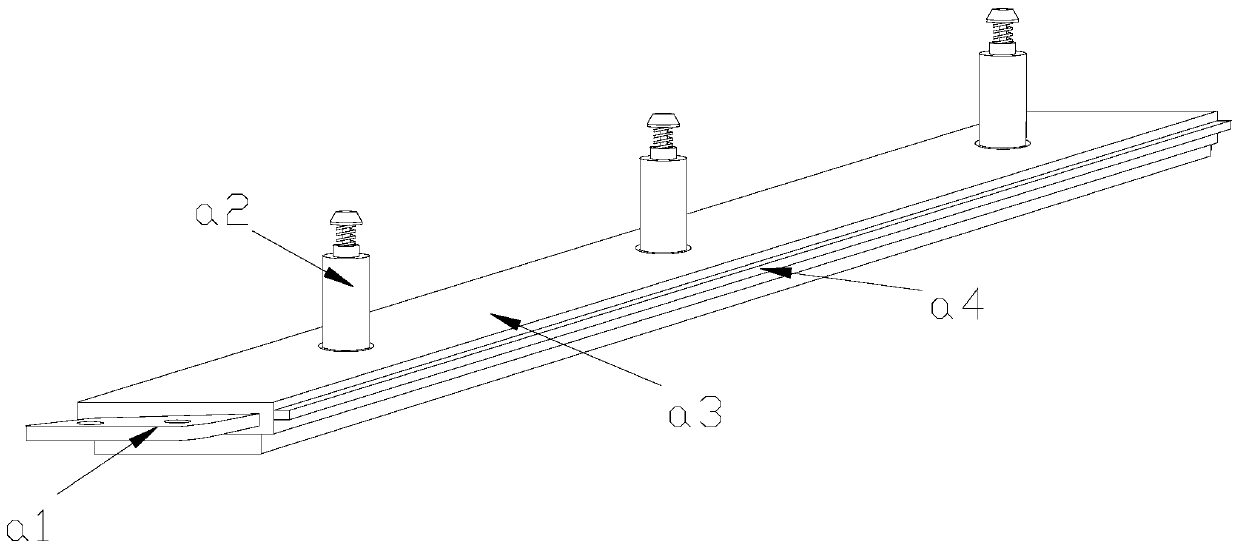

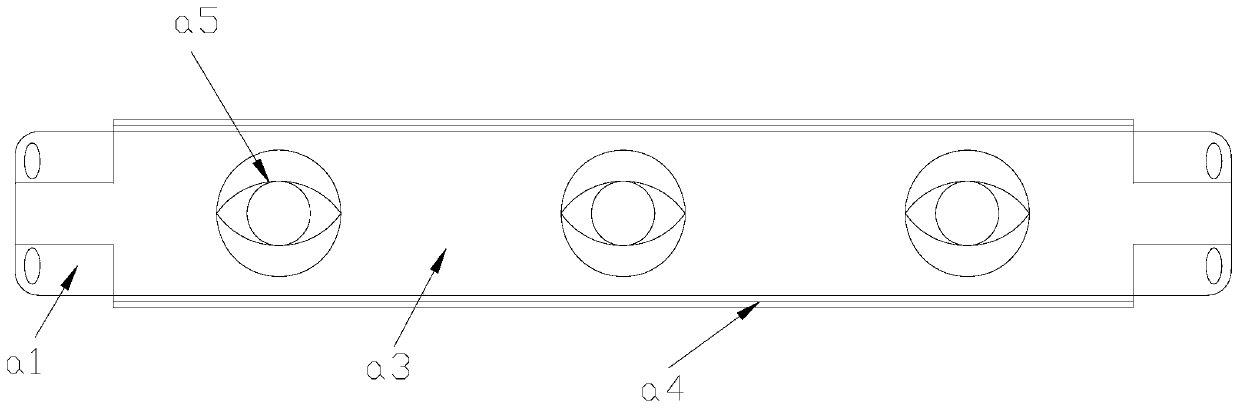

[0029] as attached figure 1 to attach Figure 9 Shown:

[0030] The invention provides an elevator hydraulic buffer test tower chain plate transmission and distribution line, the structure of which includes a chain plate transmission and distribution stabilization device 1, a control board 2, a test tower 3, a testing machine 4, an oil pressure buffer collection box 5, The base 6, the swing protection door 7, the chain plate transmission and distribution stabilization device 1 is installed on the base 6 by embedding, the test tower 3 is inserted and fixedly installed inside the top of the testing machine 4, the oil pressure buffer The collection box 5 is located on the right side of the base 6, the control plate 2 is movably installed on the left side of the testing machine 4, the front end of the testing machine 4 is provided with a rotating protective door 7, and the bottom end of the testing machine 4 is welded. The way is fixedly connected to the top of the base 6.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com