Aerobic organic fertilizer fermentation equipment

A technology of organic fertilizer and fermentation equipment, applied in the direction of organic fertilizer equipment, organic fertilizer preparation, organic fertilizer, etc., can solve the problems of incomplete fermentation, uneven fertilizer turning, large area occupied by fertilizer piles, etc., and increase the contact area , Avoiding excessive occupation of area, improving fermentation efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

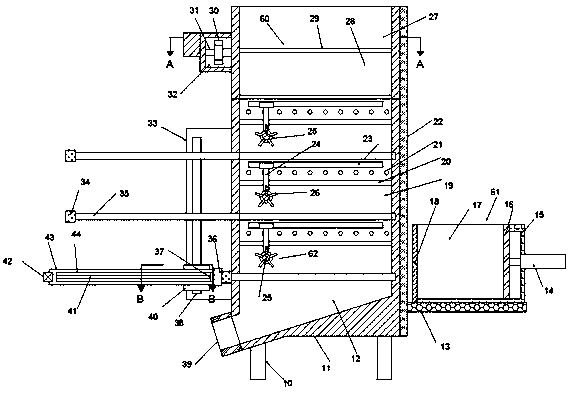

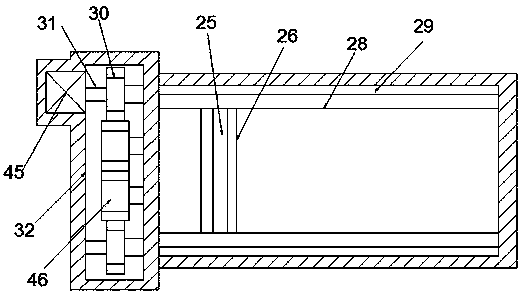

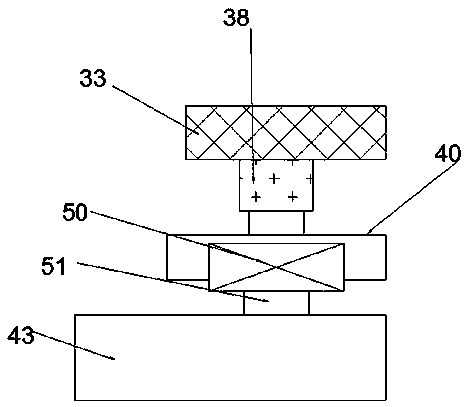

[0016] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0017] A kind of aerobic organic fertilizer fermentation equipment described in conjunction with accompanying drawing 1-4, mainly comprises fermentation case 11, and described fermentation case 11 lower surface is fixedly provided with support leg 10, and described fermentation case 11 is provided with upward opening Storage chamber 27, a valve mechanism 60 is provided in the storage chamber 27, a feeding mechanism 61 is provided on the right side of the fermentation tank 11, and the feeding mechanism 61 sends fertilizer into the storage chamber 27, and the supporting legs 10 There is a fermentation chamber 19 located on the lower side of the storage chamber 27, the fermentation chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com