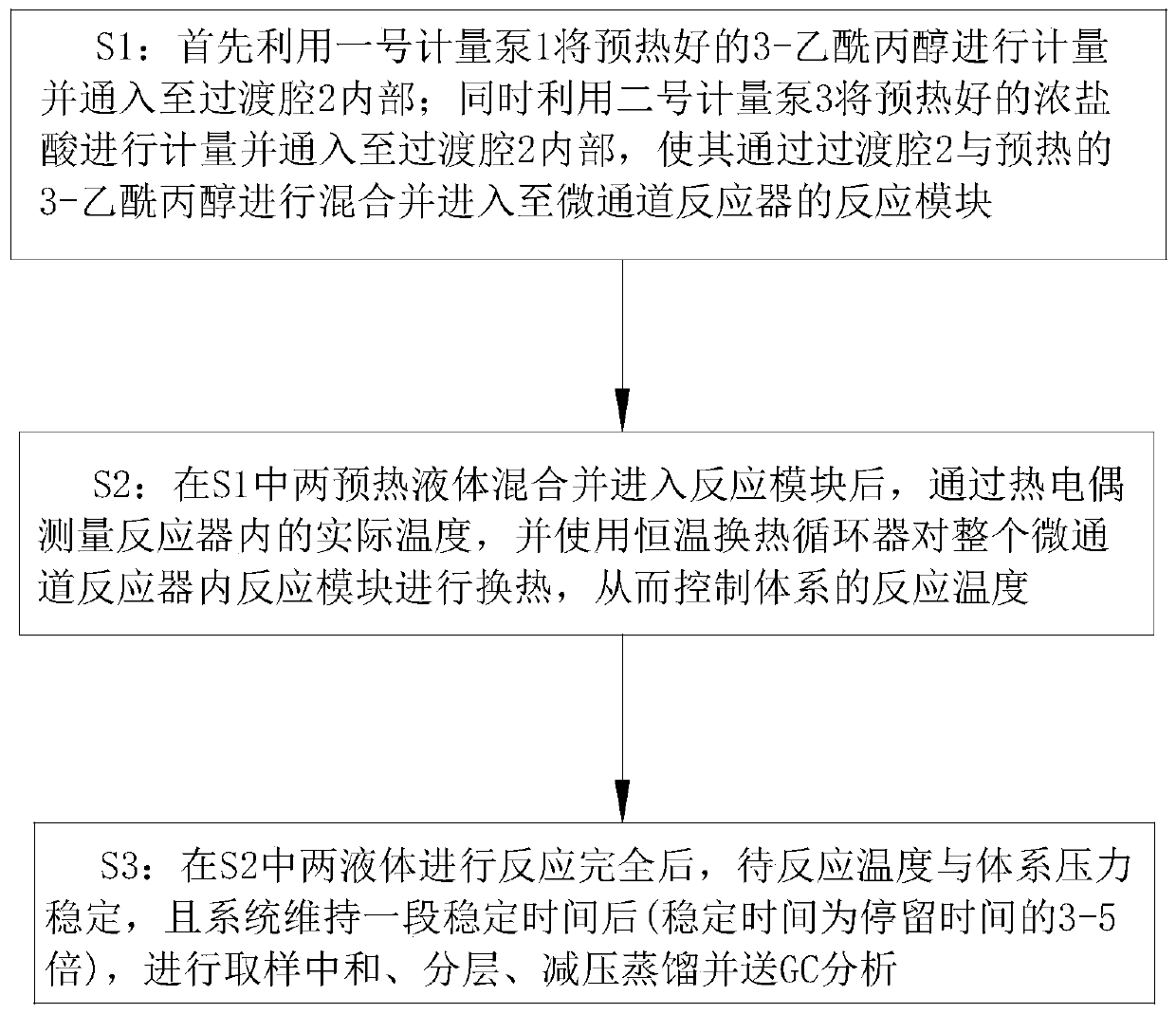

Process method for preparing 5-chloro-2-pentanone by using micro-channel reactor

A technology of microchannel reactor and process method, which is applied in the field of chemical preparation, can solve the problems of vulnerable parts, no flow cut-off function, and influence on the preparation of 5-chloro-2-pentanone, and achieve the effect of reducing waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

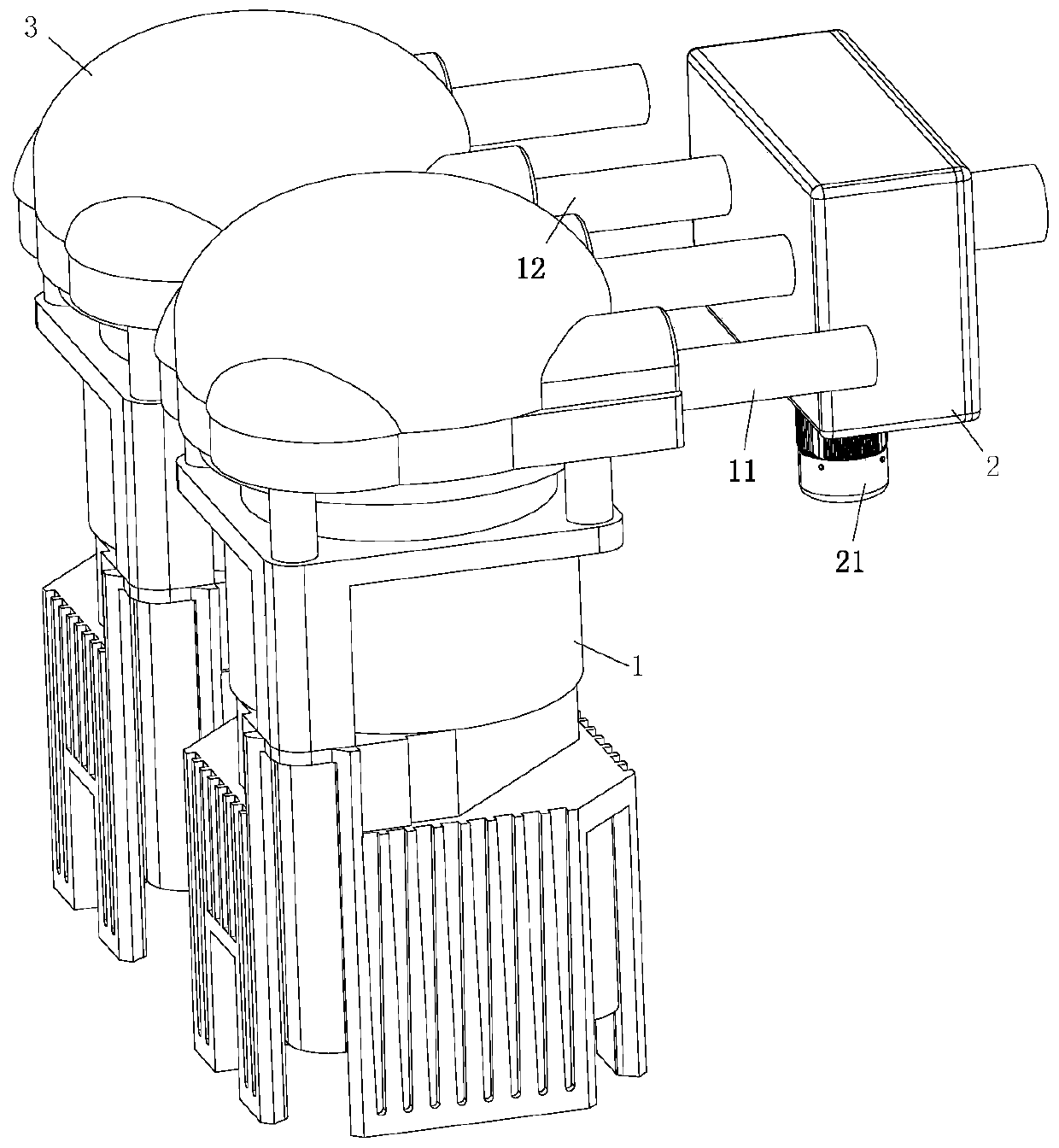

Embodiment approach

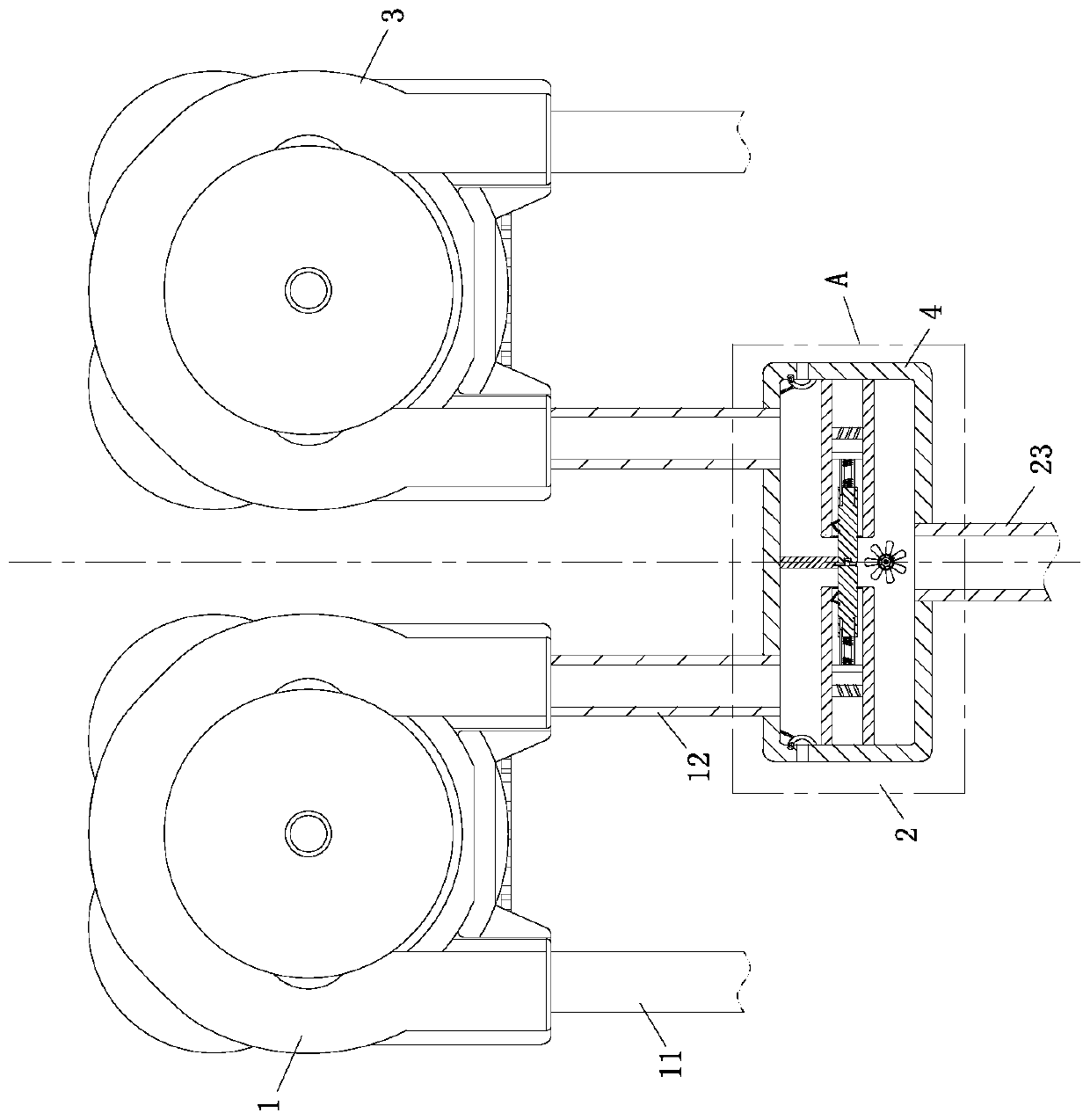

[0032] As an embodiment of the present invention, a rotating plate 54 is hinged on the side wall of the cut-off chamber 5 corresponding to the side of the baffle plate 6 close to the outlet pipe 12, and the rotating plate 54 is composed of an inner sealing plate 55 and an outer sealing plate 56. Composition, and the inner sealing plate 55 and the outer sealing plate 56 ends are provided with a sealing layer 57 made of elastic rubber material, the side wall of the baffle plate 6 corresponding to the bottom end of the rotating plate 54 is provided with an inner sealing plate 55 is a sealing groove 61 that matches the outer sealing plate 56; during operation, when the baffle plate 6 realizes the shut-off function, the bottom of the inner sealing plate 55 and a sealing groove 61 close to the electromagnet 51 are locked together, so that the inner sealing The sealing layer 57 at the bottom of the plate 55 cooperates with the sealing groove 61 to seal the inside of the cut-off chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com