A UV curing adhesive for LED curing of curved screen film

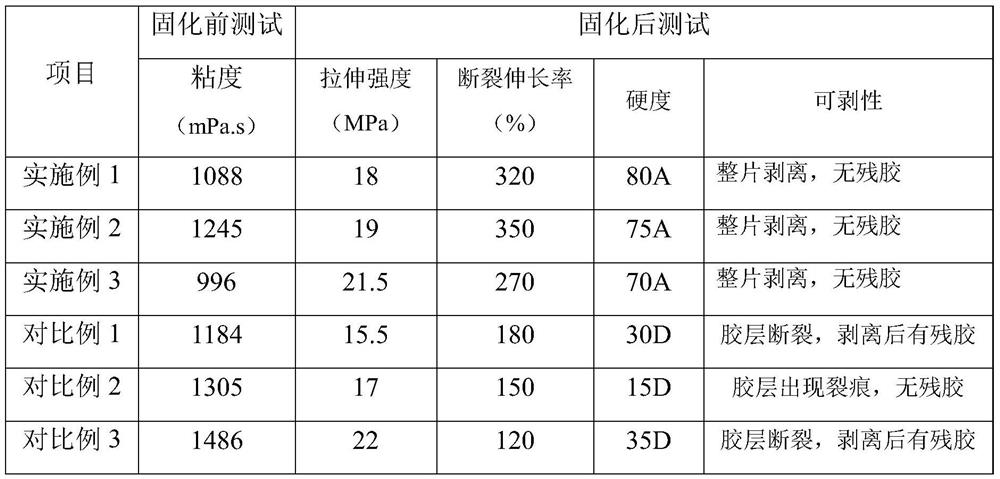

A technology of ultraviolet light and curved screen, which is applied in the direction of adhesive, adhesive type, polyurea/polyurethane adhesive, etc., can solve the problem of weak adhesion of the edge of the tempered film, achieve low hardness of the adhesive layer, low heat release, The effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

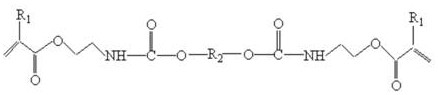

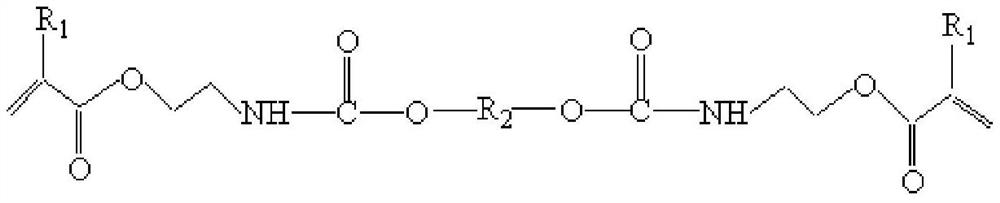

[0022] Low viscosity difunctional urethane acrylates are prepared according to the following steps:

[0023] Add 2.2 moles of MOI into a three-necked flask with a thermometer, heat and stir, and when the temperature reaches 60°C, add 1 mole of polyethylene glycol 1000, add the catalyst dibutyltin dilaurate, raise the temperature to 70°C, and react for 2 to 3 hours. Use an infrared spectrometer to analyze the content of OH groups. When the peak of OH completely disappears, stop the reaction to obtain low-viscosity difunctional polyurethane acrylate.

[0024] A UV curing adhesive for LED curing of curved screen film, prepared according to the following steps: raw materials in parts by weight, 32 parts of Sartomer's CN8881, 15 parts of the above-mentioned self-made low-viscosity bifunctional polyurethane polyurethane Add acrylate, 20 parts of isobornyl acrylate, 24 parts of tetrahydrofuran acrylate, 0.05 parts of p-benzoquinone, and 2.15 parts of silane coupling agent KH570 into ...

Embodiment 2

[0026] Low viscosity difunctional urethane acrylates are prepared according to the following steps:

[0027] Add 2.2 moles of AOI into a three-necked flask with a thermometer, heat and stir, when the temperature reaches 55°C, add 1 mole of polypropylene glycol 600, add the catalyst stannous octoate, raise the temperature to 75°C, react for 2 to 3 hours, and analyze with an infrared spectrometer When the peak of OH groups disappears completely, the reaction is stopped to obtain low-viscosity difunctional polyurethane acrylate.

[0028] A UV-curable adhesive used for LED curing of curved screen film, prepared according to the following steps: raw materials in parts by weight, 45 parts of BR-744BT from Dymax Corporation, 12 parts of the above-mentioned self-made low-viscosity bifunctional Polyurethane urethane acrylate, 10 parts of isobornyl methacrylate, 30 parts of isooctyl acrylate, 0.1 part of hydroquinone, and 1.4 parts of silane coupling agent KH551 are added to the mixer i...

Embodiment 3

[0030] Low viscosity difunctional urethane acrylates are prepared according to the following steps:

[0031] Add 1 mole of MOI and 1.2 moles of AOI into a three-necked flask with a thermometer, heat and stir, when the temperature reaches 65°C, add 1 mole of polyethylene glycol 1500, add the catalyst dibutyltin dilaurate, heat up to 75°C, and react After 2 to 3 hours, analyze the content of OH groups with an infrared spectrometer, and stop the reaction when the peak of OH completely disappears to obtain low-viscosity difunctional polyurethane acrylate.

[0032]A UV-curable adhesive for LED curing of curved screen film, prepared according to the following steps: raw materials in parts by weight, 54 parts of DR-U384 of Changxing Company, 30 parts of the above-mentioned self-made low-viscosity bifunctional polyurethane polyurethane Add acrylate, 30 parts of isooctyl methacrylate, 0.2 part of p-hydroxyanisole, and 1 part of silane coupling agent KH551 into the mixer in sequence. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com