Composite coupling beam damper and assembling method thereof

An assembly method and damper technology, which can be applied to building components, earthquake resistance, building types, etc., can solve problems such as the inability of dampers to be used well, and achieve the effect of solving insufficient energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

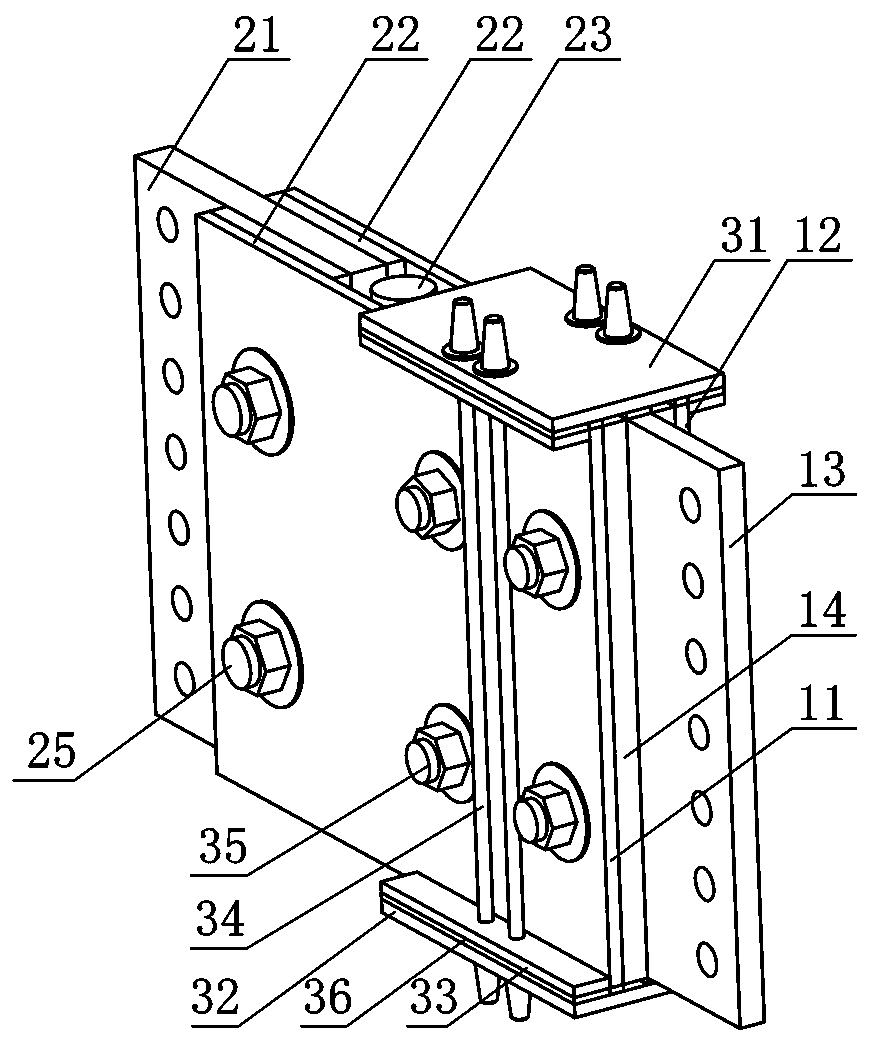

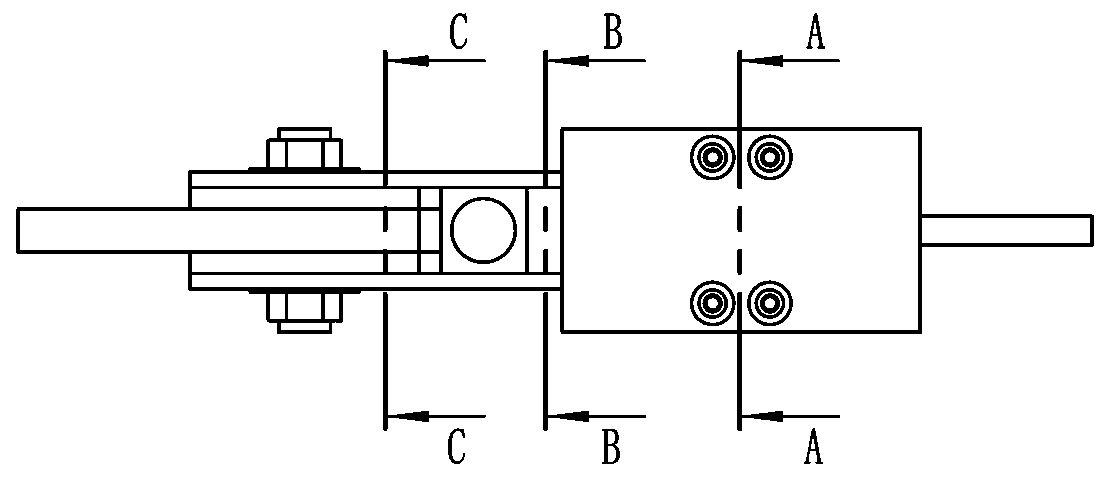

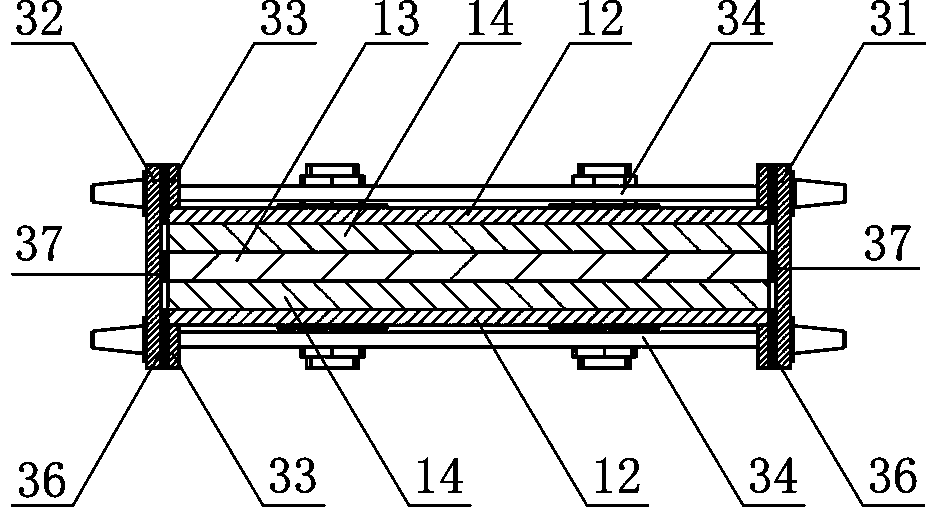

[0037] Such as Figure 1-5 As shown, a composite coupling beam damper includes a viscoelastic damper, and also includes an SMA damper and a reset friction damper, the SMA damper is connected in parallel at one end of the viscoelastic damper, and the reset friction damper connected in series to the other end of the viscoelastic damper.

[0038] viscoelastic damper

[0039] The viscoelastic damper includes a front constraining plate 11, a rear constraining plate 12 and a viscoelastic damping shear plate 13, and the viscoelastic damping shear plate 13 is bonded to the front constraining plate by a high damping viscoelastic material layer 14 11 and the rear restraint plate 12.

[0040] The viscoelastic damper belongs to the rate-dependent damper. It uses high-damping viscoelastic materials. It consumes energy in the case of small earthquak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com