Double-motor transmission for engineering vehicle

A dual-motor, engineering vehicle technology, applied in gear transmissions, components with teeth, belts/chains/gears, etc., can solve the problems of difficult layout of a single large-displacement motor, and achieve easy maintenance and low manufacturing costs. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

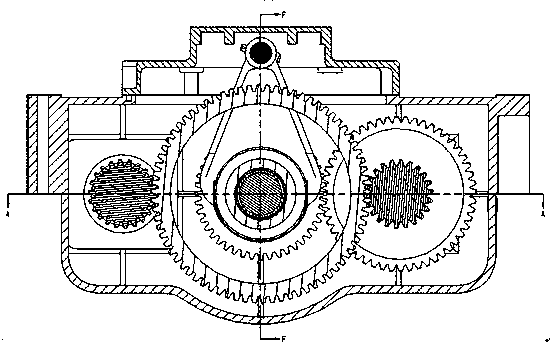

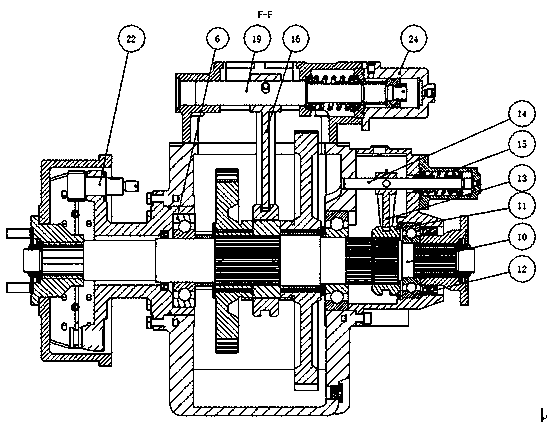

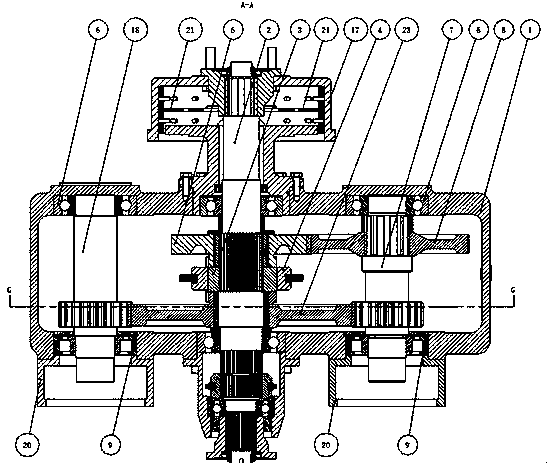

[0019] Embodiment: As shown in the figure, in the case body 1 of the transmission, three fixed shafts are installed through three sets of bearings 6 and 9, with No. 1 input gear shaft 7 and No. 2 input gear shaft 18 on both sides, and output shaft 2 in the middle. There are motor mounts 20 at the ends of No. 1 input gear shaft 7 and No. 2 input gear shaft 18; the middle section of output shaft 2 is empty with a first-gear output gear 23 and a second-gear output gear 5, and a first-gear output gear 23 and a second-gear output gear. 5 has a ring of splines on the inner surface of each, and the middle part of the output shaft 2 is equipped with a key tooth 3, the key tooth 3 is located between the first gear output gear 23 and the second gear output gear 5, the key tooth 3 is covered with a ring gear 4, and the key tooth 3 The outer diameter of the tooth 3 is the same as the spline outer diameter on the inner side of the first gear output gear 23 and the second gear output gear 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com