Frameless winding tool

A skeleton-free and tooling technology, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of high mold requirements, high skeleton material requirements, poor heat dissipation effect at the stator end, and achieve the effect of preventing scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

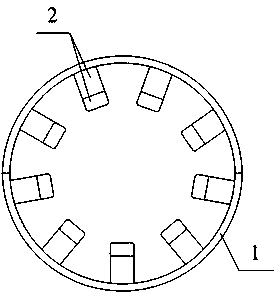

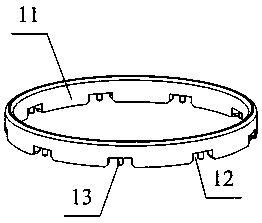

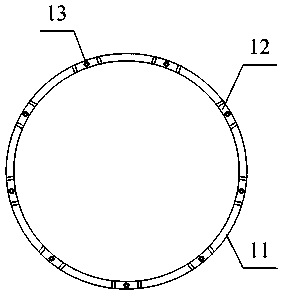

[0024] as attached figure 1 And attached figure 2 As shown, a skeletonless winding tooling includes a tooling ring structure 1 and a tooling plate structure 2, the tooling plate structure 2 is installed in the tooling ring structure 1; the tooling ring structure 1 includes a fixed ring 11. The installation groove 12 and the fixed end 13. The installation groove 12 is set on the lower side inside the fixed ring 11, and the fixed end 13 is integrally arranged in the middle part of the upper end of the inner wall of the installation groove 12.

[0025] as attached Figure 4 As shown, in the above embodiment, specifically, the tooling plate structure 2 includes a fixing plate 21, a connecting piece 22 and a connecting hole 23, and the connecting piece 22 is integrally arranged on the upper and lower parts outside the fixing plate 21 ; The connecting hole 23 is opened on the outside of the connector 22 inside.

[0026] In the above embodiment, specifically, the fixed plate 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com